Invisible bullet-proof material as well as preparation method and application thereof

A metamaterial, bulletproof layer technology, applied in chemical instruments and methods, armor plate structure, lamination, etc., can solve the problem of inapplicability of low-frequency radar waves, etc., to achieve the effect of ensuring bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

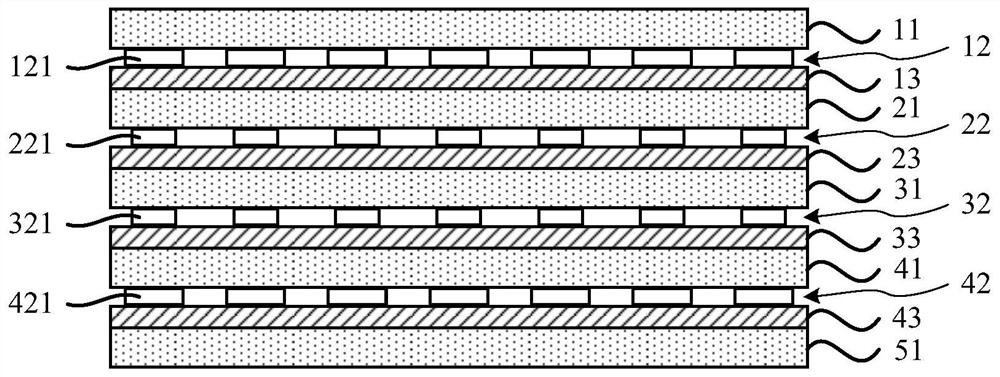

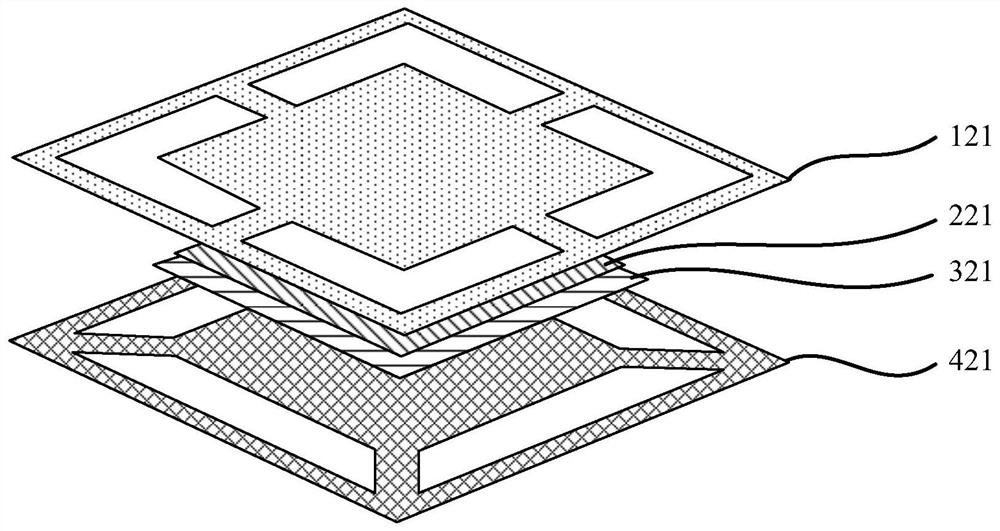

[0088] This example provides a kind of stealth bulletproof material, such as figure 1 with figure 2 As shown, it includes the first bulletproof layer 11, the first metamaterial layer 12, the first base layer 13, the second bulletproof layer 21, the second metamaterial layer 22, the second base layer 23, and the third bulletproof layer stacked in sequence. 31. The third metamaterial layer 32, the third base layer 33, the fourth bulletproof layer 41, the fourth metamaterial layer 42, the fourth base layer 43 and the fifth bulletproof layer 51;

[0089] Among them, the first bulletproof layer 11, the second bulletproof layer 21, the third bulletproof layer 31, the fourth bulletproof layer 41 and the fifth bulletproof layer 51 are all composed of UHMWPE non-weft cloth, and their thicknesses are 8mm, 7mm, 1mm, and 6mm respectively. , 5mm;

[0090] The materials of the first base layer 13, the second base layer 23, the third base layer 33 and the fourth base layer 43 are all PE f...

