Foamable oil-in-water type emulsified oil or fat composition

An oil-in-water type, emulsified grease technology, applied in the direction of edible oil/fat, edible oil/fat phase, dairy products, etc., can solve problems such as foaming, flavor problems, and insufficient dehydration resistance, etc., to achieve Odor suppression, good dehydration resistance, good foaming and dope stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

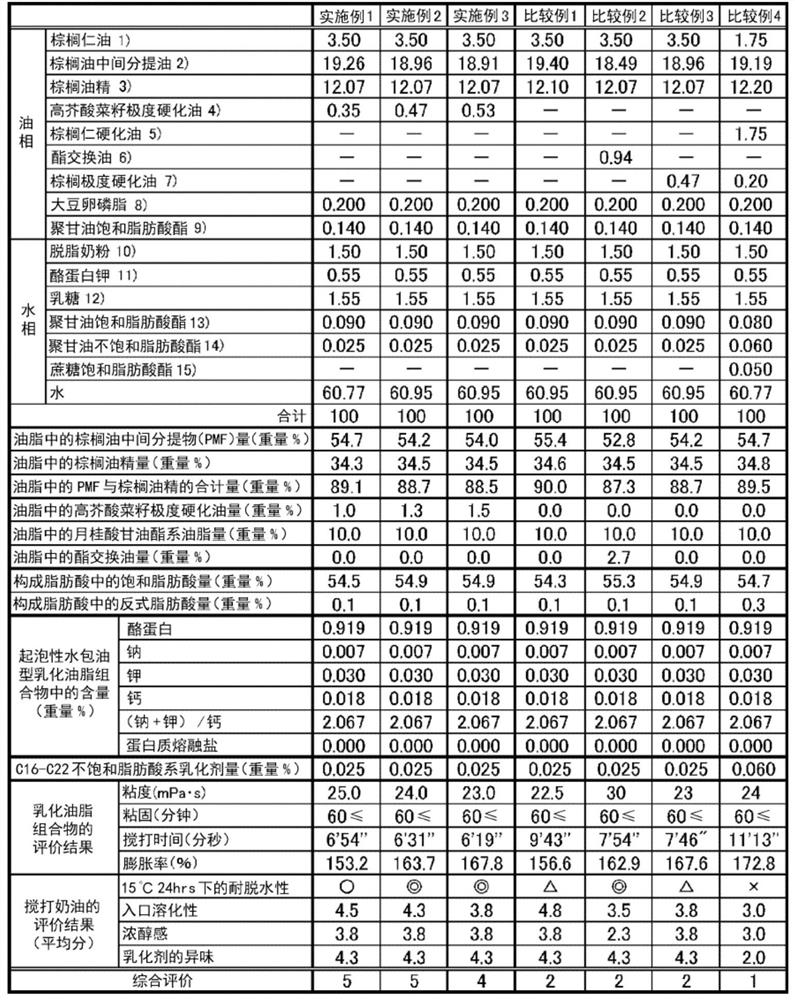

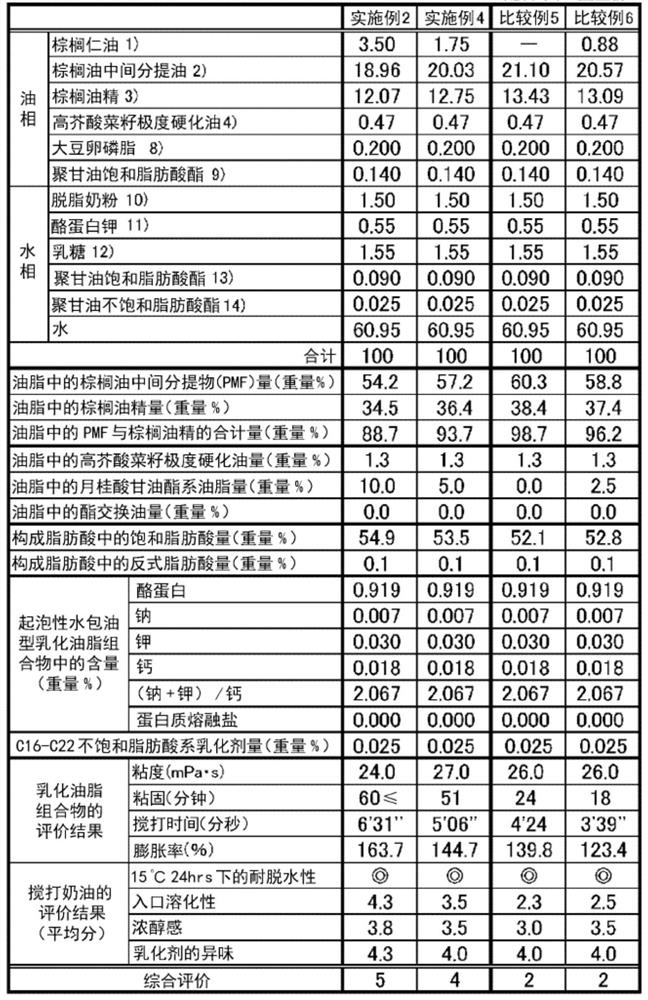

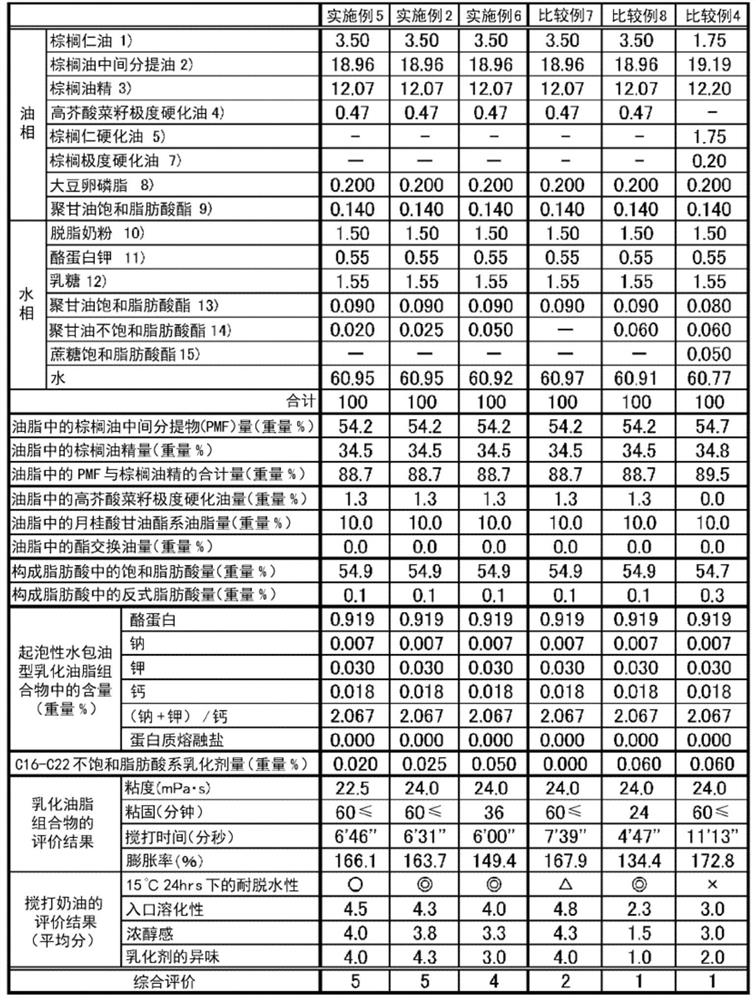

[0127] (Example 1) Foamable oil-in-water emulsified fat composition and whipped cream

[0128] According to the coordination in Table 1, 3.50 parts by weight of palm kernel oil (rising melting point: 27°C, trans fatty acid: 0% by weight, total saturated fatty acid: 79.9%), palm oil middle fraction (trans fatty acid: 0.1 % by weight, total saturated fatty acid: 55.6% by weight) 19.26 parts by weight, palm olein (trans fatty acid: 0.2% by weight, total saturated fatty acid: 45.9% by weight) 12.07 parts by weight and canola oil (trans type Fatty acid: 0% by weight, total saturated fatty acid: 99.9% by weight) 0.35% by weight of the oil mixture, add 0.200% by weight of soybean lecithin, 0.140% by weight of polyglycerin saturated fatty acid ester (HLB: 8.4), and dissolve at 65°C. An oil phase part was prepared. At this time, the trans fatty acid content was 0.1% by weight and the saturated fatty acid content was 54.5% by weight in all fatty acids constituting the fats and oils in ...

Embodiment 2

[0136] According to the compounding in Table 1, the compounding amount of the palm oil intermediate fraction was changed to 18.96 parts by weight, and the compounding amount of canola oil was changed to 0.47 parts by weight, except that it was the same as in Example 1 A foamable oil-in-water emulsified fat composition and whipped cream were obtained.

Embodiment 3

[0138] According to the compounding in Table 1, the compounding amount of the palm oil intermediate fraction was changed to 18.91 parts by weight, and the compounding amount of canola oil was changed to 0.53 parts by weight, except that it was the same as Example 1 A foamable oil-in-water emulsified fat composition and whipped cream were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com