A joint structure on a d-pillar

A technology of joint structure and joint connection, which is applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., which can solve the problems of many processes, long mold debugging time, high precision requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

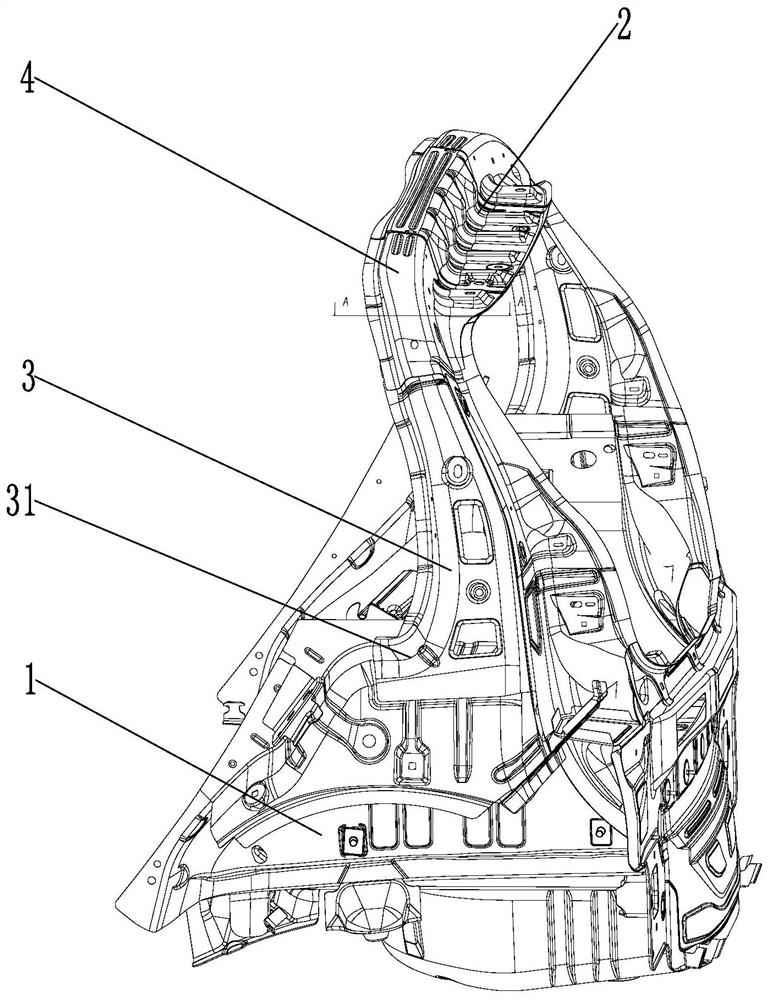

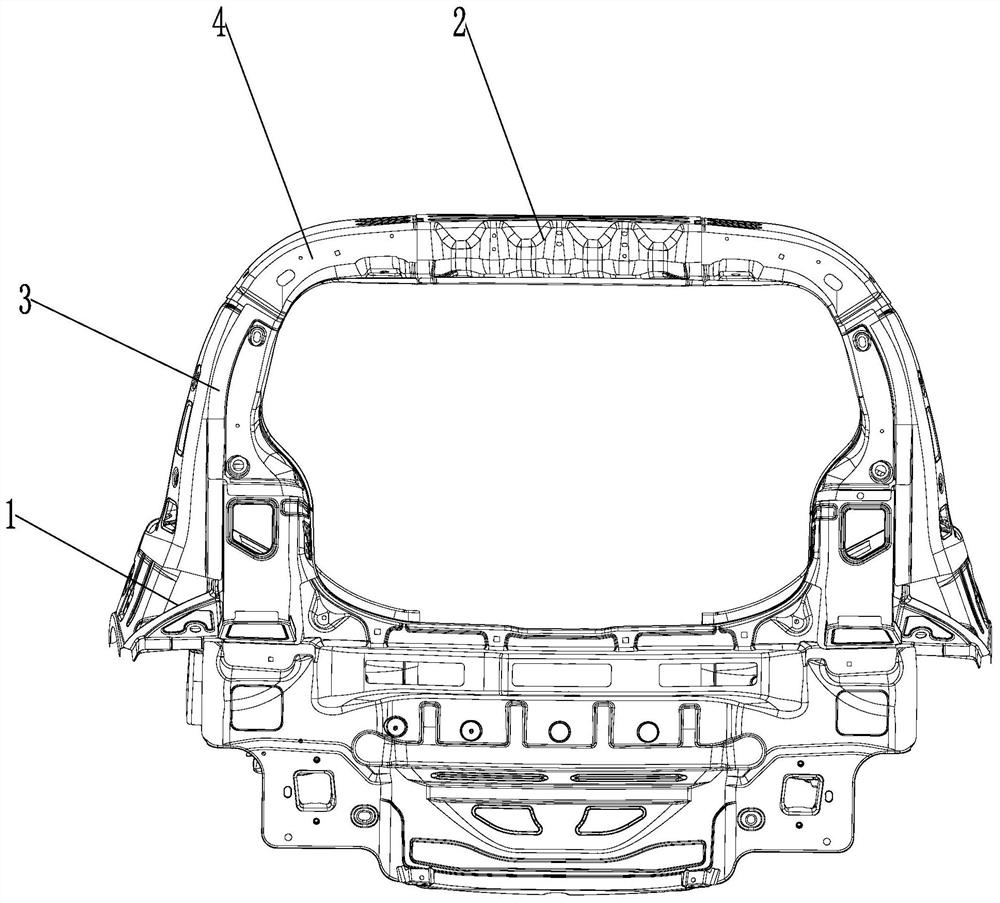

[0025] Embodiment 1: as figure 1 and image 3 as shown in

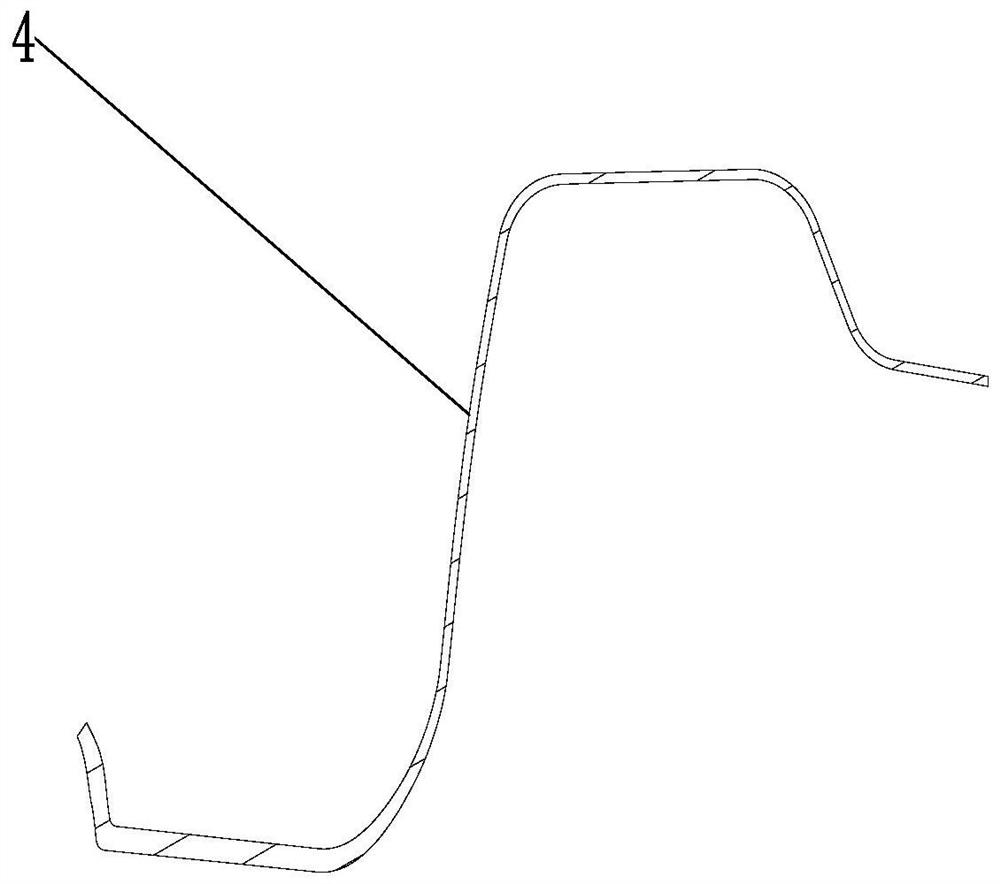

[0026] A D-pillar upper joint structure, including an outer wheel house 1, a rear roof beam 2, and a D-pillar reinforcement plate 3 arranged on a D-pillar 9. The D-pillar reinforcement plate is located at the left and right ends of the rear roof beam, and the upper and lower sides of the D-pillar reinforcement plate are The two ends are respectively connected with the rear roof beam and the outer wheel house. The upper end of the D-pillar reinforcement plate is connected with the rear roof beam through the D-pillar upper joint 4. There are two joints 41 on the D-pillar upper joint, one of which is connected to the rear roof beam, and the other One joint attaches to the D-pillar reinforcement. The present invention improves the joint structure on the D-pillar, adopts the two-joint structure, and greatly reduces the difficulty of stamping compared with the three-joint structure, greatly improves the precision and redu...

Embodiment 2

[0028] Embodiment 2: Based on the structure of the above-mentioned embodiment, such as Figure 4 as shown,

[0029] There is a buffer structure between the D-pillar upper joint and the D-pillar, and the buffer structure includes the airbag 5 on the D-pillar. The joints are used to cushion the connections at the joints. The buffer structure is conducive to the installation of the joints on the D-pillar. While ensuring sufficient torsional rigidity of the joints on the D-pillar, it can also prevent stress concentration. In addition, in the event of an unexpected collision, the buffer structure can provide force relief. The upper joint has a protective effect.

[0030]The D-pillar is provided with an air chamber, the airbag is located in the air chamber, the airbag is located below the joint, the air chamber is provided with an extruding plate 6 slidingly arranged, and the lower end of the joint on the D-pillar is provided with a downwardly protruding fixing plate 7, the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com