Self-moving advanced bracket

An advanced support and self-moving technology, applied in mine roof supports, mining equipment, earthwork drilling and mining, etc., can solve problems such as roof breakage, unfavorable roof safety management and maintenance, work efficiency, and low degree of mechanization, so as to improve management Horizontal, ensure integrity, structurally simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

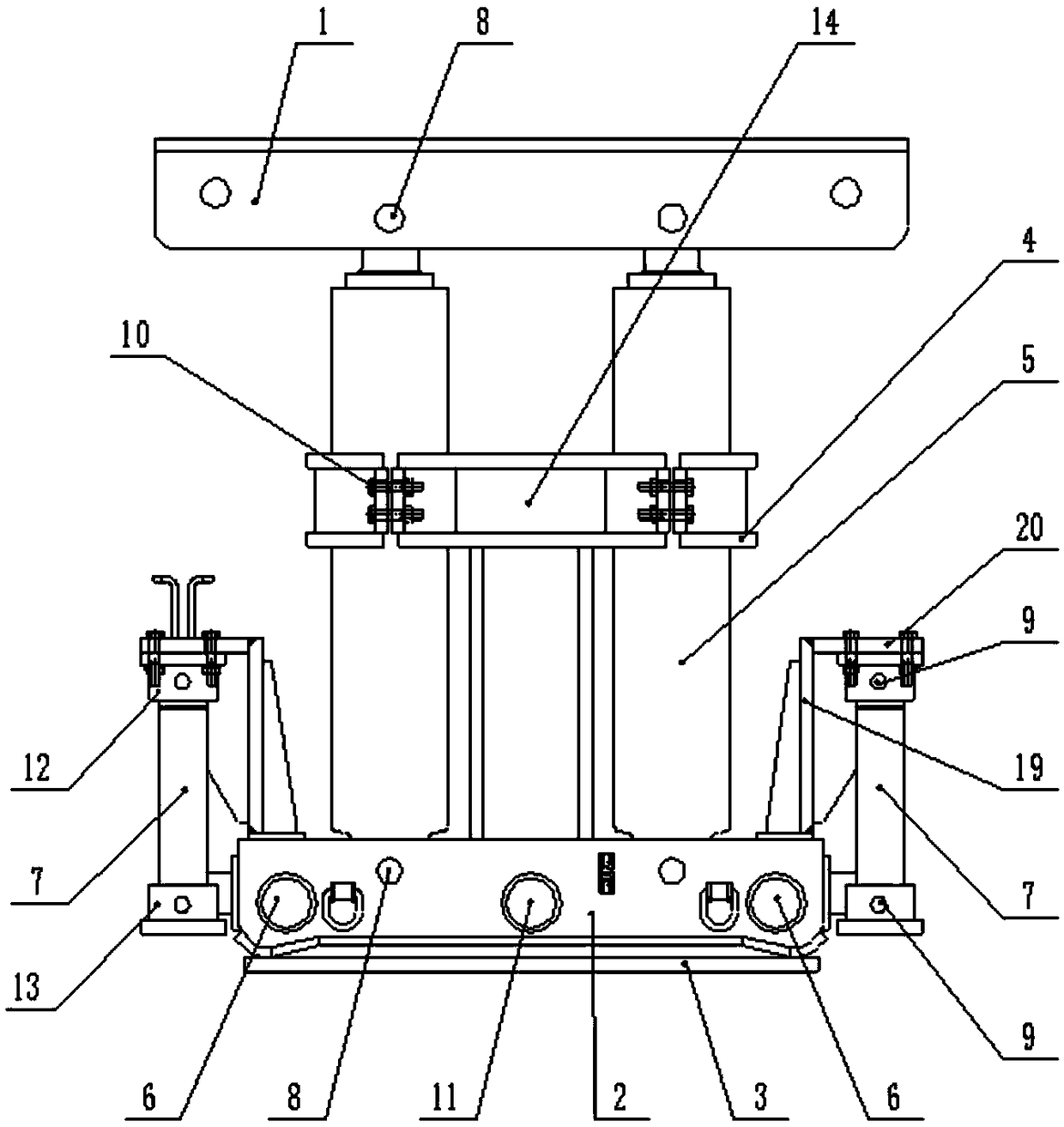

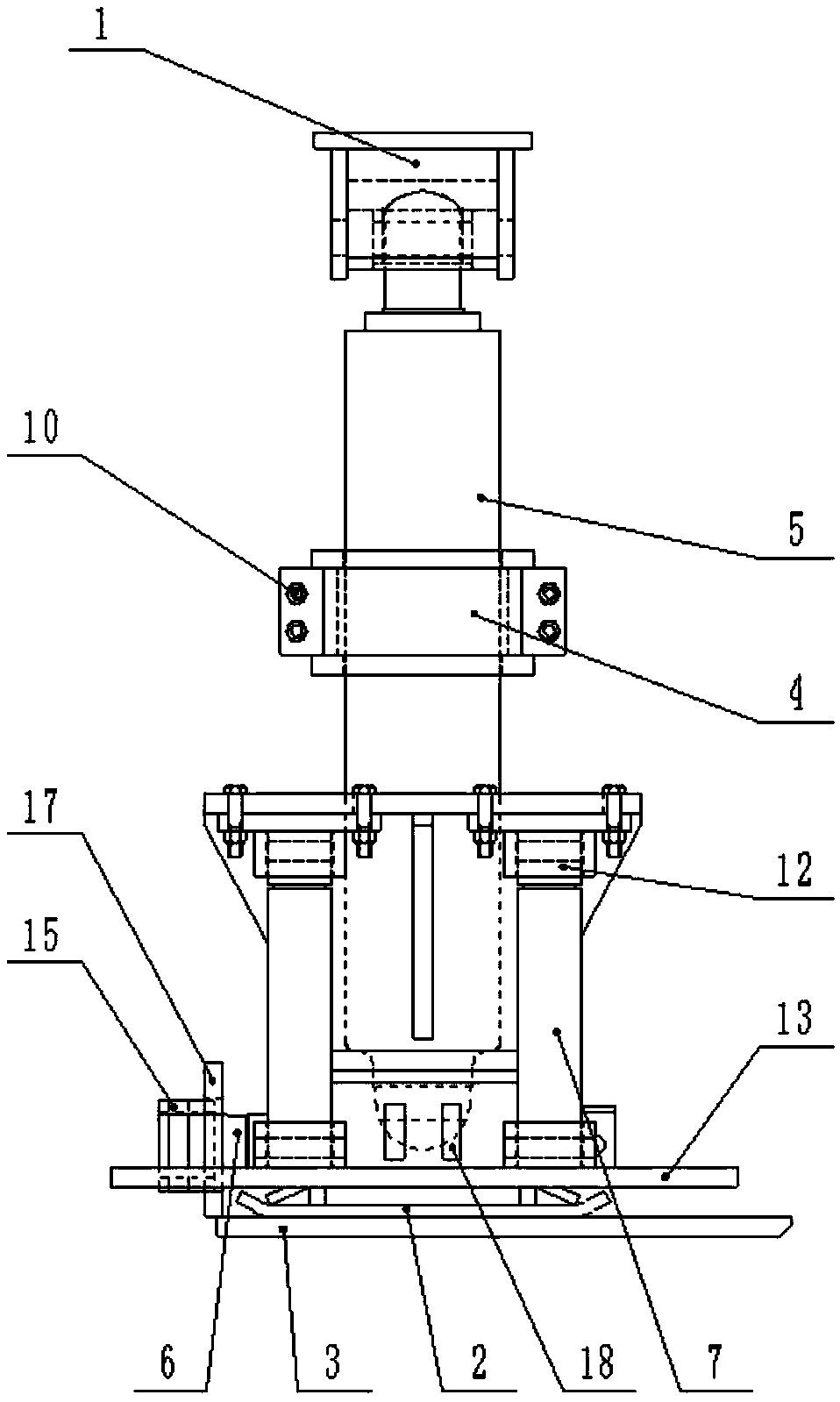

