Transformer easy to produce and manufacture and manufacturing method thereof

A transformer and skeleton technology, applied in the field of transformers, can solve the problems of low production efficiency, small scope of application, troublesome operation, etc., and achieve the effects of improving production efficiency, wide application scope and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

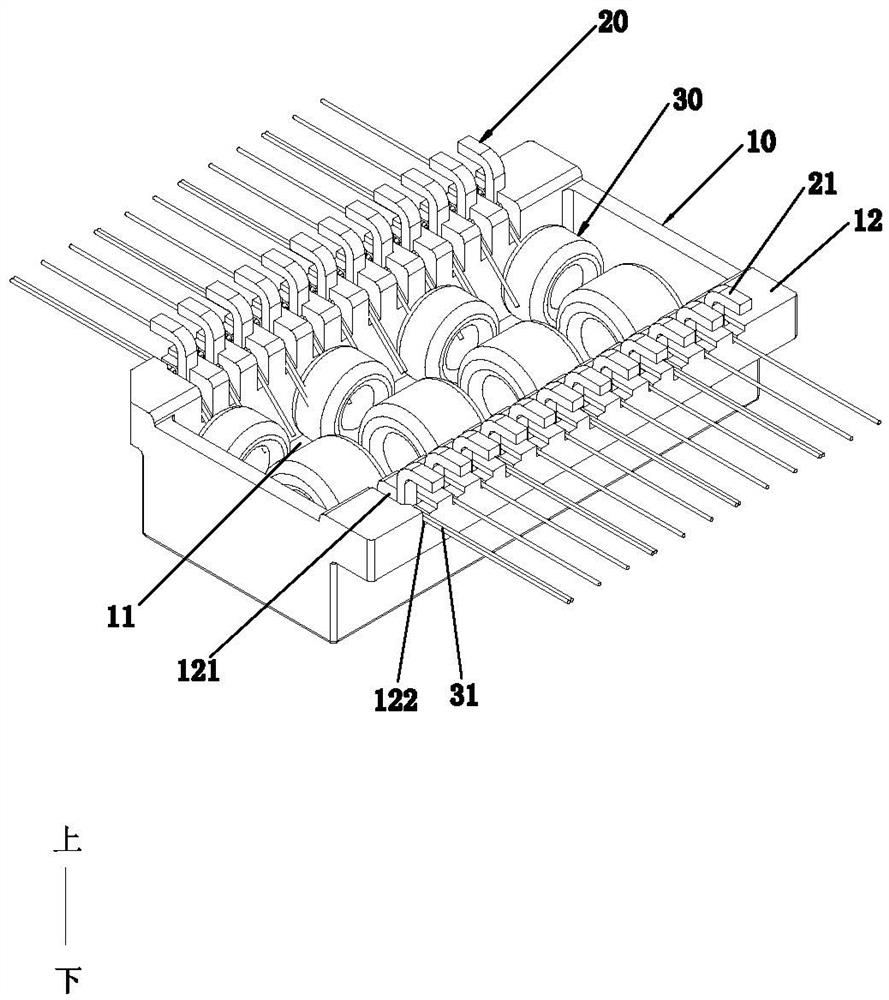

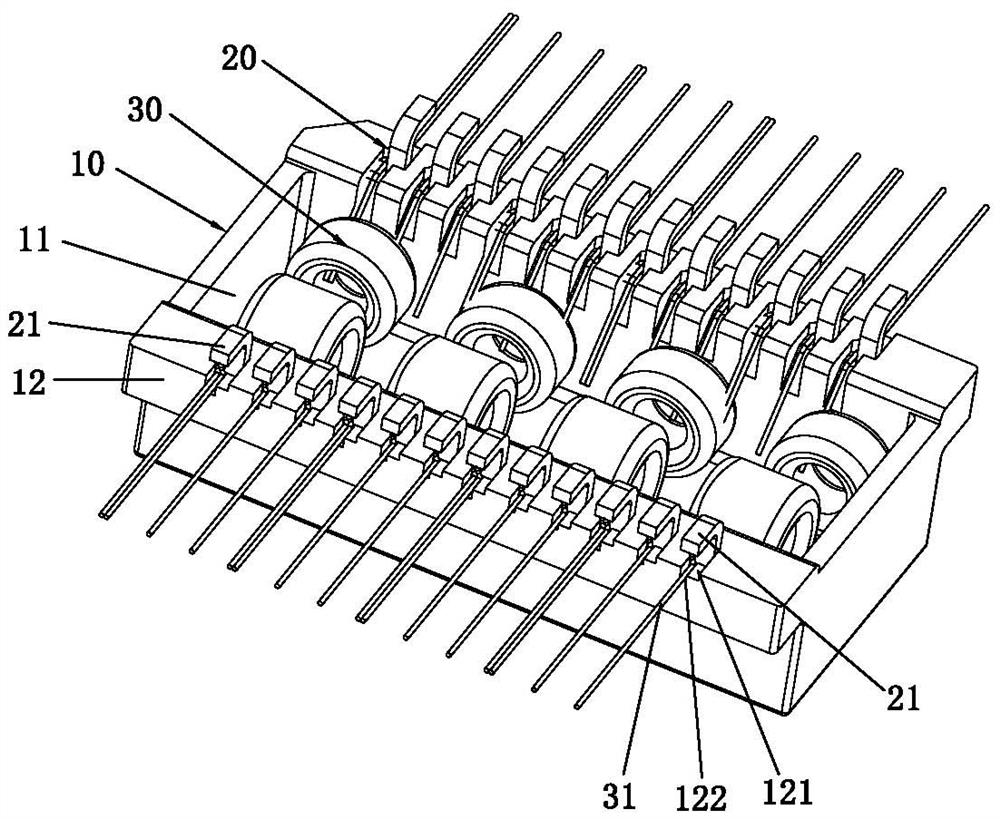

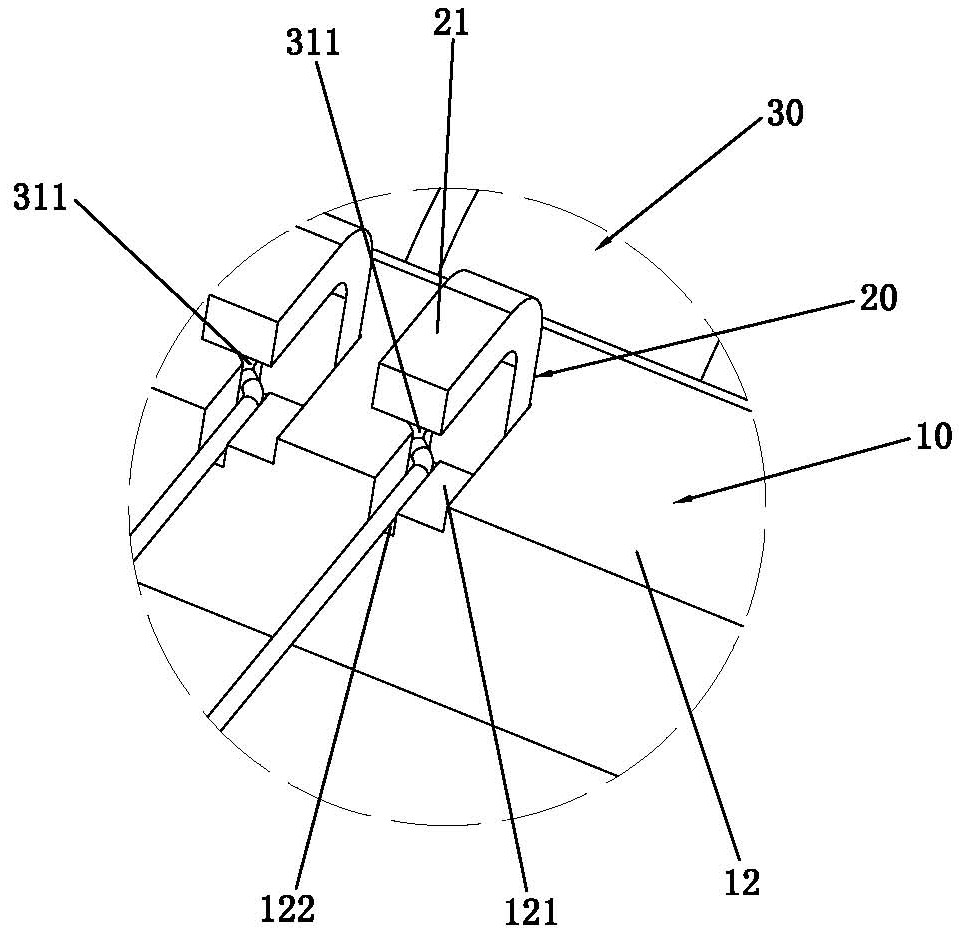

[0053] Please refer to Figures 1 to 16 As shown in the figure, it shows the specific structures of four embodiments of the present invention.

[0054] A transformer that is easy to manufacture includes a skeleton 10, pins 20 and a wound magnetic core 30; wherein:

[0055] The wound magnetic core 30 is arranged in the skeleton 10, the skeleton 10 is provided with a wire slot 122, the wound magnetic core 30 has an enameled wire 31, and the end of the enameled wire 31 is stretched into the wire slot 122 and Outward extension setting;

[0056] The upper end of the pin 20 is provided with a pressing part 21, and the pin 20 is installed on both sides of the skeleton 10 in a split type, and the pressing part 21 is pressed on the enameled wire 31 corresponding to the wire groove 122, so that The enameled wire 31 is clamped and positioned between the holding part 21 and the skeleton 10, and the holding part 21 and the enameled wire 31 are electrically connected and conducted; thus, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com