Bolt loosening positioning detection method based on working mode strain fiber bragg grating sensing

A fiber grating and working modal technology, which is applied in the field of bolt loosening positioning detection based on working modal strain fiber grating sensing, can solve the problems of decreased recognition accuracy, difficulty in image recognition methods to meet actual needs, covered by dirt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

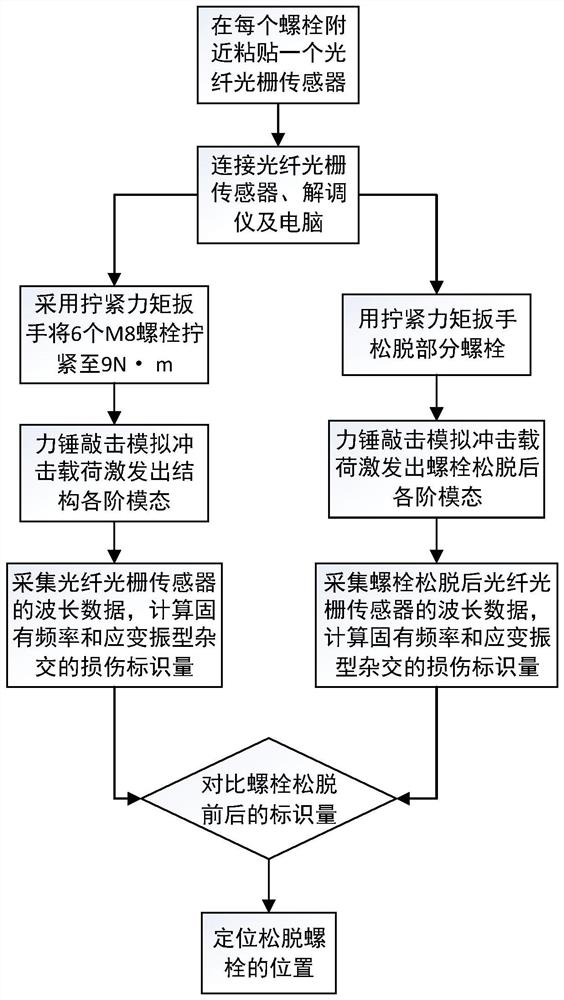

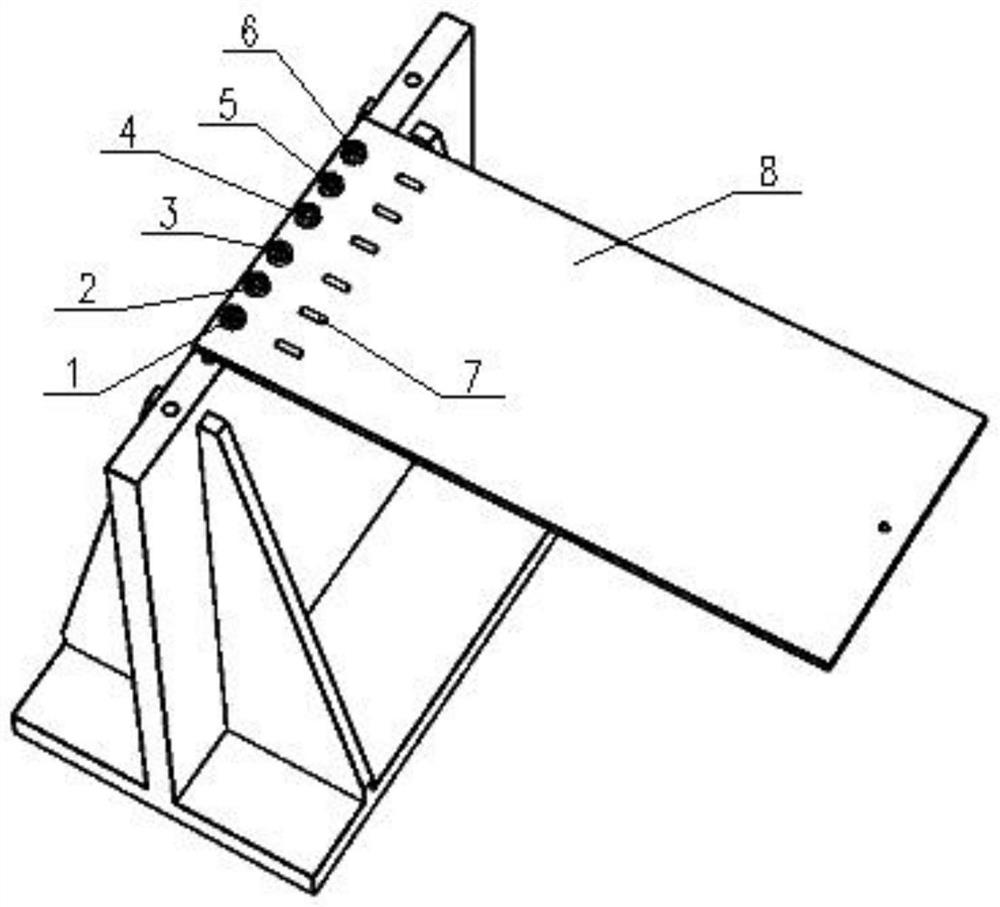

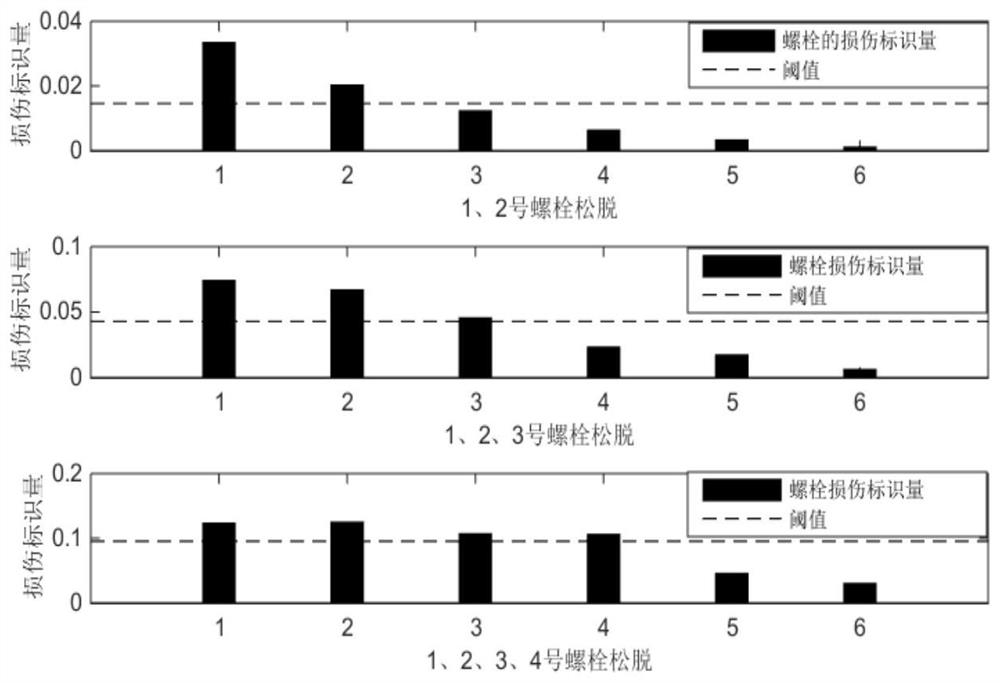

[0016] In an embodiment of the present invention, a method for detecting bolt looseness based on working mode strain-fiber grating sensing is provided, such as figure 1 , figure 2 , image 3 shown. The specific operation process is as follows:

[0017] (1) in figure 2 A fiber grating sensor 7 is attached to the middle bolts 1-6;

[0018] (2) Connect the fiber grating sensor, demodulator and computer;

[0019] (3) Tighten six M8 bolts to 9N m with a tightening torque wrench;

[0020] (4) Run the software system of the demodulator, knock the thin plate 8 with a force hammer, simulate the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com