Zirconium-loaded activated carbon high-activity material as well as preparation method and application thereof

A technology of activated carbon and high activity, applied in chemical instruments and methods, other chemical processes, sustainable biological treatment, etc., can solve the problems of complex preparation process, unstable performance, and further improvement of removal performance, and achieve strong removal ability , Improve the effect of removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of supported zirconium activated carbon, comprising the following steps:

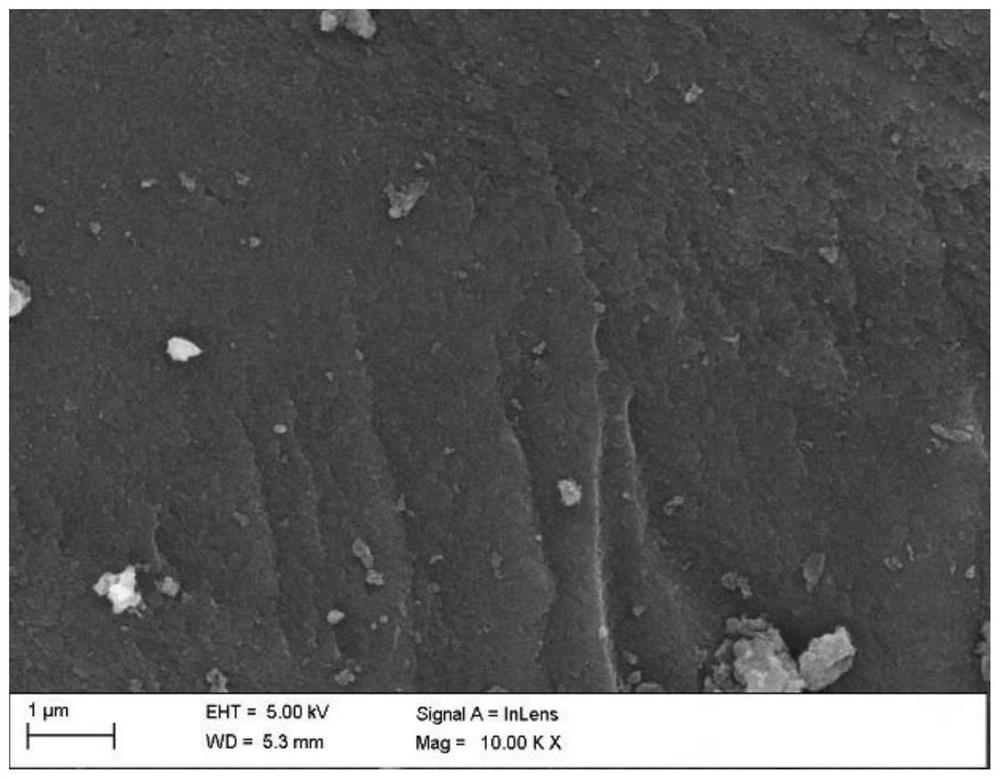

[0020] (1) Activated carbon pretreatment: soak 20-80 mesh activated carbon in 0.5mol / L NaOH solution for 24 hours, filter and rinse with deionized water until neutral, and dry at 70°C; then use 1.0mol / L Soak in hydrochloric acid solution for 24 hours, filter and rinse with deionized water until neutral, and then dry at 70°C.

