Large-current combined high-temperature inductor and processing method thereof

A processing method and combined technology, applied in the direction of transformer/inductor housing, transformer/inductor parts, inductor/transformer/magnet manufacturing, etc., can solve the problem that internal components are prone to jitter, increase the difficulty of device manufacturing, and inconvenient for automated production and other problems, to achieve the effect of low processing difficulty, improving processing efficiency and ensuring shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

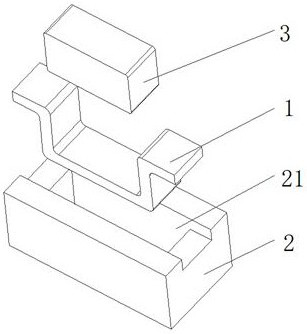

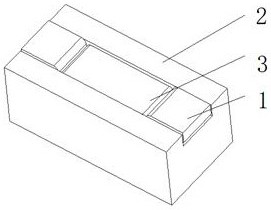

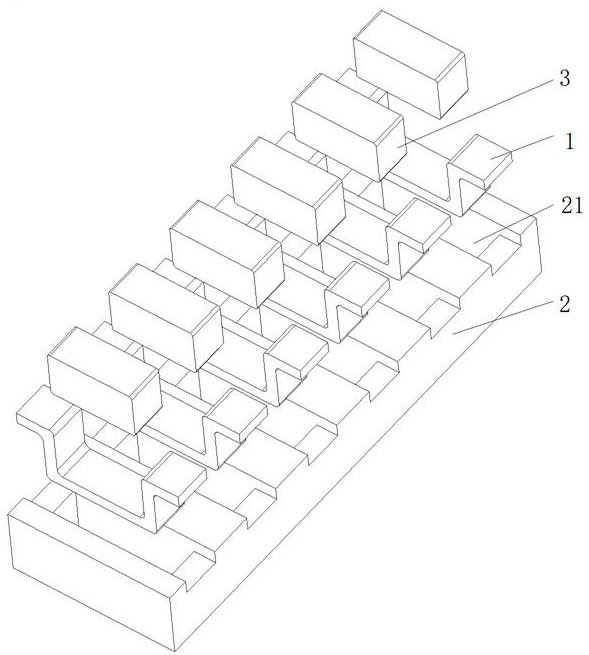

[0037] The present invention proposes a high-current combined high-temperature inductor and a processing method thereof, specifically as follows.

[0038] As shown in the figure, the present invention discloses a high-current combined high-temperature inductor, which is formed by bonding an induction magnet and an induction conductor 1. The induction magnet includes an external induction magnet 2 and at least one internal induction magnet 3. The external inductance magnet 2 is integrally formed, and at least one conductor storage groove 21 for setting the inductance conductor 1 is opened through the external inductance magnet 2, and each of the conductor storage grooves is provided with an inductance conductor 1 and the remaining space inside each of the inductance conductors 1 and the conductor receiving groove 21 is completely filled by a piece of the internal inductance magnet 3 .

[0039]The external induction magnet 2 is a cuboid structure as a whole, and the upper end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com