Reinforcing steel bar positioning device and platform integrated structure capable of being quickly assembled and disassembled

A positioning device and steel bar technology, applied in auxiliary forming equipment, ceramic forming machines, manufacturing tools, etc., can solve problems such as difficulty in lifting steel bar skeletons, achieve the effects of improving construction quality, reducing safety risks, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further explained below in conjunction with the accompanying drawings.

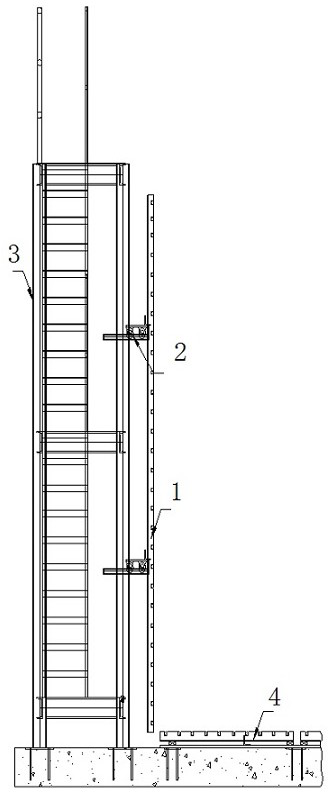

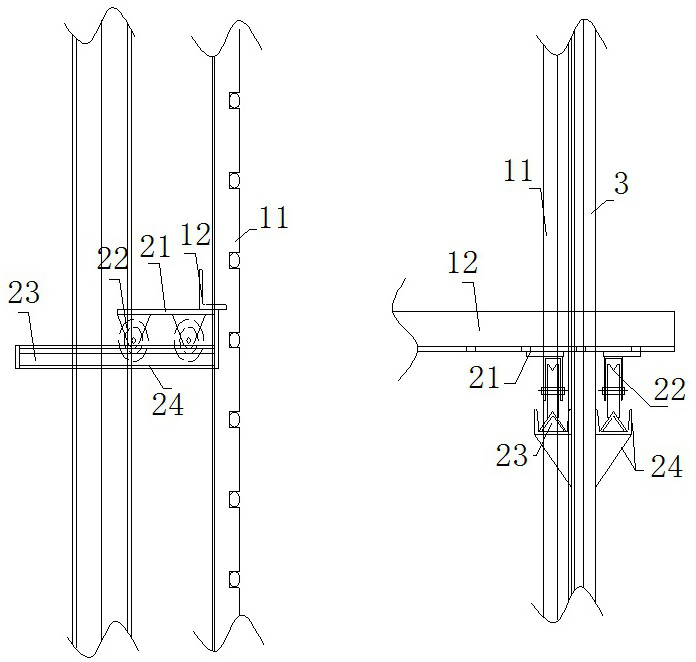

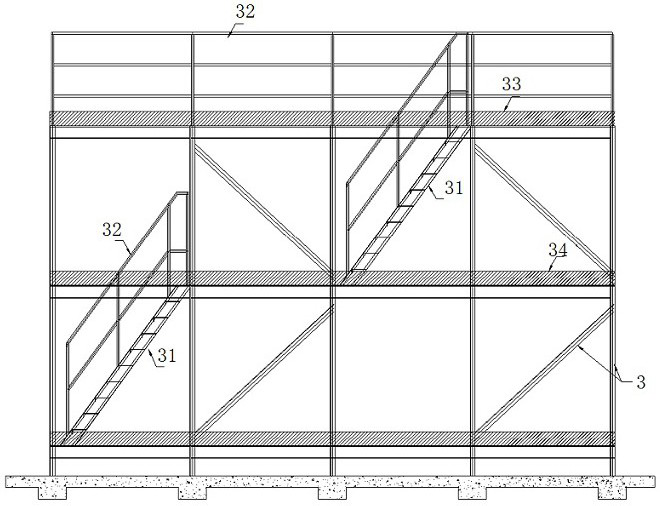

[0022] Control attached figure 1 , attached figure 2 , an integrated structure of a steel bar positioning device and a platform, comprising a lateral steel bar positioning system 1, a moving system 2, an operating platform system 3 and a bottom steel bar positioning system 4.

[0023] The lateral reinforcing bar positioning system 1 is composed of a lateral horizontal reinforcing bar positioning device 11 and a lateral vertical reinforcing bar positioning device 12, and completes the positioning operation of the lateral reinforcing bars. The operating platform system 3 and the mobile system 2 are respectively located on the integrated platform frame. A lateral horizontal steel bar positioning device 11 is installed on one side of the platform to complete the positioning and quick installation and removal of steel bars. Security facilities,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com