Heat energy recovery and treatment system for baking seaweed products

A technology of heat energy recovery and treatment system, applied in food processing, drying, application and other directions, can solve the problems of ineffective use of oven heat energy, lack of steam recovery and utilization, low heat energy utilization efficiency, etc., to achieve acceleration speed and effect. Perfect, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

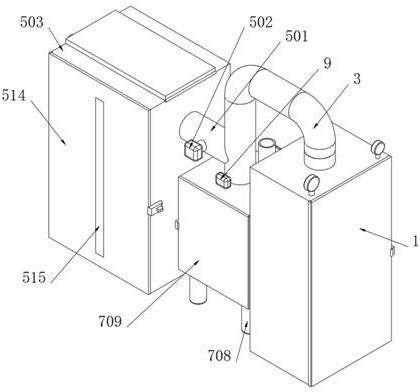

[0042] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a heat recovery and processing system for baking seaweed products, including a baking oven 1, an outlet pipe 2 is installed through the top of the oven 1, and an output pipe is installed on the top of the outlet pipe 2 through an adapter 3. An exhaust fan 4 is embedded in the inner side of the air outlet pipe 2, and the input end of the exhaust fan 4 is electrically connected to the external output end;

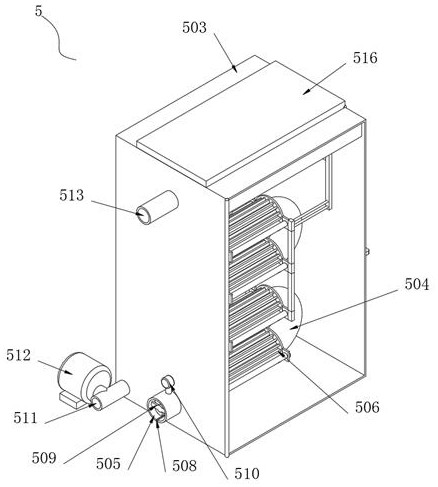

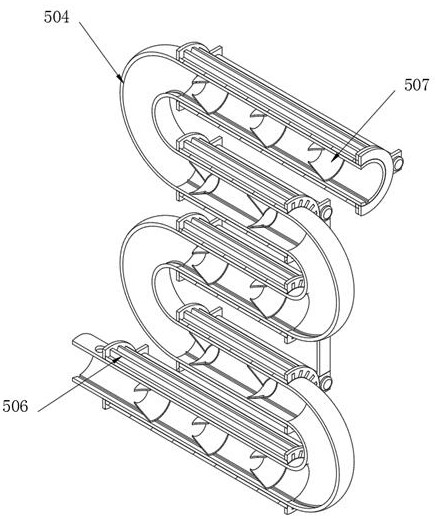

[0043] A heat exchange assembly 5 is installed on one side of the output pipe 3, and the heat exchange assembly 5 includes an exhaust pipe 501, a first limiting valve 502, a water storage tank 503, a heat exchange pipe 504, a discharge pipe 505, a heat conducting strip 506, a deceleration ring 507, Drainage tank 508, air outlet fan 509, temperature detector 510, water inlet pipe 511, booster water pump 512, water outlet pipe 513, water tank sealing door 514, observation window 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com