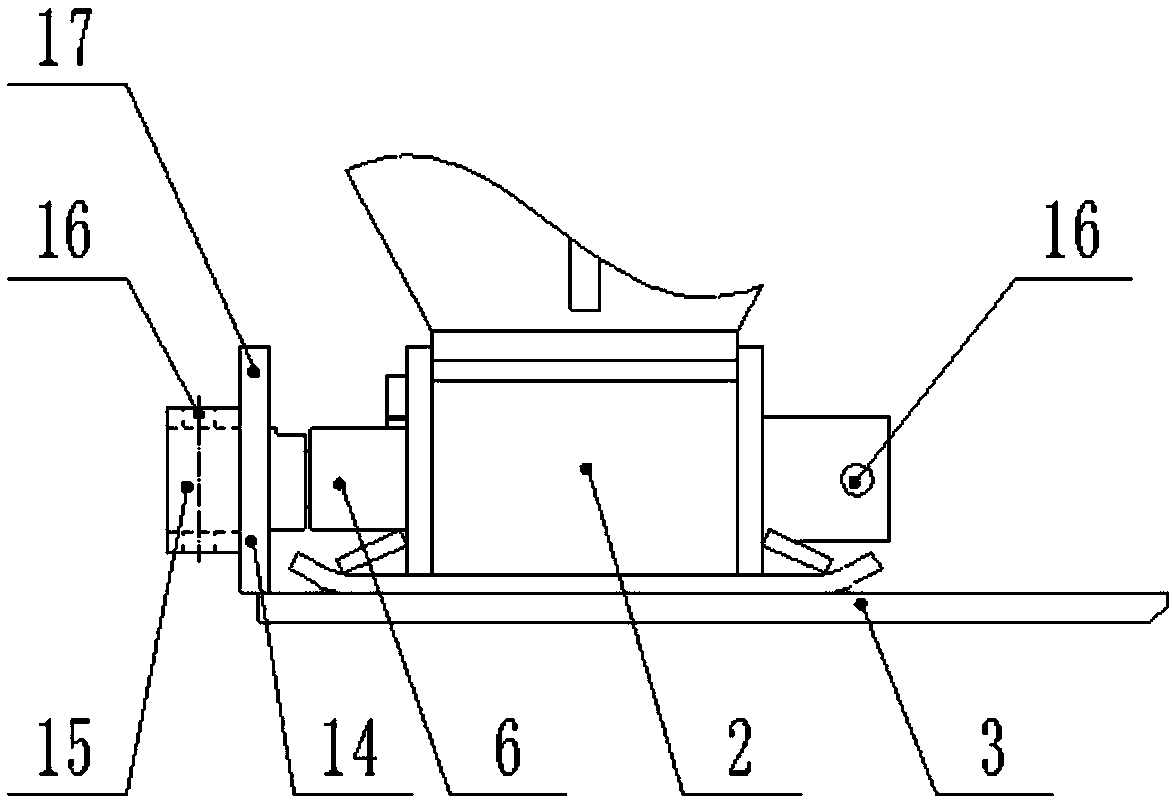

[0011] As attached figure 1 , 2 As shown, it includes a top beam 1, a base 2, a bottom plate 3, a column 5, a side push jack 6, and a support jack 7. The top beam 1 is a box structure, and the lower part of the base 2 is a box structure, and a bracket is welded on both sides. 19. Weld a horizontal connecting plate 20 on the bracket 19, and 8 bolt holes are opened on the connecting plate 20 (if attached Image 6 , 7 Shown); the piston rods at the upper end of the two uprights 5 are fixed to the top beam 1 by a pin 8 and the lower end is fixed on the base 2 by a pin 8; the two uprights 5 are connected by a fixed connection device, and the fixed connection device is a T-pillar 14 , Semi-circular arc-shaped pressing plate 4 and bolts 10, the T-shaped pillar 14 is a box type, welded to the middle position on the base 2, and two ends of the base 2 are respectively provided with an ear plate 18 for connecting traction equipment (if attached Image 6 , 7 ), both ends of the T-shaped pill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com