A method for improving the performance of infrared and terahertz chips and infrared and terahertz chips

A chip performance, terahertz technology, applied in the direction of climate sustainability, nanotechnology for materials and surface science, sustainable manufacturing/processing, etc., can solve the performance limitations of terahertz modulators, detection speed and other performance limitations, Affect the overall performance of the terahertz system and other issues to achieve excellent localized surface plasmon resonance, controllable geometric dimensions, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

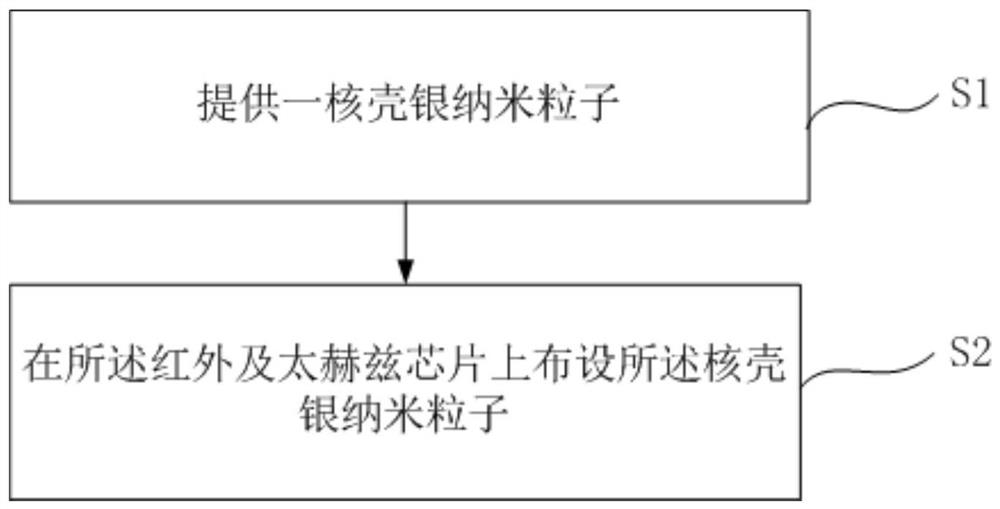

[0028] Such as figure 1 As shown, in step S1, the core-shell silver nanoparticles are subjected to the core structure precursor at a temperature of 100-170°C at least once in a reaction medium with a boiling point of 100-170°C in the presence of a protective agent Nano seed particles with core structure are obtained by reduction treatment; and at a reaction temperature of 25-100° C., shell structure precursors are added and at least one reduction treatment is performed to grow shell structures on the nano seed particles with core structure. The preparation method of the core-shell silver nanoparticles comprises:

[0029] (1) Synthesis of core-shell silver nanoparticles by chemical reduction method. First, weigh the precursor of the core structure (0.01-0.3 mg) and the reaction medium (10-40 mL), and mix them to obtain a mixed solution. Weigh an appropriate amount of protective agent and reducing agent and add to the above mixed solution to obtain a reaction solution. Stir th...

Embodiment 1

[0042] (1) Weigh silver nitrate (0.17g) and ethylene glycol (10mL) and mix them in a three-neck round bottom flask (capacity is 50mL), weigh polyvinylpyrrolidone (0.58g), fully dissolve in ethylene glycol (10mL ), inject it into the mixed solution of silver nitrate and ethylene glycol. The mixed solution was placed in an oil bath of a constant temperature magnetic stirrer, the temperature was set at 100° C., and the rotation speed was set at 800 rpm, and kept under these conditions for 30 minutes until the reaction was completed.

