Paint room with paint spraying waste gas treatment system

A technology for waste gas treatment and paint room, applied in the field of paint room, can solve the problems affecting the physical and mental health of surrounding construction workers, the escape of waste gas, and environmental pollution, so as to avoid open-air paint spraying, reduce the probability of fire accidents, and avoid environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

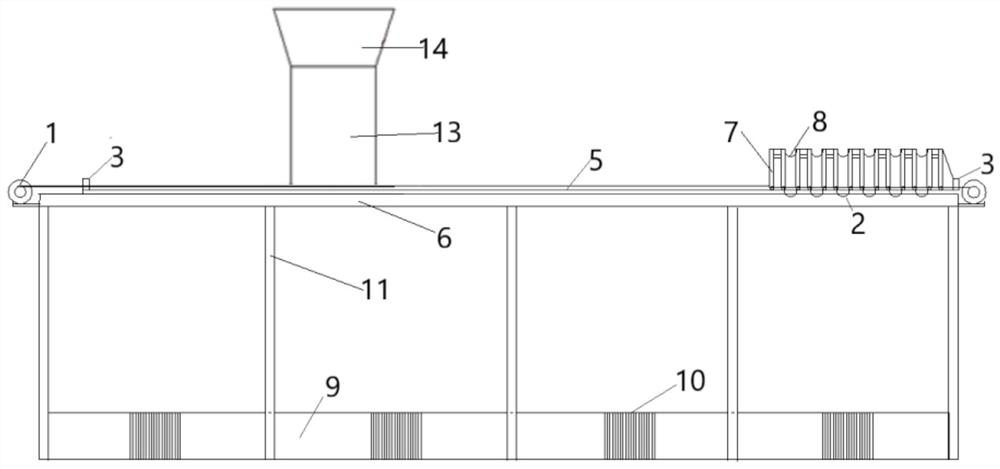

[0023] The paint room with paint spraying exhaust gas treatment system shown in the figure includes a room body 12 for paint spraying, a centrifugal fan 21 and an exhaust gas treatment system 15. The room body 12 passes the paint exhaust gas into the exhaust gas treatment system 15 through the centrifugal fan 21 , the waste gas treatment system 15 includes a waste gas inlet 16, a waste gas treatment box and a gas discharge channel, the house body 12 includes a ceiling that can be opened and closed, and the ceiling includes two H-shaped steels 6 and several groups of trusses 7 arranged in parallel, and the H-shaped steels 6 are provided with The I-shaped steel guide rail 5 in the same direction as it, several groups of trusses 7 are vertically arranged with the H-shaped steel 6 and are provided with rollers 4 that can slide along the I-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com