Electric operating mechanism

A technology of electric operating mechanism and operating shaft, applied in the direction of protection switch operating/release mechanism, circuit, electrical components, etc., can solve the problems of large space occupation, complex structure design, short service life, etc., to increase the contact area, improve Intelligent management, the effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

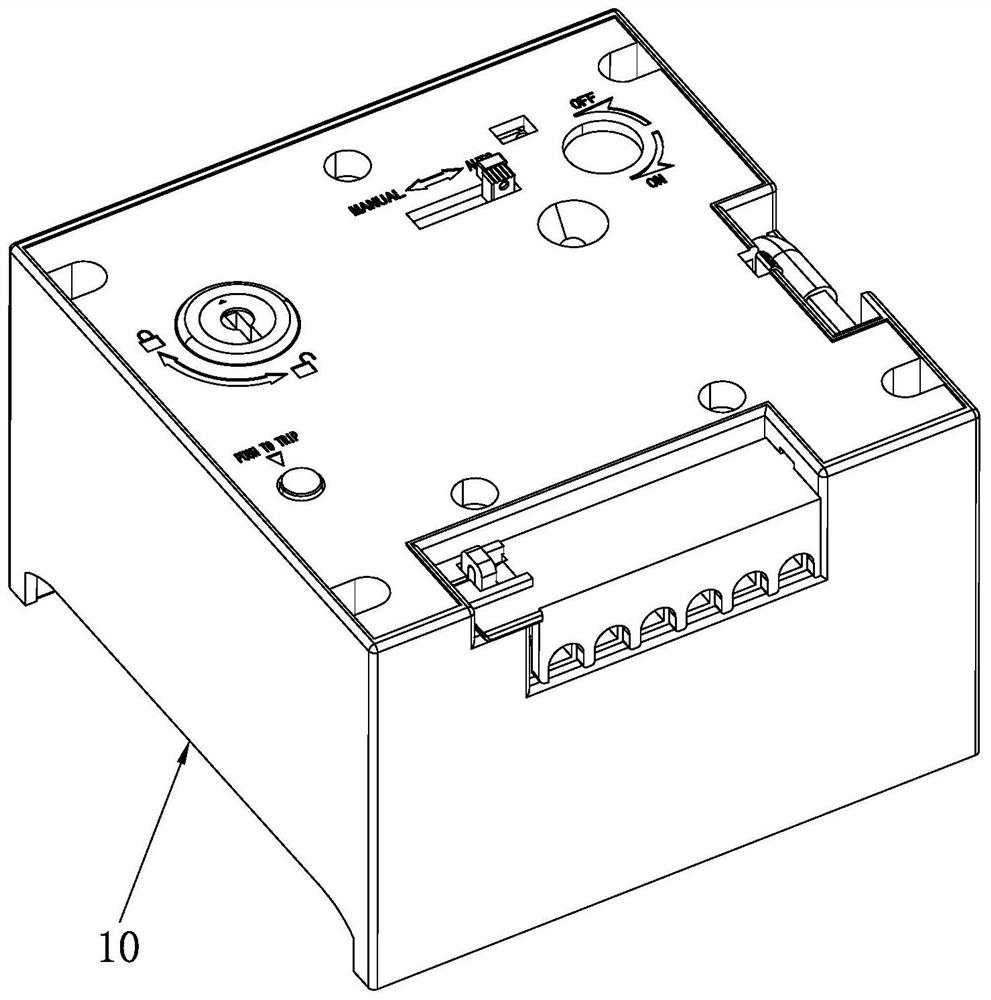

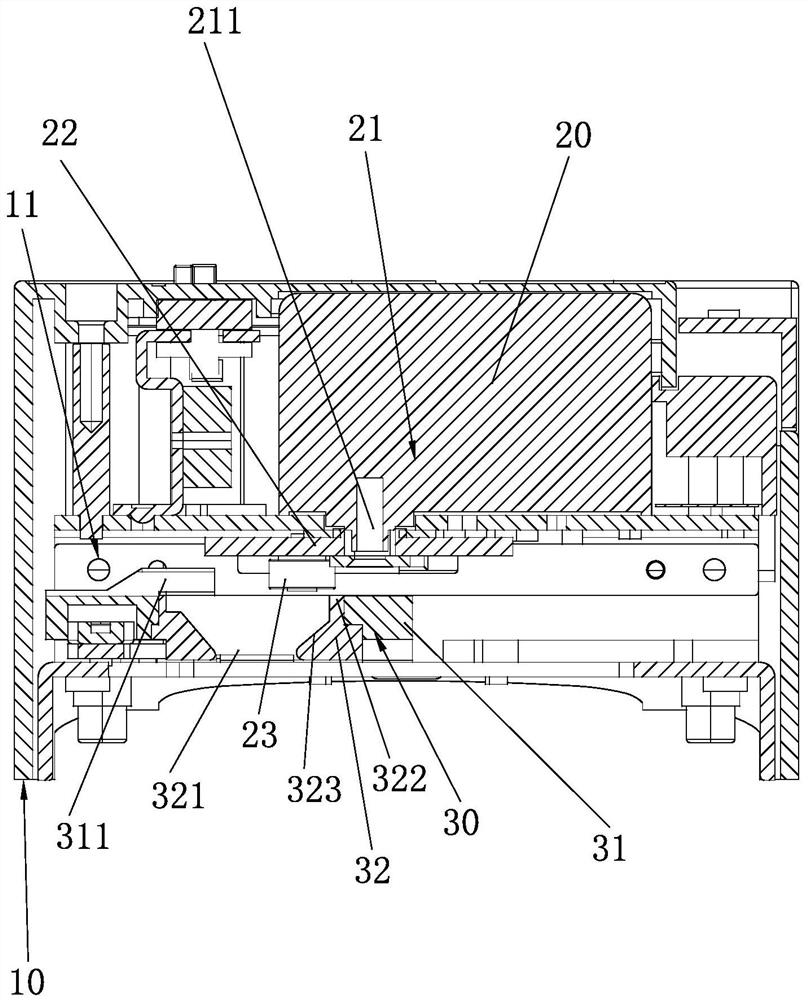

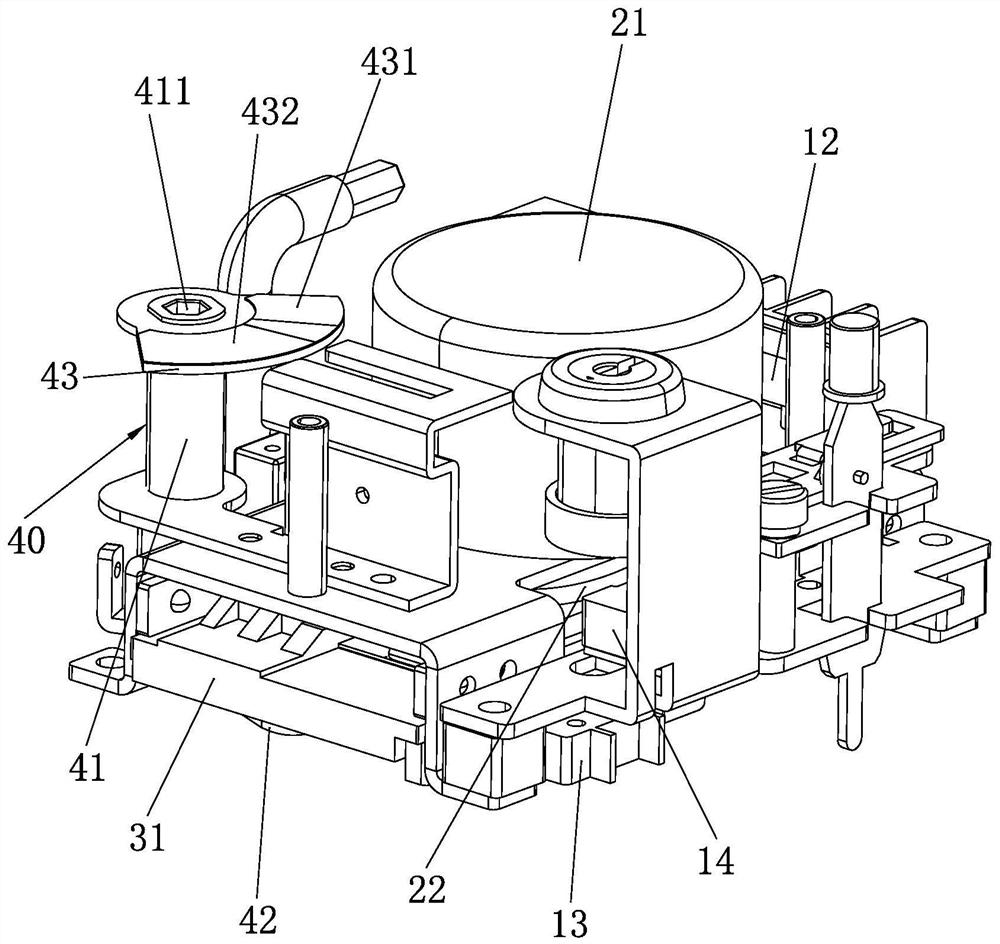

[0020] Such as Figure 1-7 As shown, the embodiment of the present invention is an electric operating mechanism, including a housing 10, a mechanism frame 11 arranged in the casing 10, an intelligent control circuit board 12 arranged on the mechanism frame 11, and a The electric drive assembly 20, the slider assembly 30 that is slidably arranged on the mechanism frame 11 and can drive the handle of the molded case circuit breaker to perform opening and closing, and the manual drive assembly 40 arranged on the mechanism frame 11, the electric drive assembly 20 It includes a motor 21 arranged on the mechanism frame 11, a cam 22 set in linkage with the motor 21, and the cam 22 is set in linkage with the output shaft 211 of the motor 21, and the slider assembly 30 includes a slider assembly 30 which is slidably arranged on the mechanism frame 11 and is connected with the The slider 31 that is coordinated with the cam 22, and the sleeve 32 that is set on the handle of the molded ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com