A thermoplastic resin product laying device

A thermoplastic resin and laying device technology, applied in the field of thermoplastic resin, can solve the problems of poor fluidity of marking paint, reduce work efficiency of workers, increase labor workload of workers, etc., reduce frequency, avoid fatigue caused by repeated bending, reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

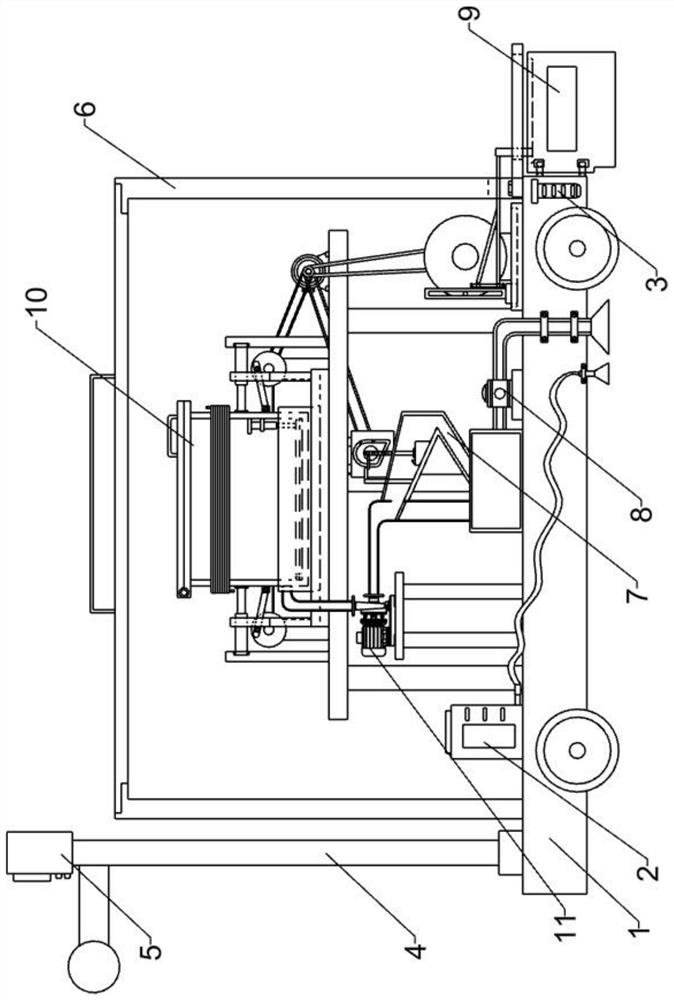

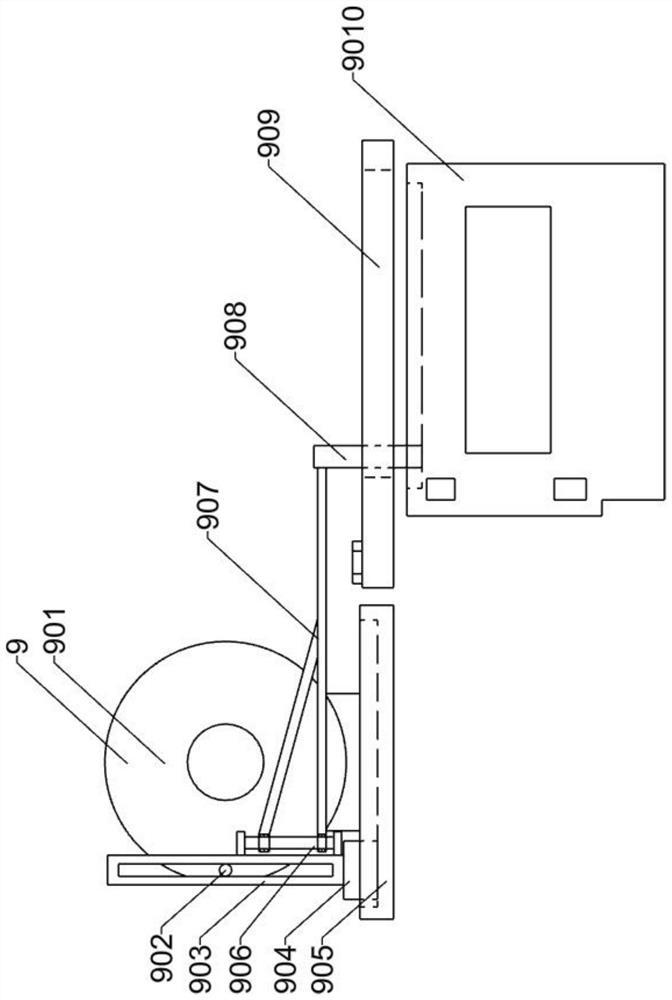

[0025] A thermoplastic resin product laying device, such as Figure 1-6 As shown, it includes a vehicle bottom 1, an air-conditioning tank 2, a camera 3, a push handle 4, a control panel 5, a casing 6, a crushing device 7, a supercharger 8, a road surface cleaning device 9, an anti-condensation device 10 and a liquid pump 11 The left side of the top middle part of the bottom 1 is provided with an air-conditioning tank 2; the front right side of the bottom 1 is bolted to the camera 3; the top left side of the bottom 1 is bolted to the push handle 4; the top of the bottom 1 is connected to the shell 6 The bolts are connected, and the cold air tank 2 is located on the left side of the middle part of the inner bottom of the shell 6, and the push handle 4 is located on the left side of the shell 6; the top middle of the bottom 1 is provided with a crushing device 7; The cleaning device 9 is connected; the front side of the top of the push handle 4 is provided with a control panel 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com