Cooling-water machine with dual-temperature double-control system structure

A system structure, chiller technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increasing the refrigeration load of the chiller, increasing the power of the whole machine, unsafe faults, etc. Large condensation area and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

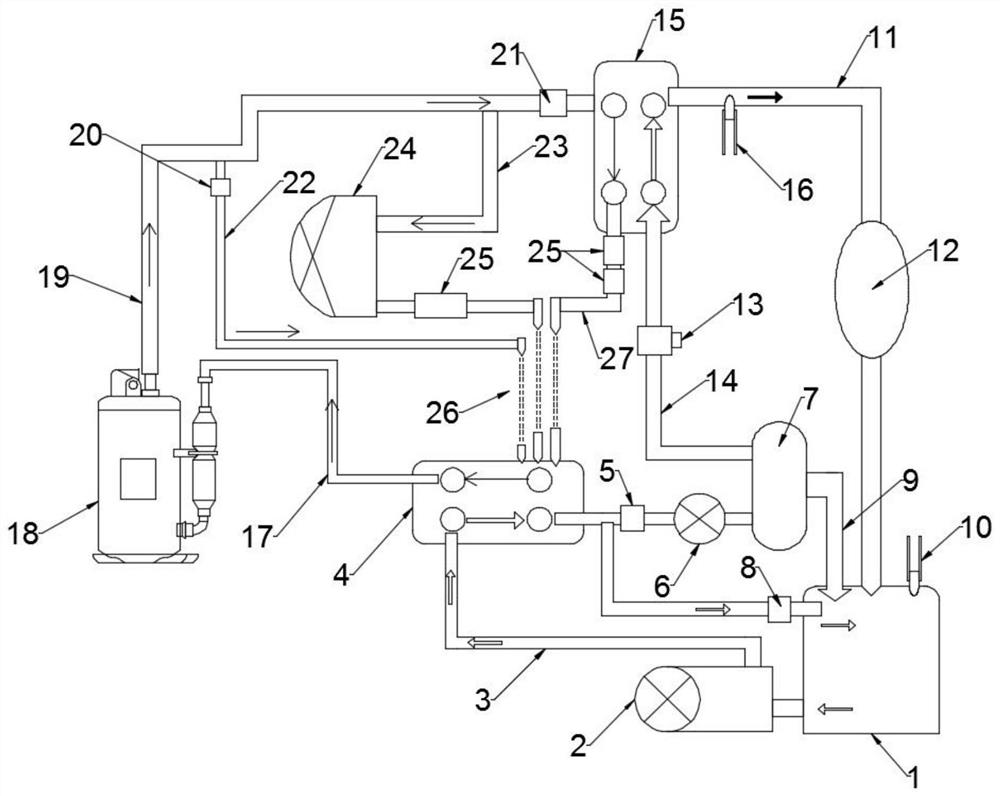

[0025] see figure 1 As shown, a chiller with a dual-temperature dual-control system structure includes a bucket 1, a cold-heat exchanger II4, a water storage 7, a cold-heat exchanger I15, a compressor 18, and a condenser 24. The compressor 18 The high-temperature gas outlet is connected to the high-pressure exhaust pipe 19, and the high-pressure exhaust pipe 19 is connected to the refrigerant input port of the cold-heat exchanger I15. The high-pressure exhaust pipe 19 at the refrigerant input port of the cold-heat exchanger I15 is equipped with a solenoid valve I21. The refrigerant output port of the cold heat exchanger I15 is connected to the air outlet pipe 27, and a filter 25 is installed on the air outlet pipe 27, and the air outlet pipe 27 is connected to the throttle valve 26, and the throttle valve 26 is connected to the refrigerant input port of the cold heat exchanger II4, The refrigerant output port of the cold heat exchanger II4 is connected to the air return port o...

Embodiment 2

[0036] The chiller with dual-temperature dual-control system structure as described in Example 1 includes a bucket 1, a cold heat exchanger II4, a water storage 7, a cold heat exchanger I15, a compressor 18, and a condenser 24. The high-temperature gas outlet of the machine 18 is connected to the high-pressure exhaust pipe 19, and the high-pressure exhaust pipe 19 is connected to the refrigerant input port of the cold heat exchanger I15, and the refrigerant output port of the cold heat exchanger I15 is connected to the air outlet pipe 27, and the air outlet pipe 27 is equipped with The filter 25 and the air outlet pipe 27 are connected to the throttle valve 26, and the throttle valve 26 is connected to the refrigerant input port of the cold heat exchanger II4, and the refrigerant output port of the cold heat exchanger II4 is connected to the air return port of the compressor 18 through the suction pipe 17.

[0037] The cold heat exchanger II4 is connected to the water pump 2 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com