Stable long-acting compound fertilizer and preparation method thereof

A compound fertilizer and stability technology, applied in the direction of phosphate fertilizer, fertilization device, fertilizer mixture, etc., can solve the problems that affect the environmental quality and sustainable economic development, rarely meet the biodegradation standard, and the heavy metal content exceeds, etc., to reduce soil Effects of hardening and environmental pollution, enhancing crop stress resistance, and moderate chelation constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

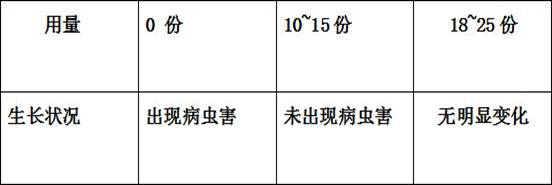

Examples

Embodiment 1

[0037] A stable long-acting compound fertilizer, the compound fertilizer comprises the following components by weight: 50 parts of coated urea, 10 parts of superphosphate, 5 parts of ammonium chloride, 7 parts of potassium chloride, 10 parts of sweet potato type citric acid residue 6 parts of distiller's grains, 3 parts of EDTA chelated zinc, 4 parts of amino acid chelated iron, 10 parts of diethyl hexanoate, 5 parts of urease inhibitor, and 6 parts of kaolin.

[0038] A kind of preparation method of stable long-acting compound fertilizer, is characterized in that, comprises the following steps,

[0039] (1) Grind the sweet potato dregs and distiller's grains separately, pass through a 60-mesh sieve, mix well, and ferment at 25°C for 6 days, stirring once a day in the morning and evening, each stirring time is 18 minutes, and the stirring rate is 42 rpm to obtain material 1 ;

[0040] (2) Mix polyvinyl alcohol and polyurethane, then add it to an organic solvent, stir continuo...

Embodiment 2

[0044] A stable long-acting compound fertilizer, the compound fertilizer comprising the following components by weight: 130 parts of coated urea, 25 parts of superphosphate, 20 parts of ammonium chloride, 25 parts of potassium chloride, 30 parts of sweet potato type citric acid slag 30 parts of distiller's grains, 18 parts of EDTA chelated zinc, 20 parts of amino acid chelated iron, 25 parts of forchlorfenuron, 18 parts of urease inhibitor, 28 parts of talcum powder.

[0045] A kind of preparation method of stable long-acting compound fertilizer, is characterized in that, comprises the following steps,

[0046](1) Separately pulverize sweet potato dregs and distiller's grains, pass through a 80-mesh sieve, mix evenly, and ferment at 35°C for 12 days, stirring once a day in the morning and evening, each stirring time is 35 minutes, and the stirring rate is 85 rpm to obtain material 1 ;

[0047] (2) Mix polyvinyl alcohol and polyurethane, then add it to an organic solvent, stir...

Embodiment 3

[0051] A stable long-acting compound fertilizer, the compound fertilizer comprising the following components by weight: 60 parts of coated urea, 12 parts of superphosphate, 7 parts of ammonium chloride, 9 parts of potassium chloride, 12 parts of sweet potato type citric acid residue 7 parts of distiller's grains, 4 parts of EDTA chelated zinc, 5 parts of amino acid chelated iron, 12 parts of sodium naphthalene acetate, 6 parts of urease inhibitor, 7 parts of sodium dodecylbenzenesulfonate.

[0052] A kind of preparation method of stable long-acting compound fertilizer, is characterized in that, comprises the following steps,

[0053] (1) Separately pulverize the sweet potato dregs and distiller's grains, pass through a 62-mesh sieve, mix evenly, and ferment at 28°C for 7 days, stirring once every morning and evening, each stirring time is 19 minutes, and the stirring rate is 45 rpm to obtain material 1 ;

[0054] (2) Mix polyvinyl alcohol and polyurethane, then add it to an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com