Blast furnace lining thickness calculation device and method based on distributed optical fiber temperature measurement

A technology of distributed optical fiber and calculation method, which is applied in thermometers, measuring devices, thermometers with physical/chemical changes, etc. problem, to achieve the effect of rapid positioning and reducing the risk of safety production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

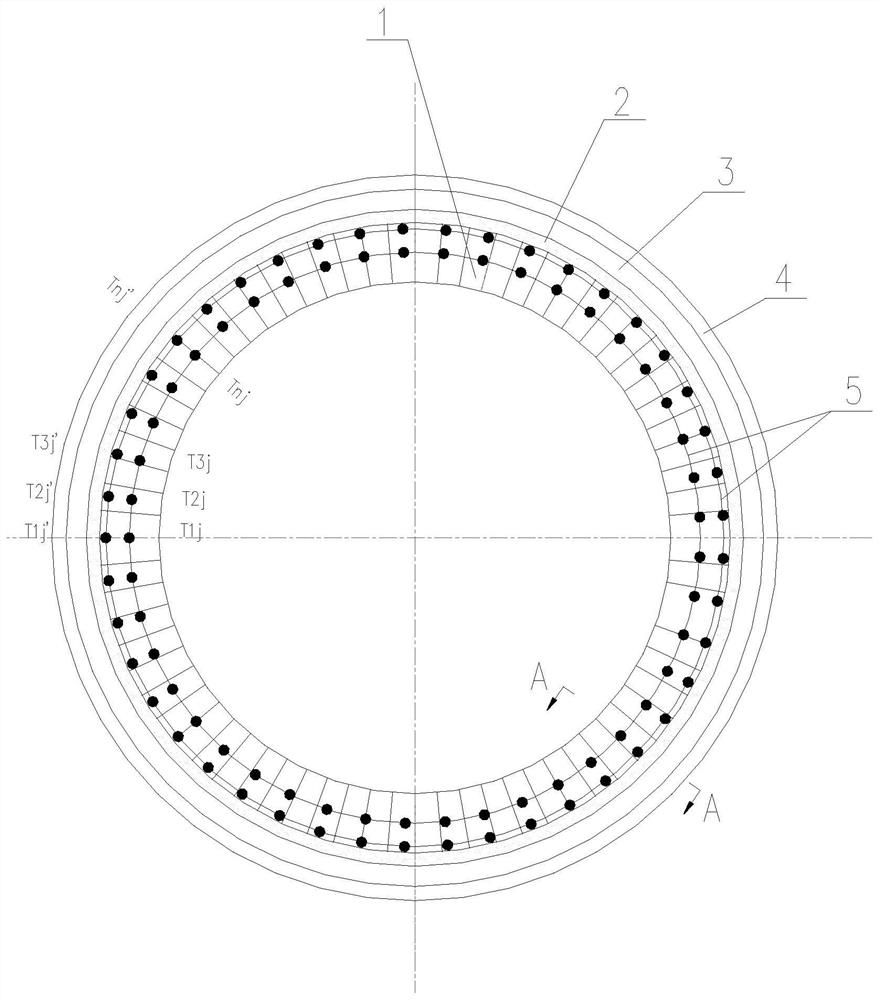

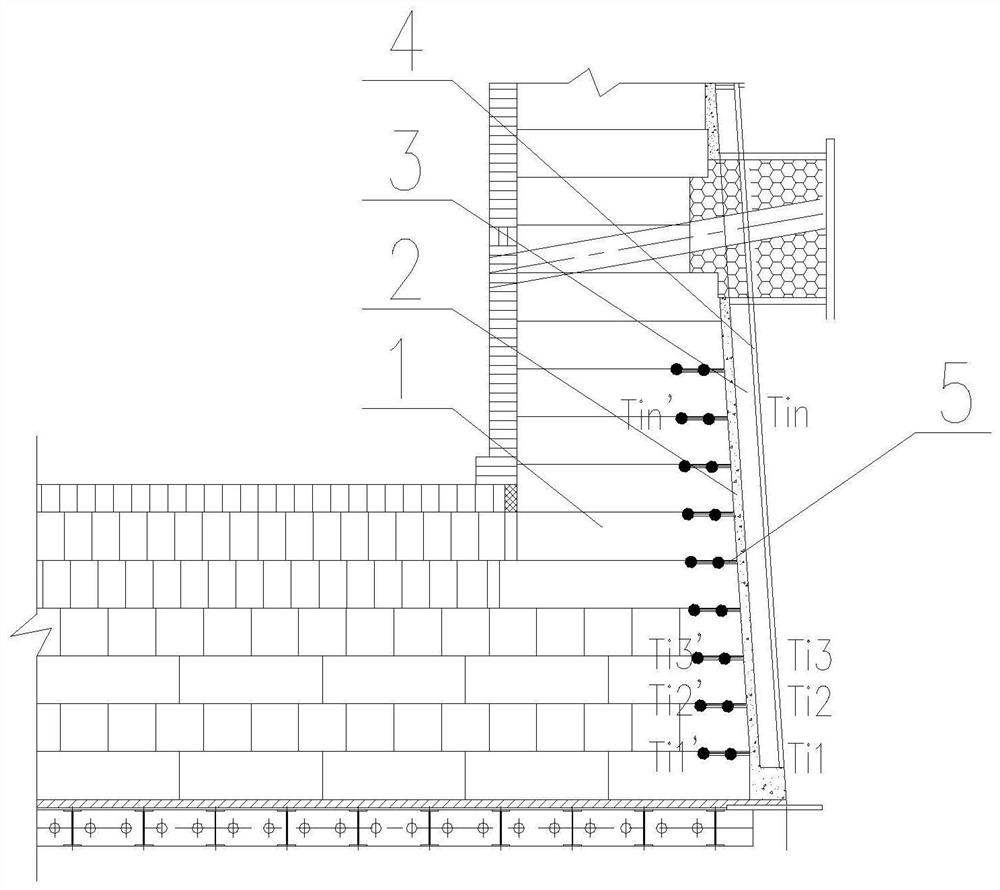

[0087] Specific embodiment: Taking a blast furnace hearth as an example, two rings of distributed optical fibers 2 are arranged in the inner ring lining 1 of each layer of the blast furnace hearth. Since the distributed optical fibers can set multiple points along the optical