Speed measurement anti-settling erosion corrosion test device and test method thereof

A technology of erosion corrosion and test equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, fluid velocity measurement, etc., can solve the problem of lack of effective control of test temperature, serious settling, and inability to measure the relative velocity of the sample and fluid And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

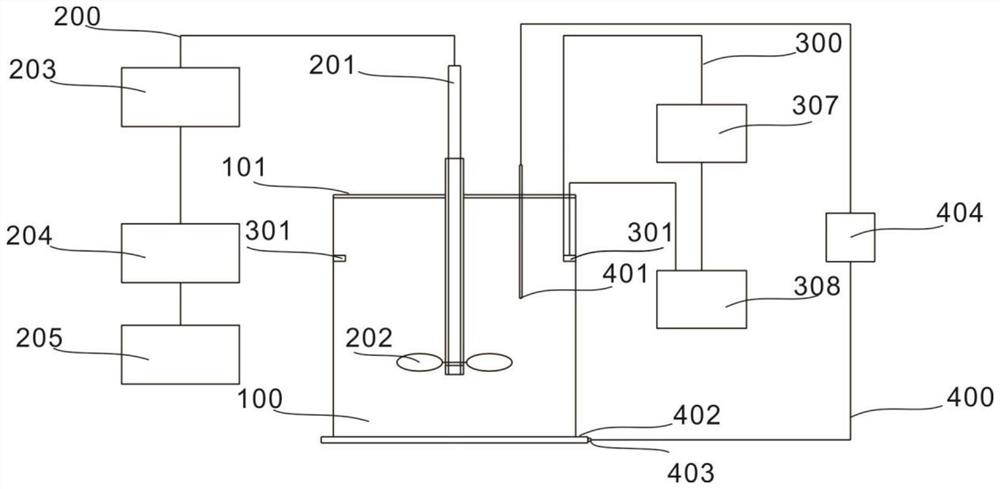

[0033] refer to Figure 1 to Figure 6 , which is the first embodiment of the present invention, provides a speed measurement anti-settling erosion corrosion test device, this speed measurement anti-settling erosion corrosion test device includes a tank 100, a rotating system 200 and an electrochemical analysis system 300. The tank body 100 is a cylindrical structure, and the top of the tank body 100 is covered with a sealing cap 101 .

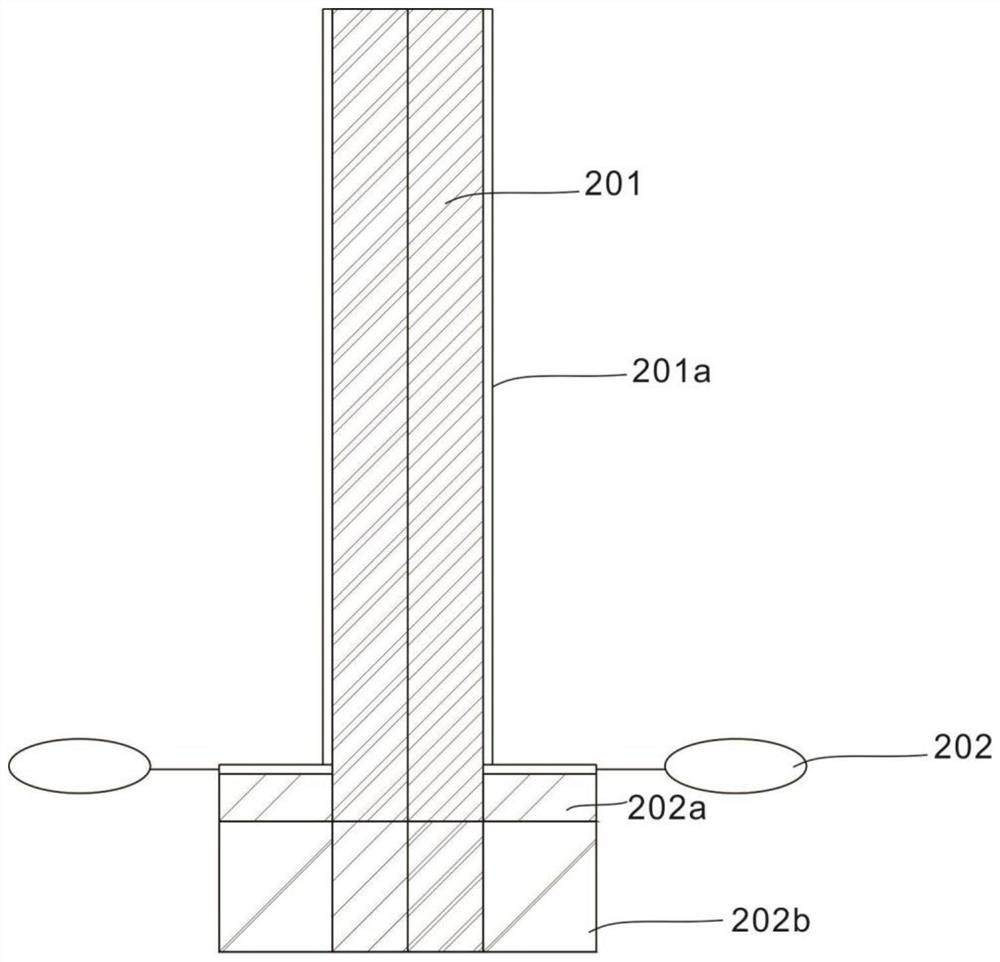

[0034] The rotating system 200 includes a rotating shaft 201, which extends into the tank body 100 through the sealing cover 101. In order to prolong the service life of the rotating shaft 201, the rotating shaft 201 is covered with a protective sleeve 201a, and the protective sleeve 201a is removed from the tank body 100. Extending out of the tank body 100, the protective cover 201a of the present invention can be a rubber sleeve. At the same time, the present invention can also be provided with a rubber ring outside the protective cover 201a,...

Embodiment 2

[0050] refer to figure 2 , is the second embodiment of the present invention, which differs from the first embodiment in that: the turbine blades 202 are detachably mounted on the end of the rotating shaft 201 .

[0051] Compared with Example 1, further, this speed measurement anti-settling erosion corrosion test device includes a tank body 100 , a rotating system 200 and an electrochemical analysis system 300 . The tank body 100 is a cylindrical structure, and the top of the tank body 100 is covered with a sealing cap 101 .

[0052] The rotating system 200 includes a rotating shaft 201, which extends into the tank body 100 through the sealing cover 101. In order to prolong the service life of the rotating shaft 201, the rotating shaft 201 is covered with a protective sleeve 201a, and the protective sleeve 201a is removed from the tank body 100. Extending out of the tank body 100, the protective cover 201a of the present invention can be a rubber sleeve. At the same time, th...

Embodiment 3

[0070] refer to Figure 5 , is the third embodiment of the present invention, and this embodiment is different from the second embodiment in that: the ends of the upper section body 301a and the lower section body 301b away from the folded connection are respectively equipped with a plunger and a slot, and the plunger The insertion slots further fix the positions of the upper body 301a and the lower body 301b.

[0071] Compared with Example 2, further, this speed measurement anti-settling erosion corrosion test device includes a tank body 100 , a rotating system 200 and an electrochemical analysis system 300 . The tank body 100 is a cylindrical structure, and the top of the tank body 100 is covered with a sealing cap 101 .

[0072] The rotating system 200 includes a rotating shaft 201, which extends into the tank body 100 through the sealing cover 101. In order to prolong the service life of the rotating shaft 201, the rotating shaft 201 is covered with a protective sleeve 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com