Preparation method of stannic oxide/polyaniline nanowire composite photocatalyst

A technology of tin dioxide and polyaniline, which is applied in the field of material chemistry, can solve the problems of difficult control of the synthesis process of tin dioxide, difficult control of shape, and influence on the enhancement effect, so as to achieve easy control of reaction, simple equipment, and high material utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

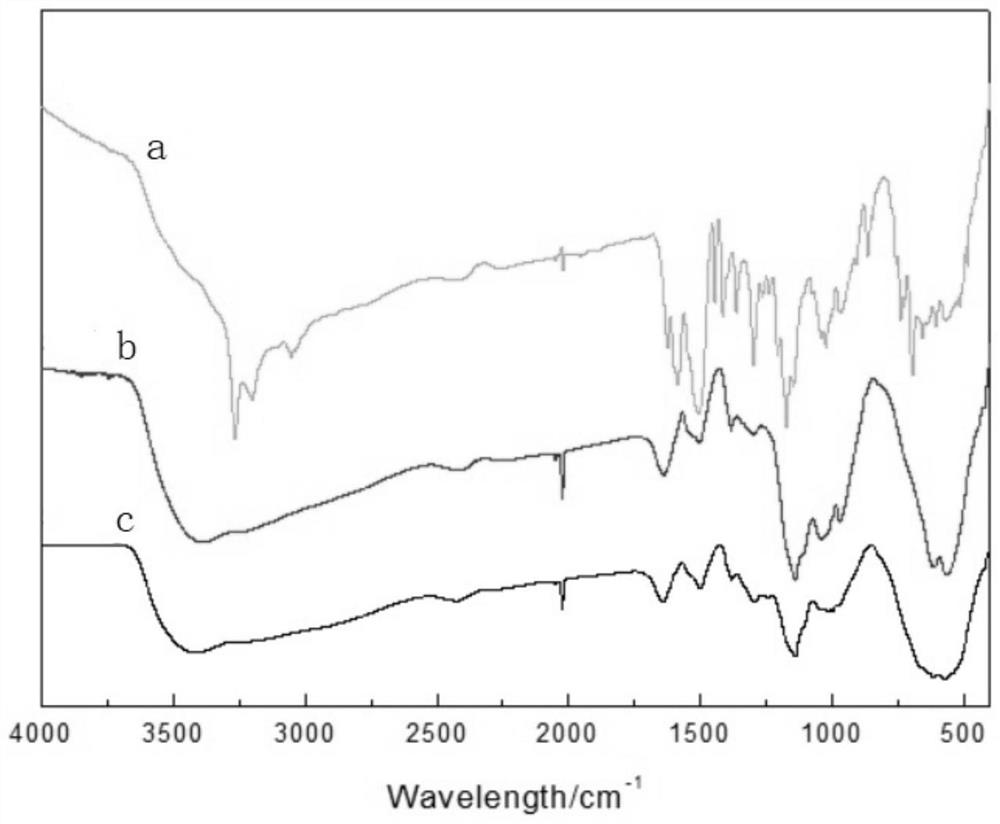

[0033] The preparation method of tin dioxide / polyaniline composite photocatalyst, concrete steps are as follows:

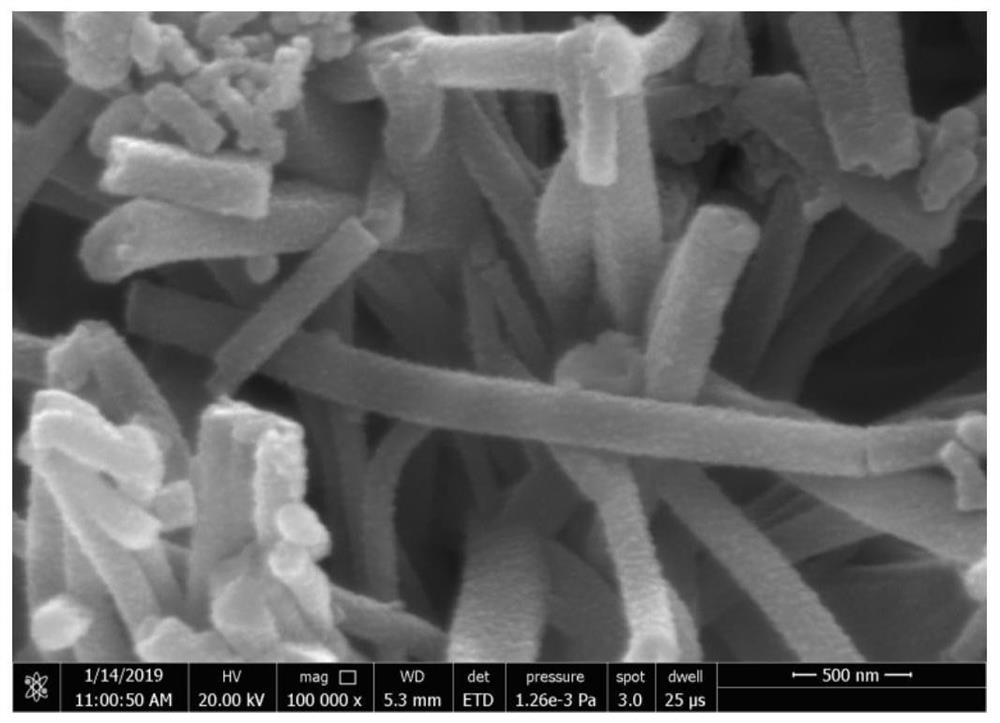

[0034] Preparation of polyaniline nanowires

[0035] First add 25mg of aniline and phosphoric acid solution in a 200ml beaker and mix. After stirring in an ice-water bath, add ammonium sulfate and continue stirring until it is dark green. The stirred solution was frozen in the refrigerator and removed after 15 hours. The solution was centrifuged, and the precipitate was washed several times with deionized water and dried in an oven at 60 °C.

