Steel structure coating anti-corrosion performance evaluation method and system, server and storage medium

A coating anti-corrosion and steel structure technology, applied to instruments, character and pattern recognition, color/spectral characteristic measurement, etc., can solve the problems of inability to evaluate performance grades, low efficiency, and inability to obtain evaluation results in real time, and achieve fast and accurate grades Evaluate and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

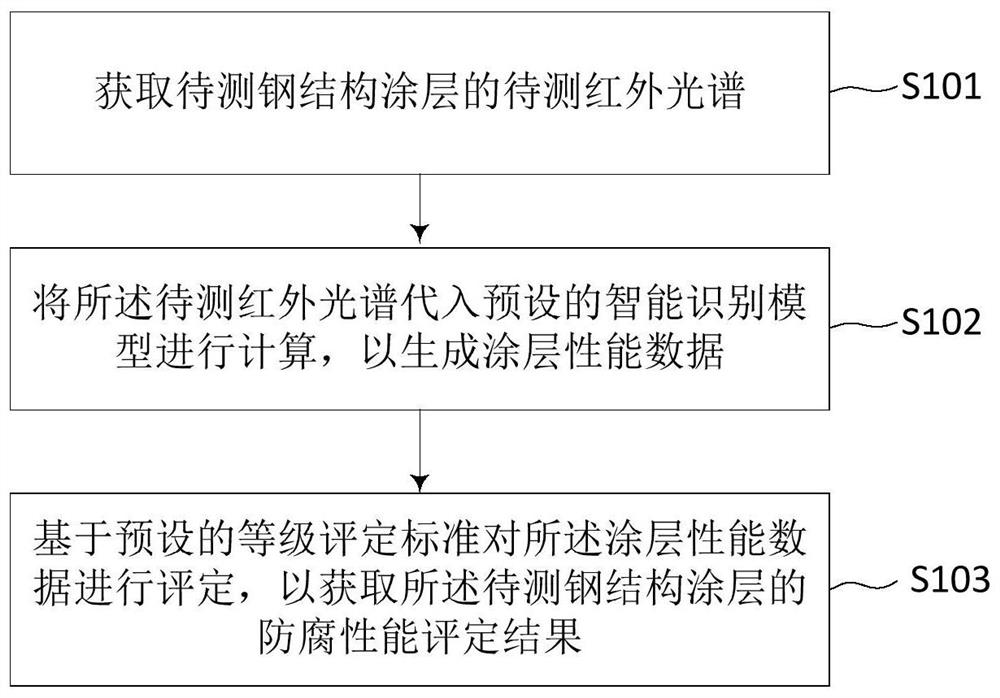

[0052] Such as figure 1 As shown, this embodiment provides a method for evaluating the anticorrosion performance of steel structure coatings. The steel structure coating performance detection system is used as the execution subject, and the output results are evaluated for the anticorrosion performance of steel structure coatings by bringing in the model calculation. Proceed as follows:

[0053] S101. Obtain the infrared spectrum of the steel structure coating to be tested.

[0054] The infrared spectrum to be measured described in this step is usually divided into three regions in practical applications: the near infrared region (0.75-2.5 μm), the mid-infrared region (2.5-25 μm) and the far-infrared region (25-25 μm). 300μm). The near-infrared spectrum is generated by frequency doubling and combining of molecules. Preferably, the infrared spectrum in this embodiment and the following embodiments is detected by near-infrared light, which has the advantages of low equipment c...