Embodiment 2

[0102] This example provides a kind of stealth bulletproof material, and the difference with embodiment 1 is:

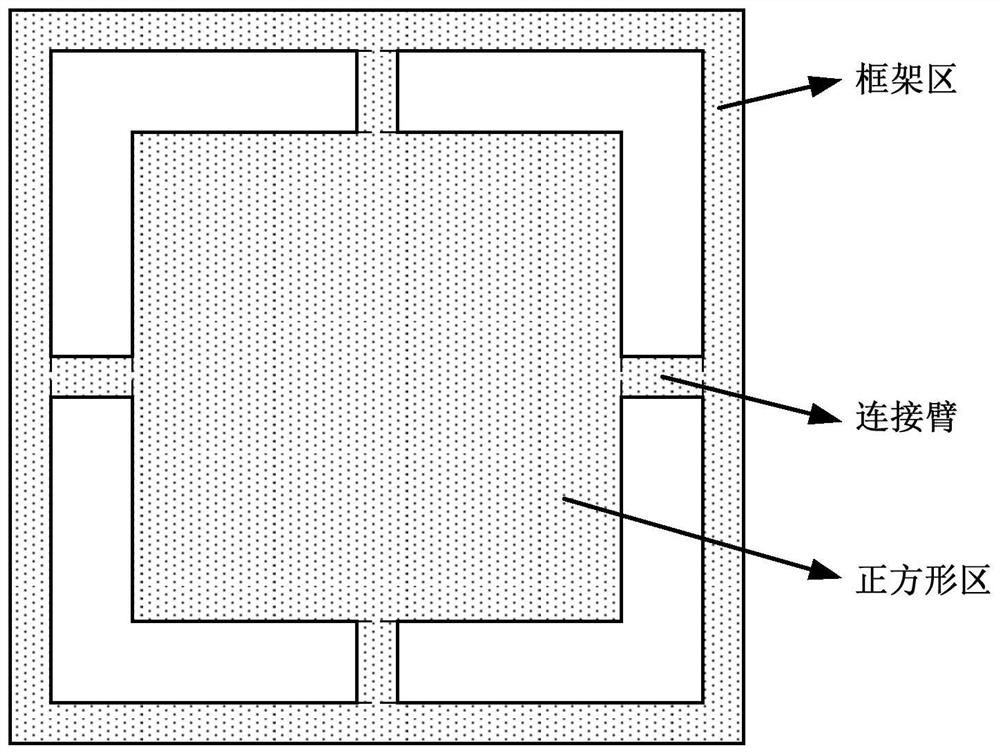

[0103] The square resistance of the first resistor sheet 121 is 150Ω, the outer contour side length of the frame area is 36mm, the inner contour side length of the frame area is 30mm, and the side length of the square area is 16mm;

[0104] The square resistance of the second resistance sheet 221 is 100Ω, and the side length is 14mm;

[0105] The square resistance of the third resistor sheet 321 is 100Ω, the side length is 16mm, and the distance between the third metamaterial layer 32 and the second metamaterial layer 22 is 1.3mm;

[0106] The square resistance of the fourth resistance sheet 421 is 50Ω, the outer contour side length of the frame area is 36 mm, the inner contour side length of the frame area is 30 mm, and the side length of the square area is 18 mm.

Embodiment 3

[0108] This example provides a kind of stealth bulletproof material, and the difference with embodiment 1 is:

[0109] The square resistance of the first resistor sheet 121 is 250Ω, the outer contour side length of the frame area is 37mm, the inner contour side length of the frame area is 32mm, and the side length of the square area is 20mm;

[0110] The square resistance of the second resistance sheet 221 is 400Ω, and the side length is 18mm;

[0111] The square resistance of the third resistance sheet 321 is 400Ω, the side length is 20mm, and the distance between the third metamaterial layer 32 and the second metamaterial layer 22 is 1.6mm;

[0112] The square resistance of the fourth resistive sheet 421 is 180Ω, the outer contour side length of the frame area is 37 mm, the inner contour side length of the frame area is 32 mm, and the side length of the square area is 20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com