Plasma waste gas treatment equipment

A technology for waste gas treatment equipment and plasma, applied in gas treatment, lighting and heating equipment, separation methods, etc., can solve the problems of slow waste gas filtration, unfavorable use, poor filtration quality, etc., to achieve the effect of strengthening filtration, strong wind power, wide area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

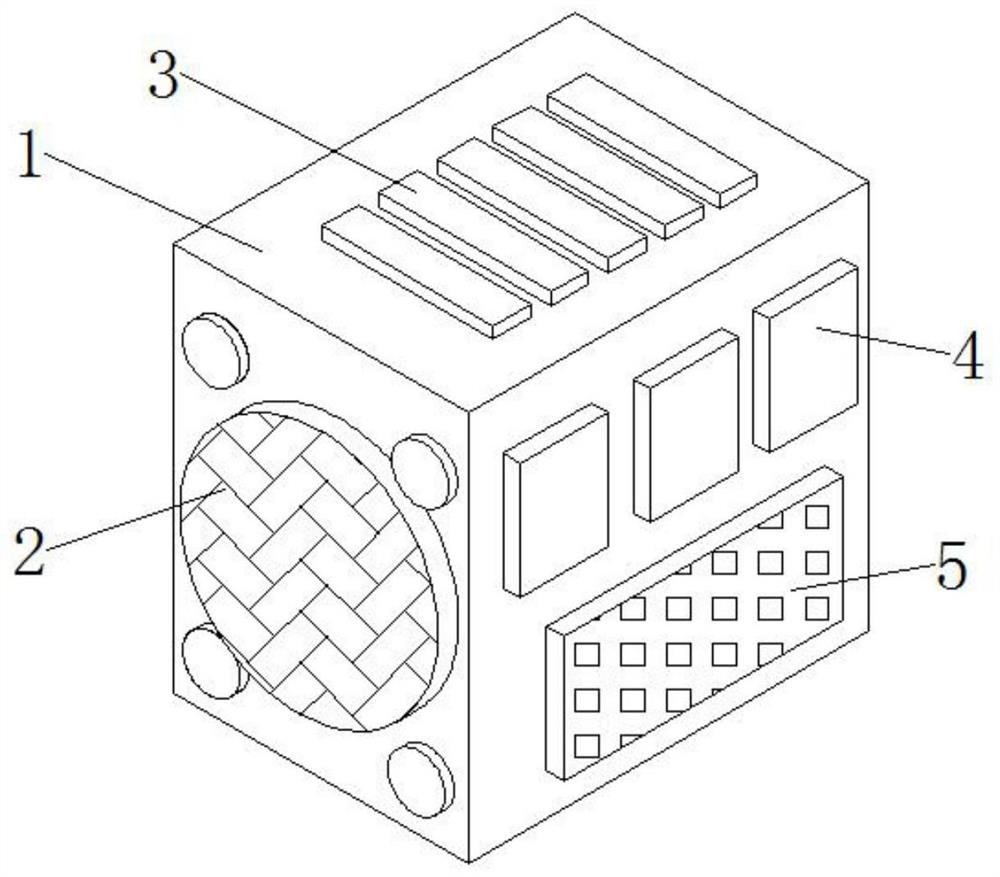

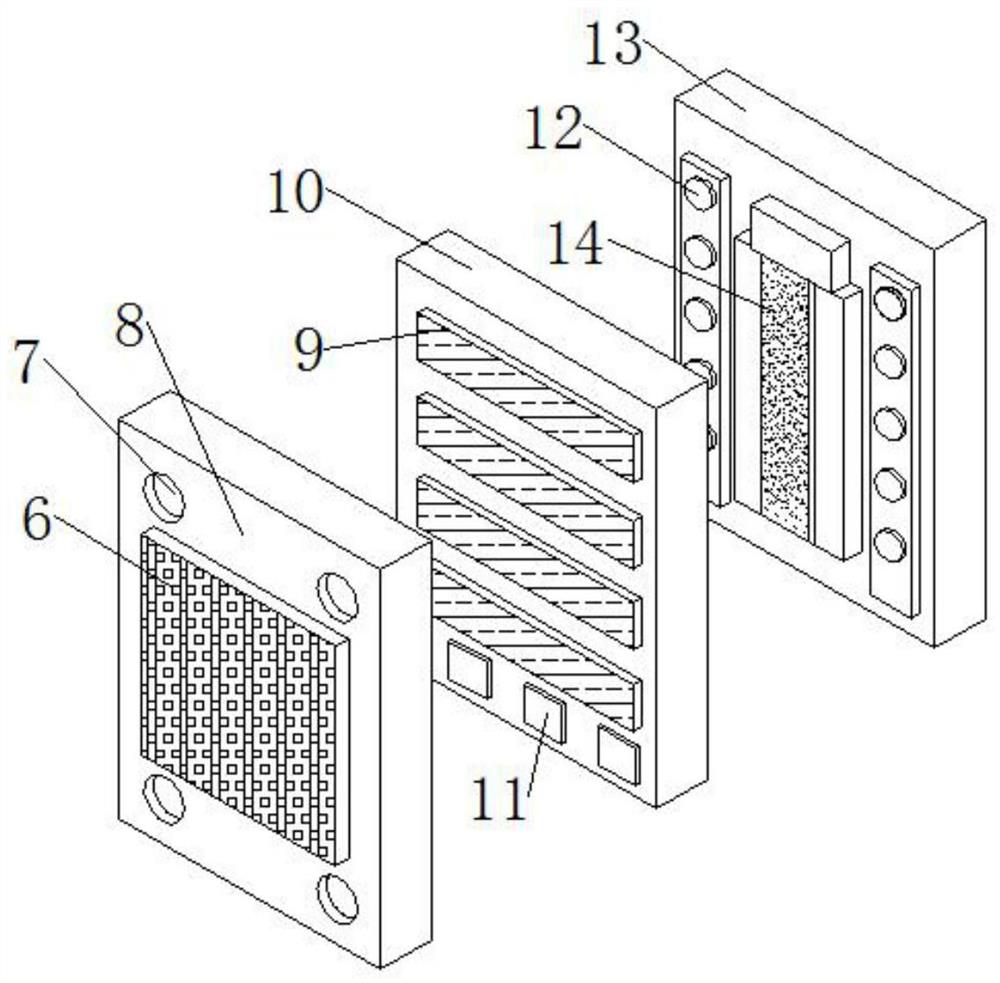

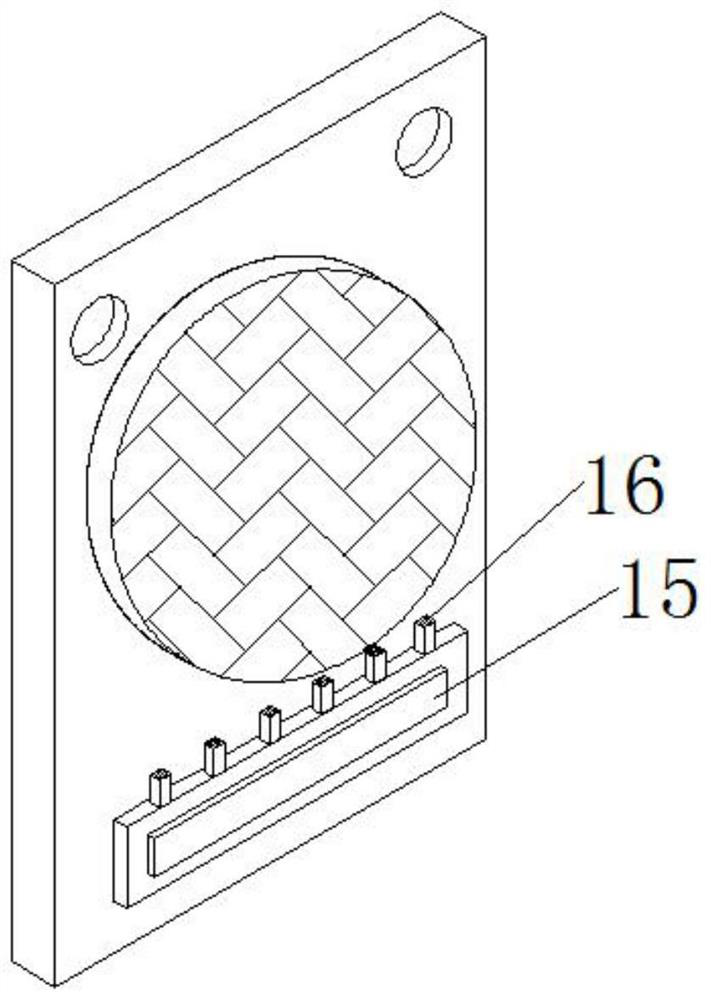

[0025] refer to Figure 1-4 ,

[0026] A plasma exhaust gas treatment device provided in this embodiment includes a chassis 1, an air outlet 2 and a cooling outlet 3, the air outlet 2 is located on the left side outside the chassis 1, and the air outlet 2 is movably connected to the chassis 1, and the top of the chassis 1 is provided with a heat dissipation port 3, and the heat dissipation port 3 is fixedly connected to the chassis 1, the upper right side outside the chassis 1 is provided with a wire storage box 4, and the wire storage box 4 is fixedly connected to the chassis 1, and the lower right side outside the chassis 1 is provided with a control box 5, and The control box 5 is fixedly connected with the cabinet 1, the inside of the cabinet 1 is provided with a filter panel 8, and the filter panel 8 is movably connected with the cabinet 1, and the left side of the filter panel 8 is provided with a primary filter 6, and the primary filter 6 is fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com