Synergistic low-foam trifluoro bentazone water aqua aid and preparation process thereof

A technology of triflufenazone and water preparation, applied in the field of pesticides, can solve problems such as increased drug cost, impact on crop safety, ecological environment pollution, etc., achieve excellent heat resistance and chemical stability, improve herbicidal effect, and surface activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

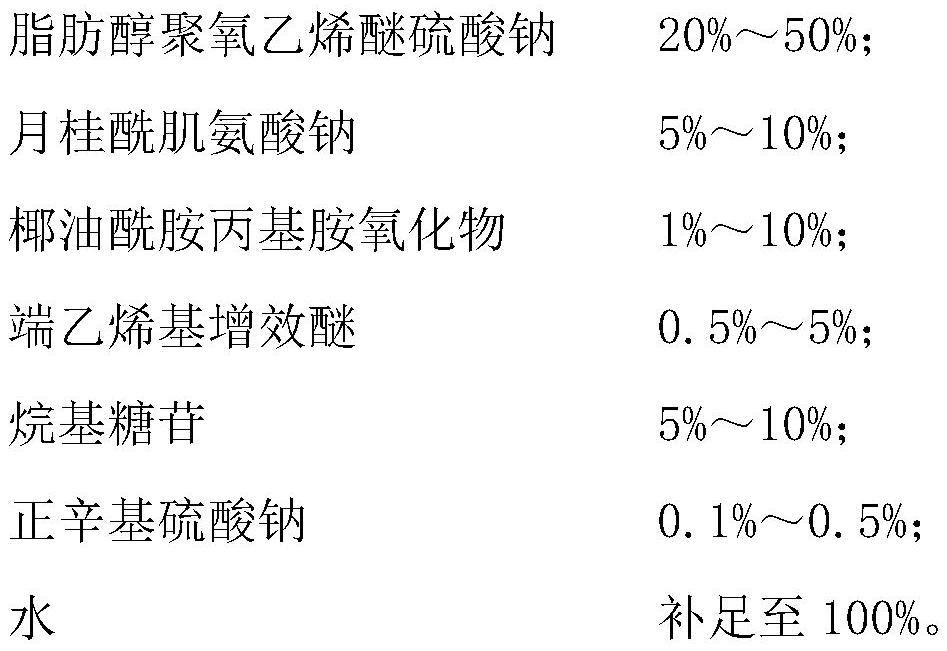

Method used

Image

Examples

Embodiment 1

[0024] Take the following weights: mix measured 5% alkyl glucoside, 5% sodium lauroyl sarcosinate, and 5% cocamidopropyl betaine into the reaction kettle, stir evenly, add water, heat to 60°C and continue stirring 15-30 minutes, add the weighed 25% sodium fatty alcohol polyoxyethylene ether sulfate, 2% vinyl-terminated butyroxylate and 0.1% n-octyl sodium sulfate to the above product, stir at 60°C for 20-40 Minutes, then supplemented with deionized water, and stirred evenly to obtain a synergistic low-foaming type triflumazone water adjuvant.

[0025] Viscosity determination of the prepared synergistic low-foaming type triflumazone water adjuvant:

[0026] Instrument: NDJ-79 rotary viscometer

[0027] Test temperature: room temperature;

[0028] Rotor: No. 1 rotor, speed: 12 rpm;

[0029] The viscosity of the special synergist measured by a rotary viscometer is 205mPa.s.

[0030] Surface Tension Determination:

[0031] Instrument: contact angle / surface and interfacial ten...

Embodiment 2

[0039] Take the following weight materials: mix the metered 7% alkyl glucoside, 10% sodium lauroyl sarcosinate, and 6% cocamidopropyl betaine into the reaction kettle, stir well, add water, heat to 60°C and continue stirring 15-30 minutes, add the weighed 30% sodium fatty alcohol polyoxyethylene ether sulfate, 3% vinyl-terminated synergistic ether and 0.1% n-octyl sodium sulfate to the above product, stir at 60°C for 20-40 Minutes, then supplemented with deionized water, and stirred evenly to obtain a synergistic low-foaming type triflumazone water adjuvant.

[0040] According to the test method of Example 1, the synergistic low-foaming type triflumazone water adjuvant prepared by this formula has a pH value of 5.8, a viscosity of 235mPa.s, a surface tension of 17.8mN / m, and a foaming of 20mL.

Embodiment 3

[0042] Take the following weight materials: mix the measured 10% alkyl glucoside, 10% sodium lauroyl sarcosinate, and 8% cocamidopropyl betaine into the reaction kettle, stir well, add water, heat to 60°C and continue stirring 15-30 minutes, add the weighed 35% fatty alcohol polyoxyethylene ether sodium sulfate, 4% vinyl-terminated butyroxylate and 0.2% n-octyl sodium sulfate to the above product, stir at 60°C for 20-40 Minutes, then supplemented with deionized water, and stirred evenly to obtain a synergistic low-foaming type triflumazone water adjuvant.

[0043] According to the test method of Example 1, the pH value of the synergistic low-foaming triflumazone water adjuvant prepared by this formula is 5.85, the viscosity is 285mPa.s, the surface tension is 16.5mN / m, and the foaming is 20mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com