fiber path, for the convenience of display, each layer Only 25 optical fiber temperature measuring points are set in the inner ring lining 1 circumferential direction.

[0088] 2 layers of temperature measuring optical fibers in the circumferential direction 2 spacing L 0 =100mm, the distance L between the inner ring fiber and the cold surface of the inner lining 1 =200mm.

[0089] The thermal conductivity of the refractory lining 1 is λ=18w / m.℃;

[0090] The melting temperature of the iron layer is 1150°C;

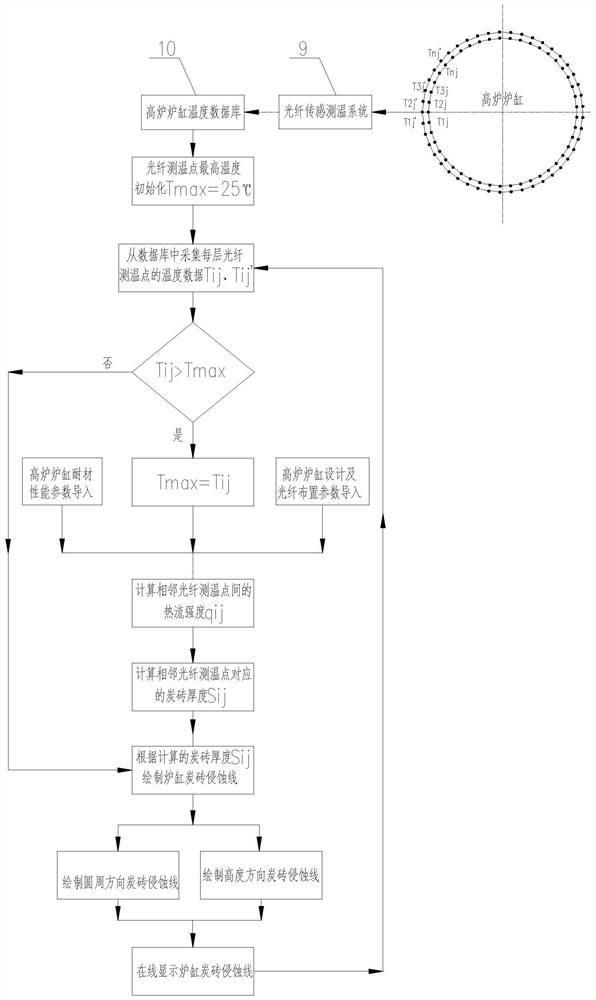

[0091] Initialize the maximum temperature T of the blast furnace hearth refractory lining max =25°C

[0092] When the temperature measurement data T of the 2-ring distributed optical fiber 2 in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com