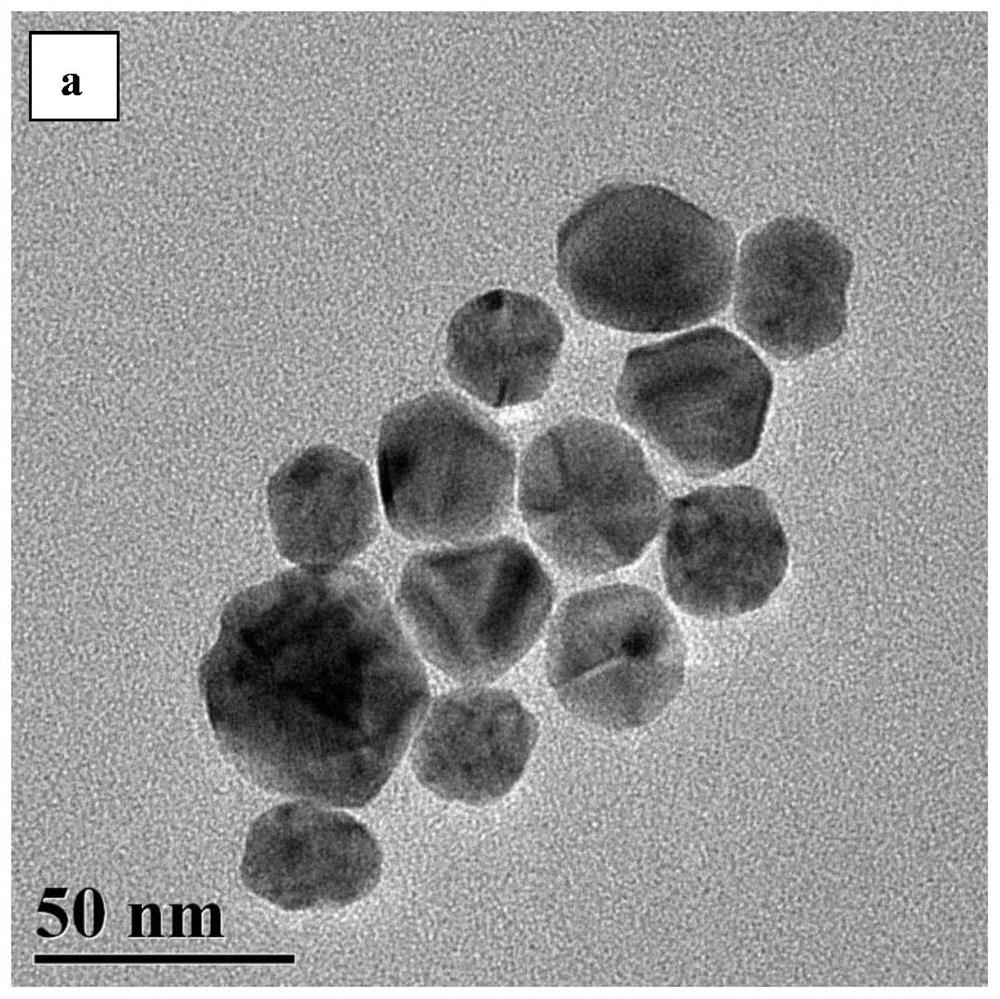

[0043] (2) After the reaction was completed, the mixture was cooled down to room temperature, and a certain amount of absolute ethanol was added to the obtained product, and the supernatant was removed after centrifugation (centrifugation conditions: 10000 rpm, 20 min), and the precipitate was washed with ethanol. After repeating the centrifugal washing process 2-3 times, the product was redispersed in deionized water. Obtain monodisperse silver na...

Embodiment 2

[0051] (1) Weigh silver nitrate (0.012g) and deionized water (20mL) and mix them in a three-neck round bottom flask (capacity is 100mL), and add trisodium citrate (5mmol), tannic acid (1mmol) and Deionized water (30 mL). Place the flask in an oil bath of a constant temperature magnetic stirrer, set the rotation speed to 500rpm, set the temperature to 130°C, heat until the mixed solution boils and keep it for 20-30min.

[0052] (2) Take 10 mL of sample from the reactant of step (1), and then add deionized water (5 mL) to the reactant. Then 2-3 mL trisodium citrate (2.5 mM), 2-3 mL tannic acid (0.625 mM) and 1-2 mL silver nitrate (6.25 mM) aqueous solution were added again. Continue to keep boiling and react for 20-30min. Repeat this step 2 to 10 times respectively to obtain silver nanoparticles with required particle size.

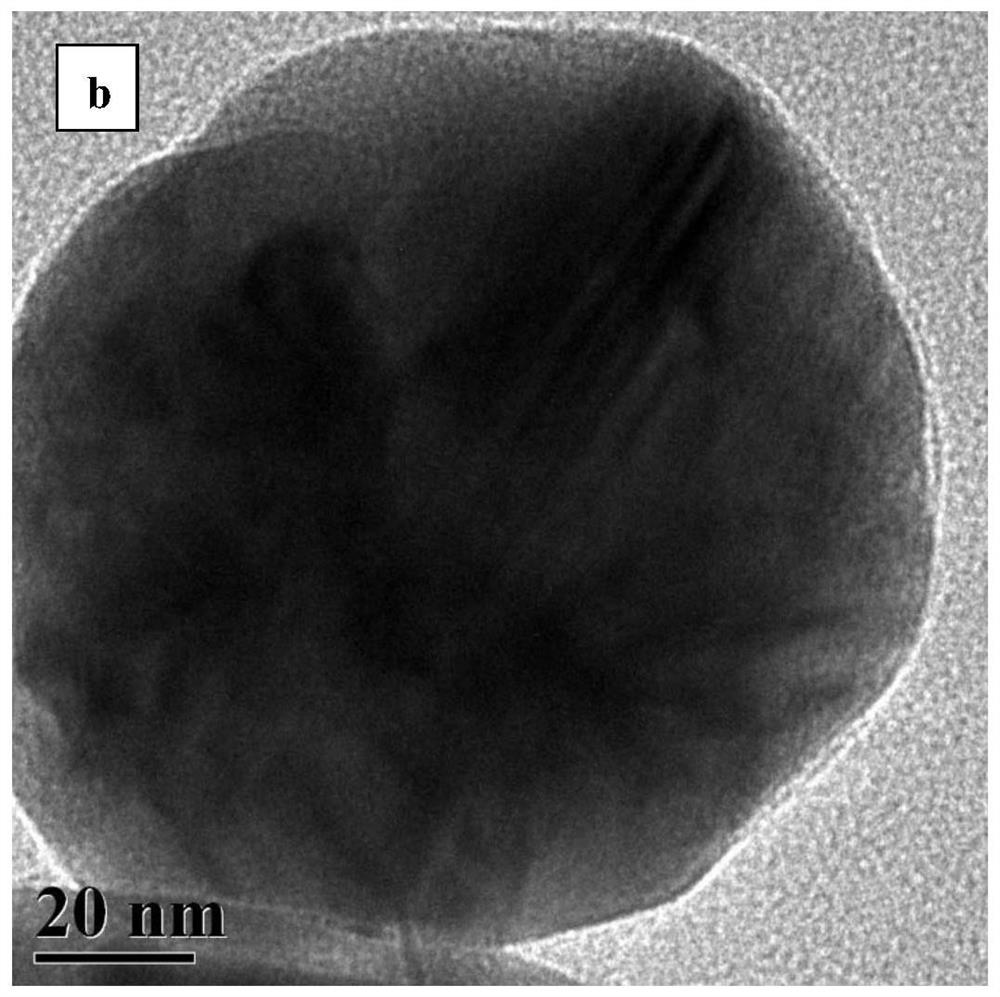

[0053] (3) 3 mL of the prepared silver nanoparticle solution was added to a mixture of 1.5 mL of absolute ethanol, 1 mL of ammonium hydroxide and deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com