Constructional engineering building material hoisting device

A lifting device and construction engineering technology, which is applied in the direction of transportation and packaging, load hanging components, springs/shock absorbers, etc., can solve the problems of danger, unusability, and safety hazards in the lifting process, and improve the flexibility of use , use better, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

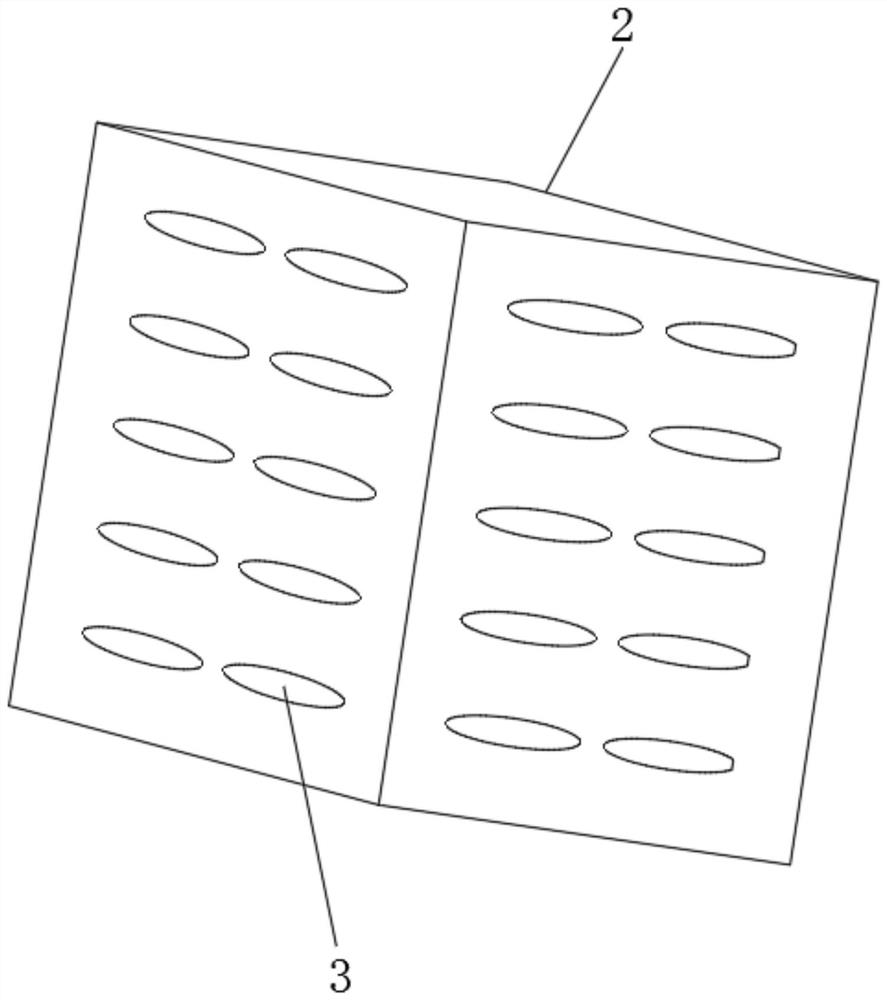

[0029] refer to Figure 1-4 , a construction material lifting device, comprising a lifting box 1 and a lifting part 16, the inner rotation of the lifting part 16 is provided with a turntable 17, the bottom outer wall of the turntable 17 is fixedly connected with a movable column 19, and the movable column 19 The outer wall of the bottom is fixedly connected with lifting rings 20, and the four corners of the top outer wall of the lifting box 1 are fixedly connected with fixing rings 7, and the fixing rings 7 and the lifting rings 20 are bolted by wire ropes 8, and the lifting box 1 is provided with a limit mechanism.

[0030] The outer wall of the bottom of the turntable 17 is fixedly connected with rollers 18 equidistant and circularly distributed, which can assist the rotation of the turntable 17 and make the rotation process of the turntable 17 smoother.

[0031] The limit mechanism comprises a movable plate 9, a stop plate 5 and a slide bar 13. The top outer wall of the li...

Embodiment 2

[0038] refer to Figure 5 , a lifting device for building materials in construction engineering. Compared with Embodiment 1, this embodiment also includes sleeves 21 fixedly connected to the four corners of the bottom outer wall of the lifting box 1, and the top inner wall of the sleeve 21 is fixedly connected to There is a spring 24, one end of the spring 24 is fixedly connected with a telescopic rod 22, and the bottom outer wall of the telescopic rod 22 is fixedly connected with a support plate 23.

[0039] Working principle: When in use, when the lifting box 1 falls to the ground, the support plate 23 first contacts the ground, and then the telescopic rod 22 is urged to compress the spring 24 in the sleeve 21, which can play a certain buffering role, so that the lifting box 1 1 It is more stable when landing, and the use effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com