Conveying device capable of screening square plates

A technology for conveying devices and plates, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as no processing function, and achieve the effects of controllable work, simple overall structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

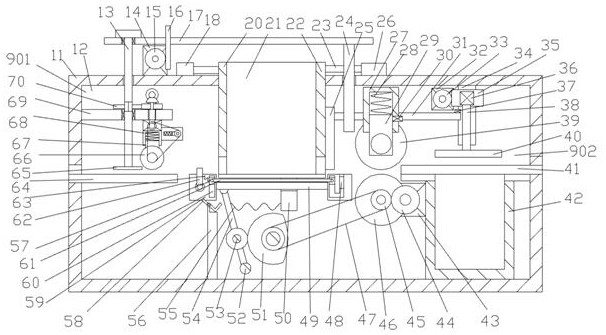

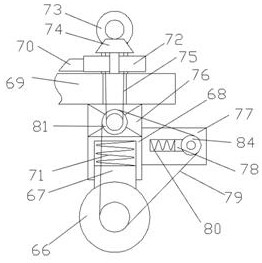

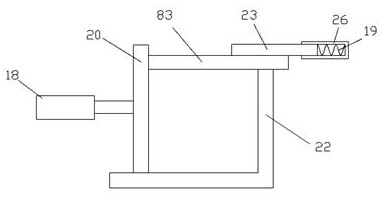

[0014] Combine below Figure 1-Figure 4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0015] The present invention relates to a conveying device for screening processing of square plates, which is mainly used in the process of screening and transporting square plates. The present invention will be further described below in conjunction with the drawings of the present invention: a screening process of square plates according to the present invention The conveying device includes a box body 11, a motor 14 is fixed on the upper side of the box body 11, a gear 15 is connected to the motor 14 in rotation, a rack 16 is slidably connected to the right side of the gear 15, and the rack 16 is fixed There is a transverse axis 17 extending to both sides, and a cavity 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com