Two-rack reversible rolling device for rolling square and flat steel and steel rolling method thereof

A technology of square flat steel and rack, applied in the field of two-stand reversible rolling device, can solve the problems of low precision, unevenness, rolling piece mistakenly entering the pass pattern, etc., and achieve high positioning accuracy, good stability, and supporting force. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

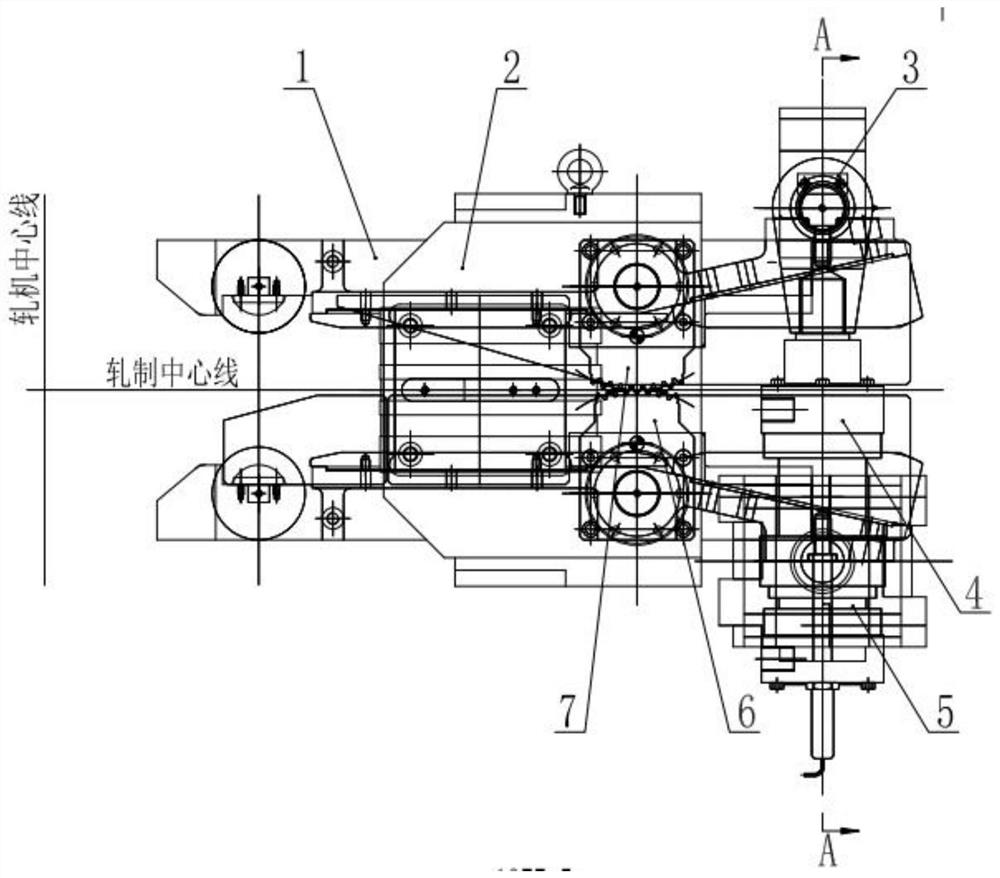

[0029] The invention provides a two-stand reversible rolling device for rolling square flat steel, which includes a stand, a rolling mill reversibly arranged on the stand, and a guide device connected with the rolling mill. The structure of the sanitary device is as figure 1 (mainly introducing the overall structure of the guide and guard device in the present invention), wherein, 1 is a swing arm, 2 is a guide and guard bracket, 3 is a clamping plate, 4 is an oil cylinder, 5 is a gland, 6 is a synchronous tooth plate 1, and 7 is a Synchronous tooth plate two.

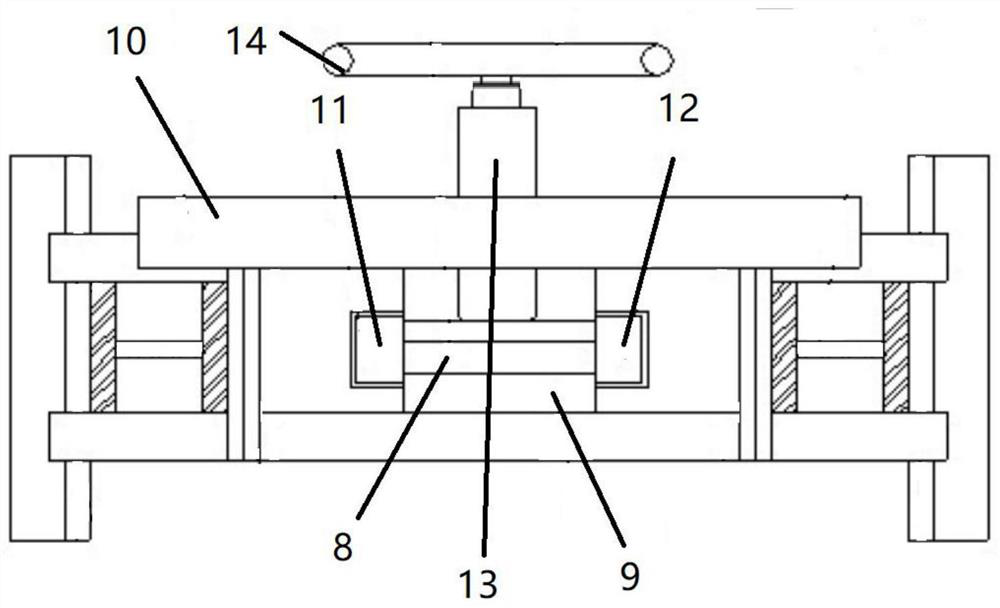

[0030] The above-mentioned guide and guard device is connected with the rolling mill by adopting the splint type with adjustable spacing and the combination of hydraulic drive and locking and fixing. Specifically, the guide and guard device is arranged between the upper and lower beams of the frame 10 through the upper splint 8 and the lower splint 9, and a left guide 11 and a right guide 12 are respectively installed...

experiment example 1

[0041] Adopt the device provided in the embodiment of the present invention to carry out the rolling of square flat steel,

[0042] The steel is made of high-temperature alloy, rolled by the device of the embodiment of the present invention, and counts whether the workpiece is deformed in 100 working processes of rolling, and records it as deformation with a difference of more than 2mm from the target size, examines the deformation rate, and uses the traditional two-stand Reverse rolling was rolled as a control. The results show that: the deformation rate of steel rolled by the device provided by the embodiment of the present invention is 1.5%, while the deformation rate of the control example is 10%.

experiment example 2

[0044]Adopt the device provided in the embodiment of the present invention to carry out the rolling of square flat steel,

[0045] The steel material selects stainless steel to carry out the test, adopts the device of the embodiment of the present invention to carry out rolling, counts whether deformation occurs in the workpiece during 100 working processes of rolling, records as deformation with a difference of more than 2mm from the target size, examines the deformation rate, and uses the traditional two machine The reversible rolling of the rack was carried out as a control, and the results showed that the deformation rate of steel rolled by the device provided in the embodiment of the present invention was 0.5%, while the deformation rate of the control example was 5%.

[0046] By adopting the above-mentioned guide and guard device of the present invention, carry out the square flat steel rolling work as long as one year, and count the production situation and accident situ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com