Hybrid-driven ballastless track fatigue life prediction method and system

A technology of fatigue life prediction and ballastless track, applied in neural learning methods, details involving 3D image data, image data processing, etc., can solve problems such as poor persuasion and practicability, inaccuracy, long cycle, etc. Sufficient and highly predictive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

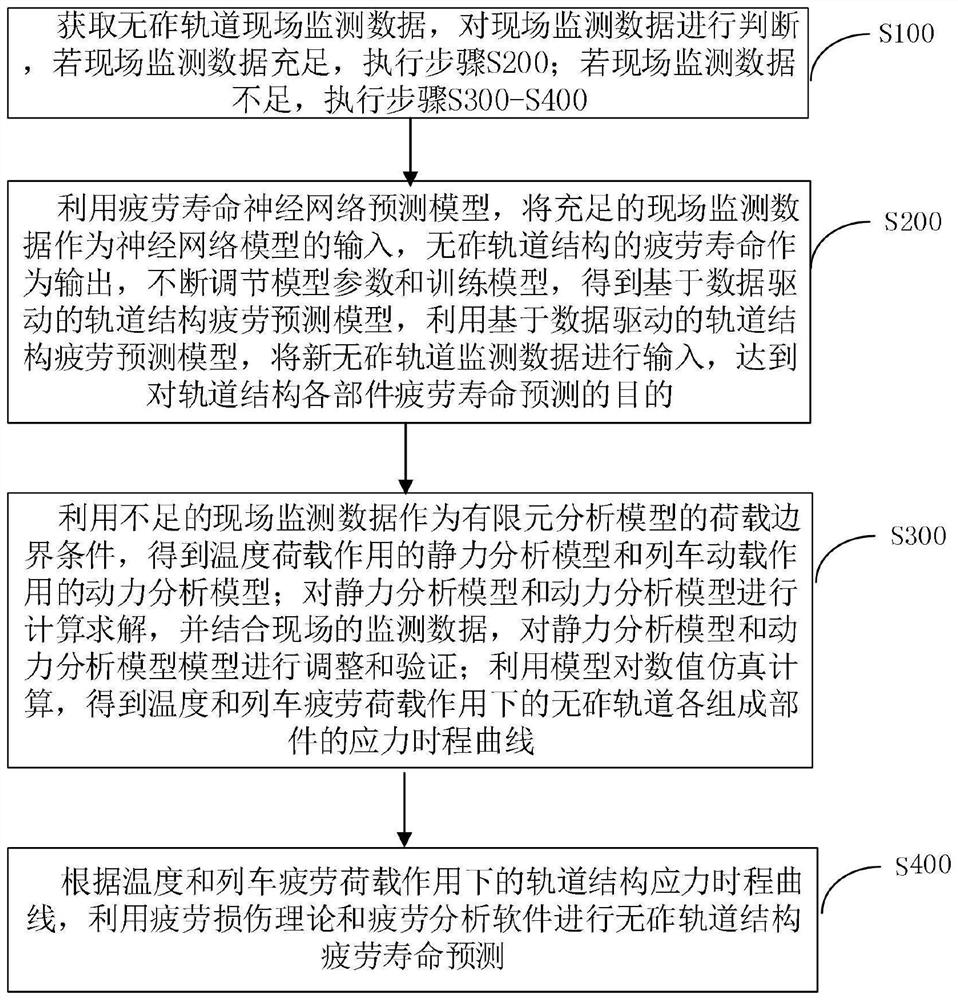

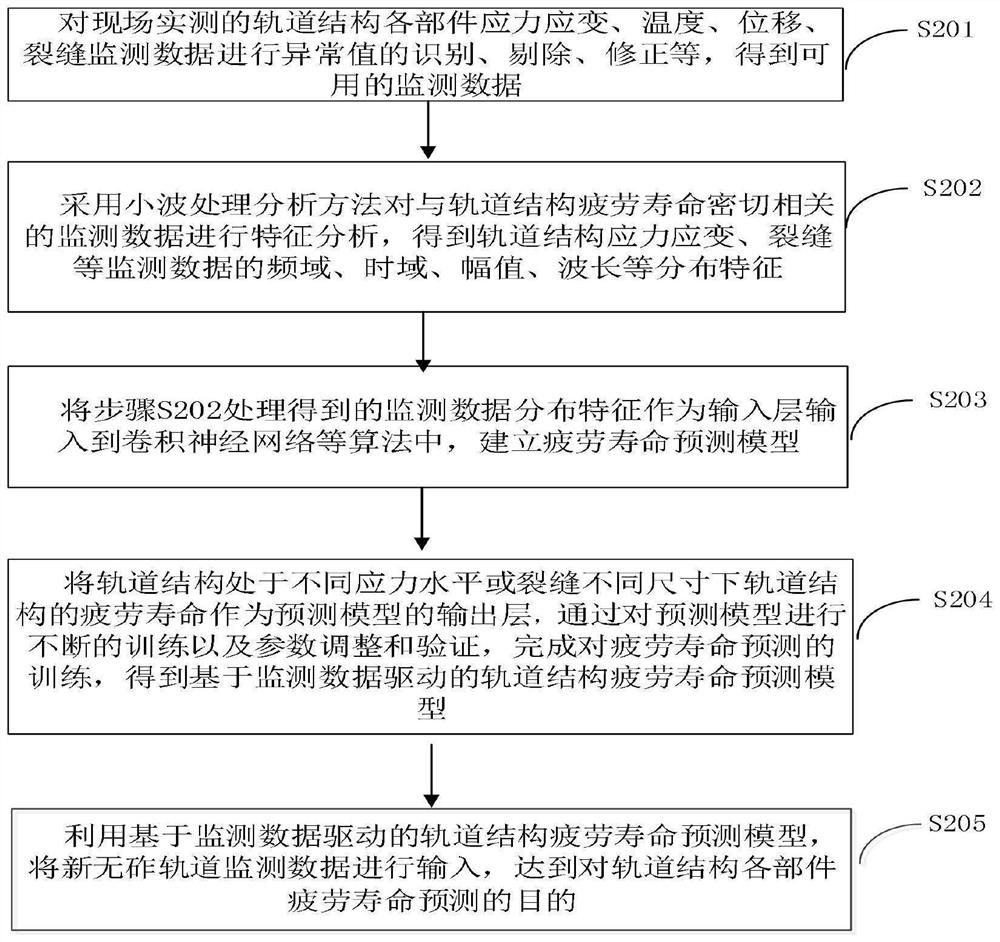

[0050] This embodiment discloses a hybrid drive ballastless track fatigue life prediction method, such as figure 1 ,include:

[0051] S100. Obtain on-site monitoring data of the ballastless track, and judge the on-site monitoring data. If the on-site monitoring data is sufficient, perform step S200; if the on-site monitoring data is insufficient, perform steps S300-S400.

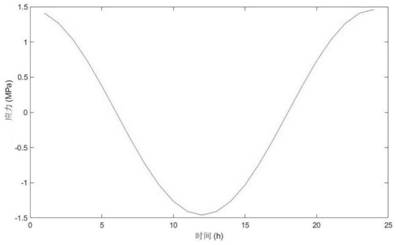

[0052] Specifically, the monitoring data includes temperature monitoring data, such as atmospheric temperature and the temperature of each structural layer of the ballastless track; stress and strain monitoring data, such as the stress and strain of steel rails and internal steel bars and concrete in the track structure, etc.; Relative displacement between structural layers, etc.; crack and interface separation monitoring data, including the number of cracks and separation, joint size, spacing, etc.

[0053] In some preferred embodiments, the monitoring data mainly comes from the on-site ballastless track u...

Embodiment 2

[0084] This embodiment discloses a hybrid drive ballastless track fatigue life prediction system, such as Figure 8 , including: monitoring data judgment module 1, monitoring data intelligent learning module 2, finite element theory numerical simulation analysis module 3, fatigue life damage prediction analysis module 4; wherein:

[0085] The monitoring data judgment module 1 receives the ballastless track monitoring data sent by the monitoring platform, uses preset rules to judge the monitoring data, and sends the monitoring data to the monitoring data intelligent learning module 2 and the finite element theory numerical simulation analysis module respectively according to the judgment results 3.

[0086] Specifically, the monitoring data judgment module 1 judges the monitoring data according to the following rules: if the on-site monitoring data is sufficient, the monitoring data is sent to the monitoring data intelligent learning module 2; if the on-site monitoring data is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com