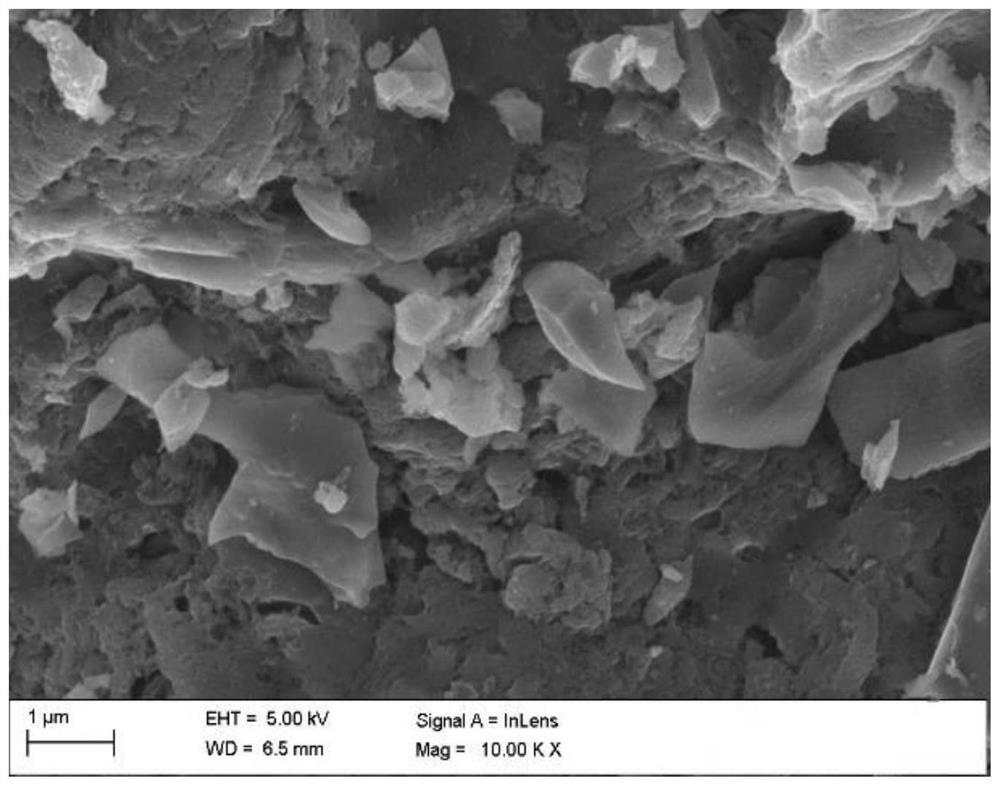

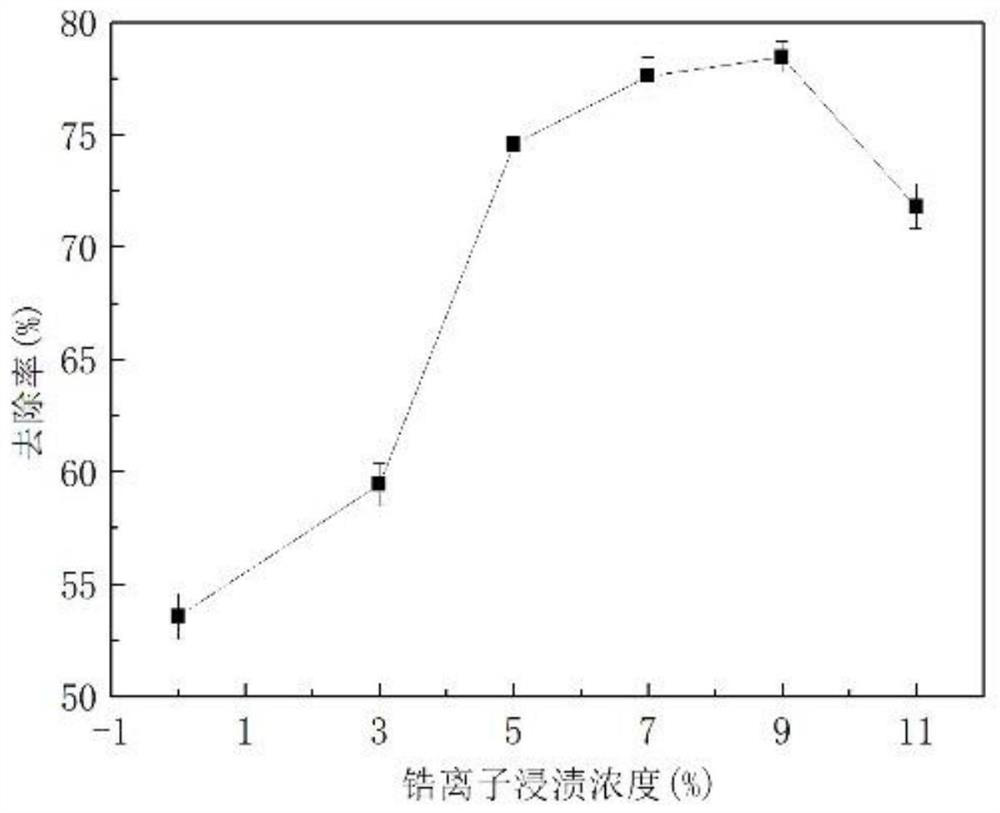

[0021] (2) Activated carbon loaded with zirconium: using the solution impregnation method, weigh 1 g of pretreated activated carbon and immerse it in solutions with a mass fraction of zirconium salt of 0% (unimpregnated), 3%, 5%, 7%, 9%, and 11%, respectively. , stirred at room temperature at 50 rpm for 9 hours, and then filtered the activated carbon and dried at 70°C to obtain zirconium-supported activated carbon.

[0022] (3) High temperature calcination: put the zirconium-supported activated carbon into the crucible, then use a muffle furnace for ca...

Embodiment 2

[0025] A preparation method of supported zirconium activated carbon, comprising the following steps:

[0026] (1) Activated carbon pretreatment: soak 20-80 mesh activated carbon in 0.5mol / L NaOH solution for 24 hours, filter and rinse with deionized water until neutral, and dry at 90°C; then use 1.0mol / L The hydrochloric acid solution was soaked for 24 hours, filtered and rinsed with deionized water until neutral, and then dried at 90°C.

[0027] (2) Activated carbon supported zirconium: using the solution impregnation method, weigh 1 g of pretreated activated carbon and immerse it in a solution with a mass fraction of 7% zirconium salt, stir at room temperature for 9 hours at a speed of 80 rpm, and then filter the activated carbon and heat it at 90 °C drying under conditions to obtain zirconium-supported activated carbon. .

[0028] (3) High-temperature calcination: The zirconium-supported activated carbon is put into a crucible, then calcined in a muffle furnace at 500° C....

Embodiment 3

[0031] A preparation method of supported zirconium activated carbon, comprising the following steps:

[0032] (1) Activated carbon pretreatment: soak 20-80 mesh activated carbon in 0.5mol / L NaOH solution for 24 hours, filter and rinse with deionized water until neutral, and dry at 80°C; then use 1.0mol / L The hydrochloric acid solution was soaked for 24 hours, filtered and rinsed with deionized water until neutral, and then dried at 80°C.

[0033] (2) Activated carbon supported zirconium: Using the solution impregnation method, 1 g of pretreated activated carbon was weighed and immersed in a solution with a mass fraction of 9% zirconium salt, stirred at room temperature for 7 hours at a speed of 80 rpm, and then the activated carbon was filtered and heated at 80 ° C. drying under conditions to obtain zirconium-supported activated carbon. .

[0034] (3) High-temperature calcination: The zirconium-supported activated carbon was put into a crucible, then calcined at 400° C. for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com