Device for detecting performance of all-aluminum light-weight container plate

A lightweight, container board technology, applied in the field of performance testing devices for all-aluminum lightweight container boards, can solve problems such as insufficient waterproofing and leakage detection, uneven stress, and inconvenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

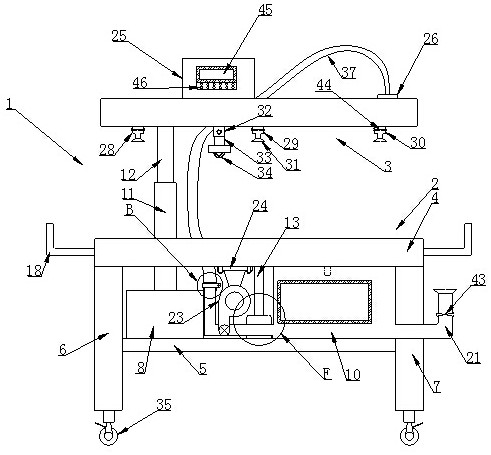

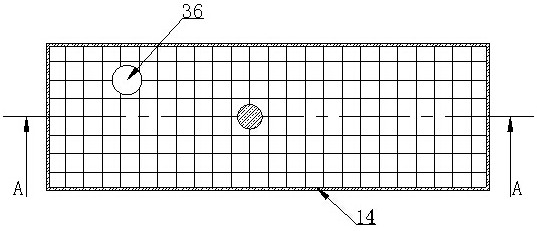

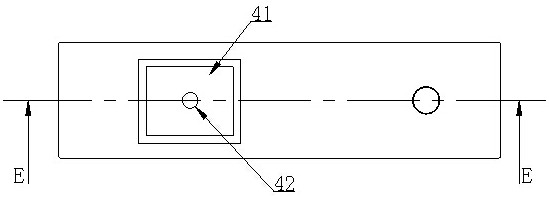

[0035] like Figure 1 to Figure 9 The device for testing the performance of this all-aluminum lightweight container board of the present invention includes a device body 1, and the device body 1 includes a lower frame body 2 and an upper work surface 3, and a lower frame body 2 and an upper work surface 3. The integrated design makes the detection efficiency of the all-aluminum lightweight container board higher. The lower shelf body 2 includes a horizontal support table 1 4, a support leg and a horizontal partition 1 5, and the support leg is provided with a support leg 6 and a support leg 2 7. Horizontal partition one 5 is provided with hydraulic expansion cylinder one 8, hydraulic expansion cylinder two 9 and water tank one 10, hydraulic expansion cylinder one 8 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com