Parameterized machining method of rack on numerical control planer type milling machine

A technology of gantry milling machine and processing method, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of cumbersome programming and large amount of programs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments described below are only preferred modes and are not intended to limit the protection scope of the present invention.

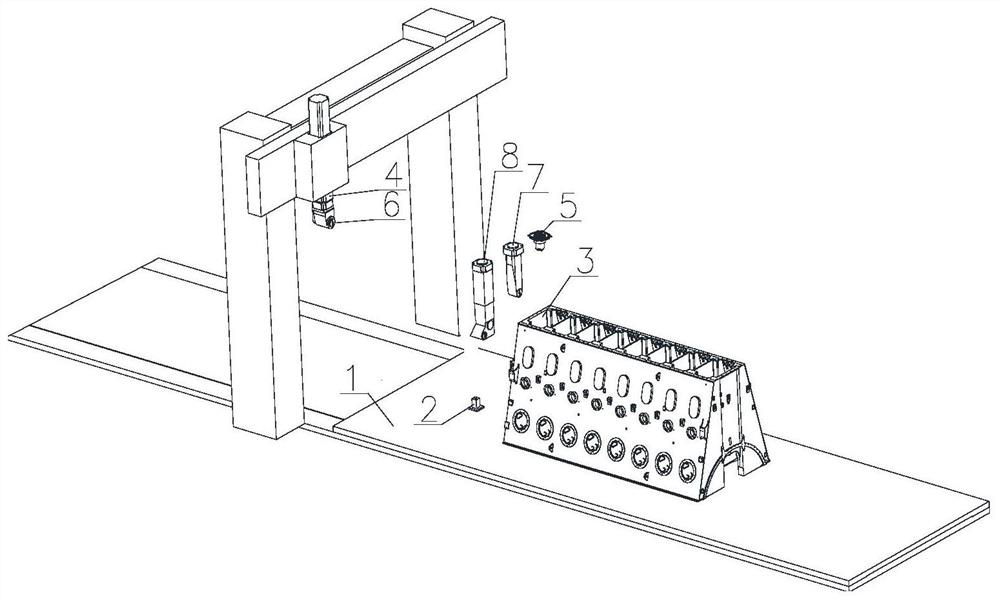

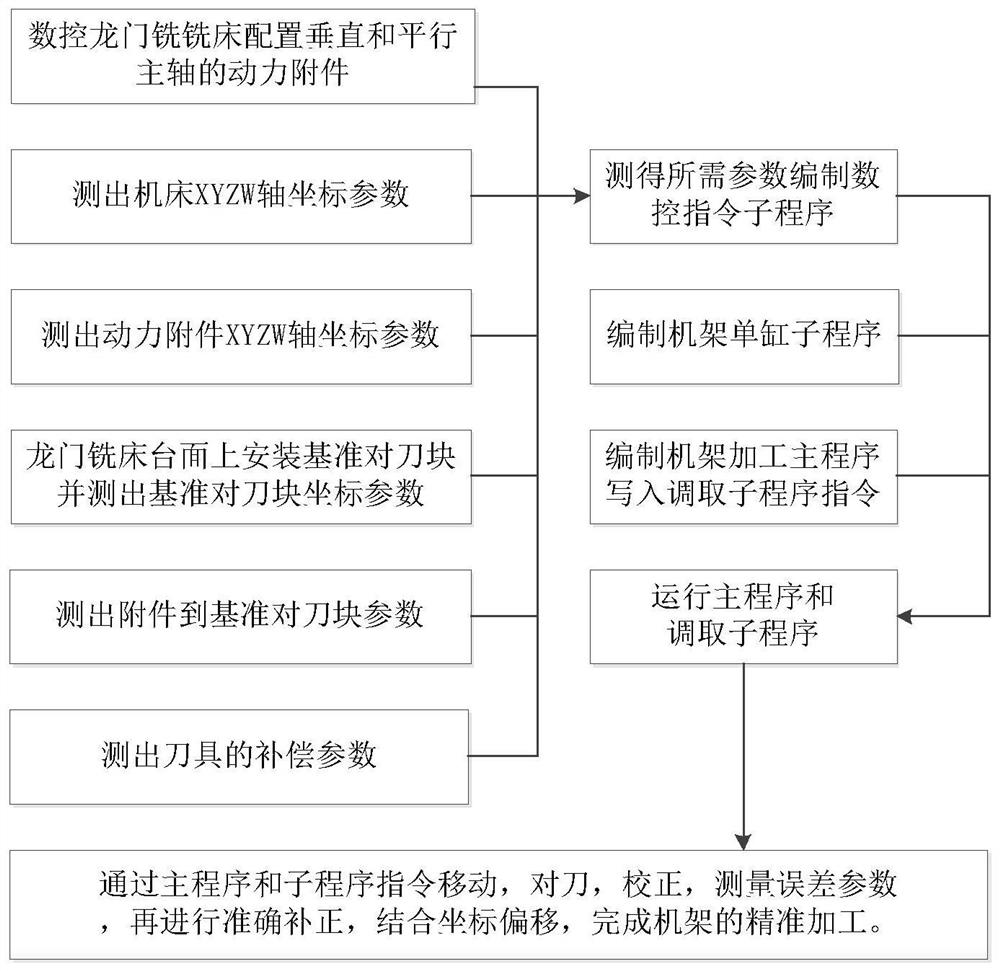

[0024] A parametric processing method of a frame on a CNC gantry milling machine according to the present invention configures the power accessories of the vertical and parallel spindles on the NC gantry milling machine, installs a reference tool setting block on the milling machine table, and measures the machine tool spindle, power The coordinate parameters of the accessories and the reference tool setting block and the compensation parameters of the tool, and then according to the measured parameters, the single-cylinder machining NC subroutine and the main program for calling the NC subroutine are compiled, and the main program and subroutine are run to realize movement, Tool setting, correction, measurement error and accurate correction, combined with coordinate offset, complete the precise machining of the rack.

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com