Embodiment 2

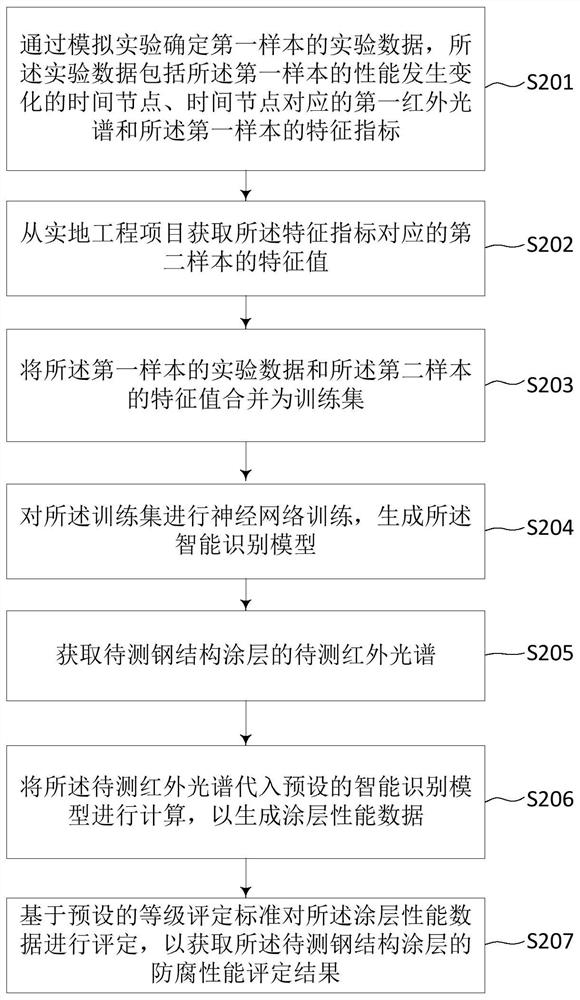

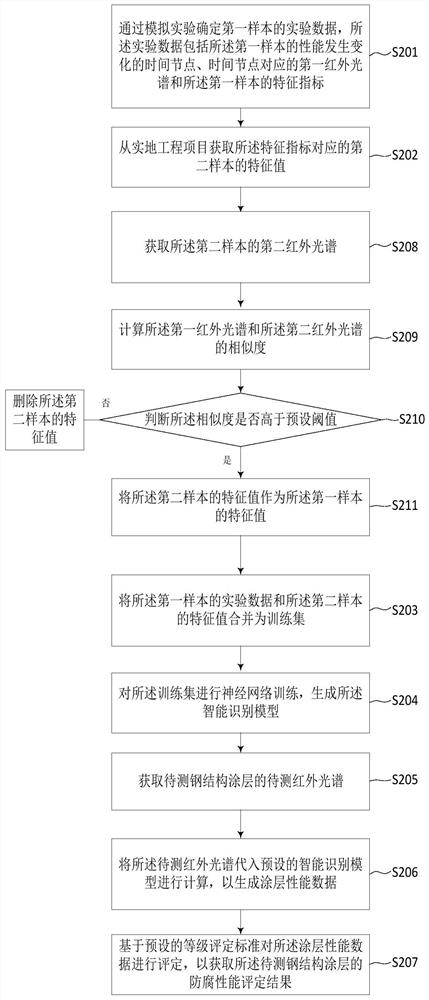

[0061] Such as figure 2 As shown, this embodiment increases the training process of the intelligent recognition model on the basis of the above embodiments, including:

[0062] S201. Determine the experimental data of the first sample through a simulation experiment, the experimental data includes the time node when the performance of the first sample changes, the first infrared spectrum corresponding to the time node, and the characteristics of the first sample index.

[0063] This step adopts the method of indoor simulation experiment. The first sample refers to the sample steel structure coating used in the indoor simulation experiment, and the first infrared spectrum refers to the data of the spectrum experiment of the first sample during the durability experiment process.

[0064] In one embodiment, the simulation experiment includes a durability experiment, a microscopic experiment, an electrochemical experiment and / or a spectroscopic experiment. Correspondingly, the ...

Embodiment 3

[0092] Such as Figure 4 , this embodiment increases the image processing of the infrared spectral image before the model calculation on the basis of the above-mentioned embodiment, through the image processing, the image characteristics of the spectral image are enhanced, the contrast is improved, the model calculation can remove the interference image, and the calculation accuracy is improved. Rate. The steps are:

[0093] S3011. Obtain a coating image of the steel structure coating to be tested.

[0094] The coating image in this step refers to the actual image of the steel structure layer to be tested.

[0095] S3012. Perform HSV color space image processing on the coating image, so as to remove non-corroded areas in the coating image and retain rusted areas.

[0096] In this embodiment, the coating image is subjected to HSV color space conversion, and the coating image area that satisfies the preset HSV color range is obtained as the rust area, and the obtained coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com