[0036] Preparation of tin dioxide / polyaniline composite photocatalyst:

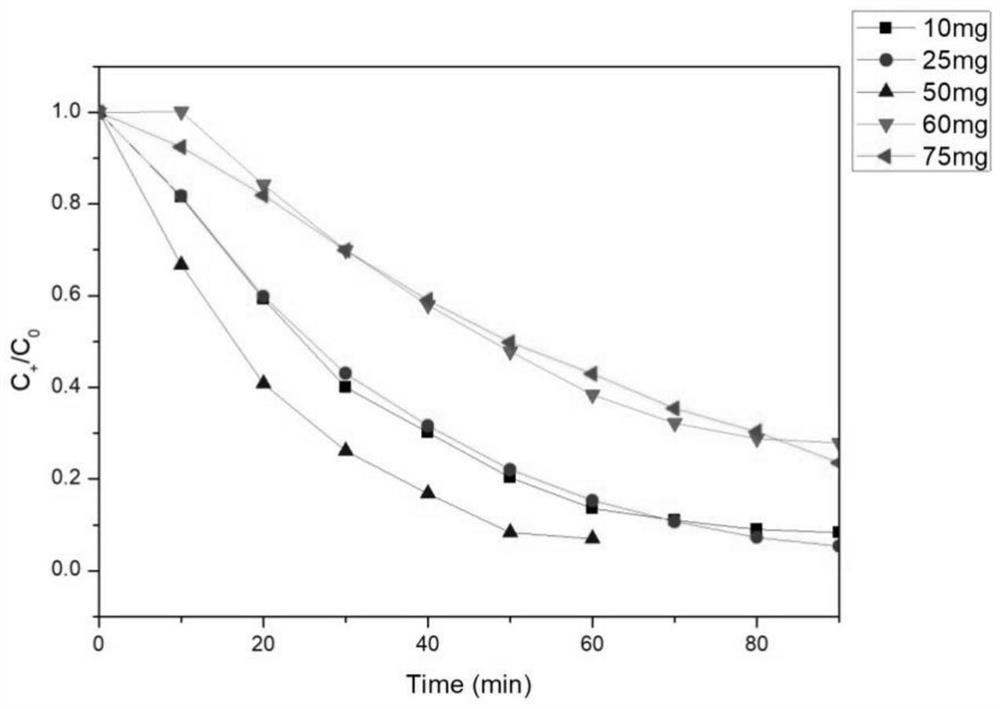

[0037] Dissolve stannous sulfate powder in sulfuric acid solution as a precursor solution, and pour it into a reaction vessel as a precursor solution. Sprinkle 0.05g polyaniline powder on the precursor liquid, carry out photochemical synthesis under the irradiation of 8W ultraviolet lamp, and turn off the ultraviolet lamp after 24 hours. Take out a...

Embodiment 2

[0039] The preparation of tin dioxide / polyaniline composite photocatalyst, concrete steps are as follows:

[0040] Preparation of polyaniline powder:

[0041] First add 25mg of aniline and phosphoric acid solution in a 200ml beaker and mix. After stirring in an ice-water bath, add ammonium sulfate and continue stirring until it is dark green. The stirred solution was placed in the refrigerator to freeze and removed after 24 hours. The solution was centrifuged, and the precipitate was washed several times with deionized water and dried in an oven at 60 °C.

[0042] Preparation of tin dioxide / polyaniline composite photocatalyst:

[0043] Dissolve stannous sulfate powder in sulfuric acid solution as a precursor solution, and pour it into a reaction vessel as a precursor solution. Sprinkle 0.05g polyaniline powder on the precursor liquid, carry out photochemical synthesis under the irradiation of 8W ultraviolet lamp, and turn off the ultraviolet lamp after 24 hours. Take out ...

Embodiment 3

[0045] The preparation of tin dioxide / polyaniline composite photocatalyst, concrete steps are as follows:

[0046] Preparation of polyaniline powder:

[0047] First add 25mg of aniline and phosphoric acid solution in a 200ml beaker and mix. After stirring in an ice-water bath, add ammonium sulfate and continue stirring until it is dark green. The stirred solution was frozen in the refrigerator and removed after 36 hours. The solution was centrifuged, and the precipitate was washed several times with deionized water and dried in an oven at 60 °C.

[0048] Preparation of tin dioxide / polyaniline composite photocatalyst:

[0049]Dissolve stannous sulfate powder in sulfuric acid solution as a precursor solution, and pour it into a reaction vessel as a precursor solution. Sprinkle 0.05g polyaniline powder on the precursor liquid, carry out photochemical synthesis under the irradiation of 8W ultraviolet lamp, and turn off the ultraviolet lamp after 24 hours. Take out and centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com