Sewage and sludge separation and cyclic utilization equipment for constructional engineering

A technology of sewage sludge and construction engineering, applied in the direction of water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient diffusion and mixing of flocculants and sewage, and inability to accurately stir sewage and other problems, to achieve the effect of reducing the frequency of manual cleaning of the filter screen, better separation and use performance, and ingenious and reasonable linkage structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

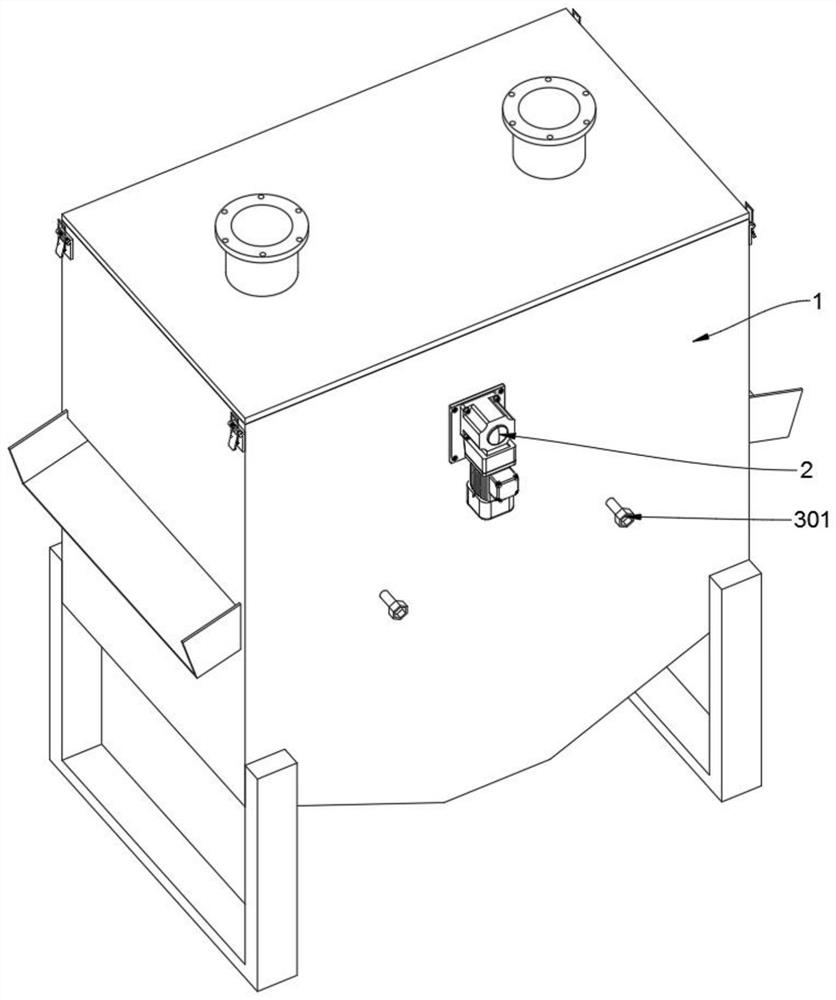

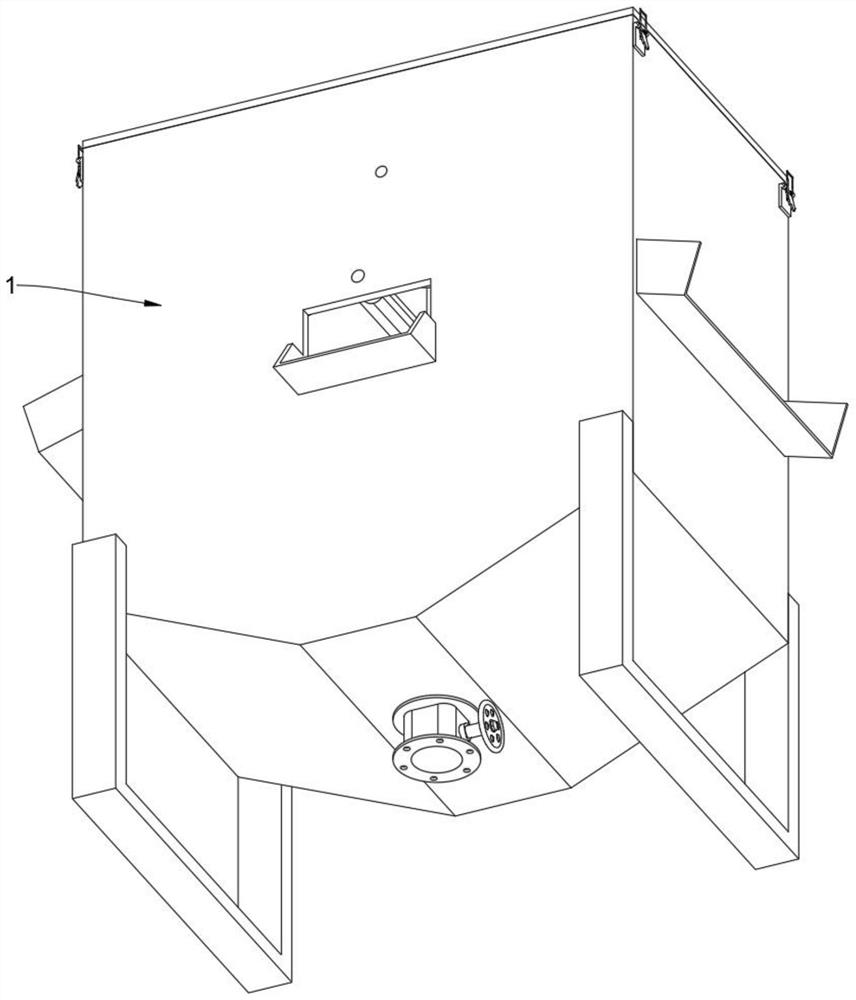

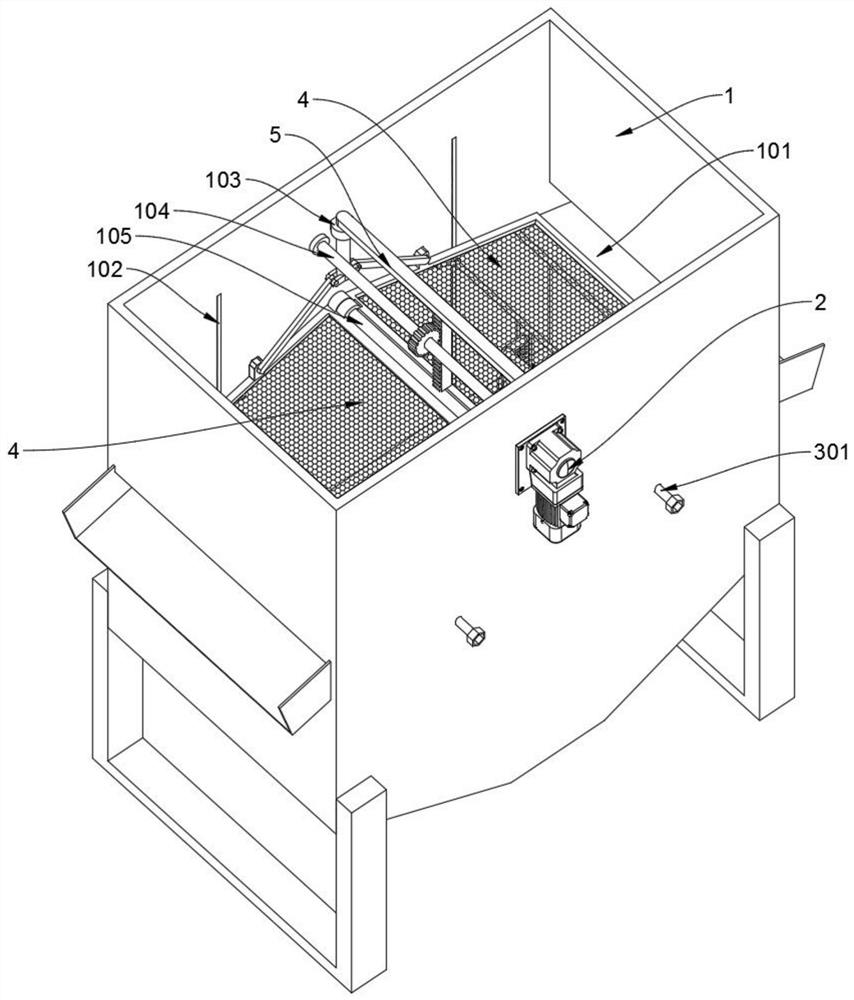

[0029] see Figure 1 to Figure 9 , an embodiment provided by the present invention: a sewage sludge separation and recycling equipment for construction engineering, including a sewage tank 1, the sewage tank 1 includes a track groove 102, a positioning ring 103, a transmission shaft 104 and a positioning shaft 105, The sewage tank 1 has a rectangular structure as a whole, and a cover plate is tightened and fixed on the top opening, and two water inlet pipes are welded with symmetrical vertical supports on the cover plate; To the track groove 102, and the top middle position of the front and rear inner walls of the waste water tank 1 is installed with a transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com