Blow-off valve with pressure feedback control

A technology of feedback control and blow-off valve, which is applied in the direction of safety valve, balance valve, valve device, etc., and can solve the problems of large underwater transient radiation noise and the inability of the stop valve to adjust the blow-off air supply pressure according to the blow-off requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

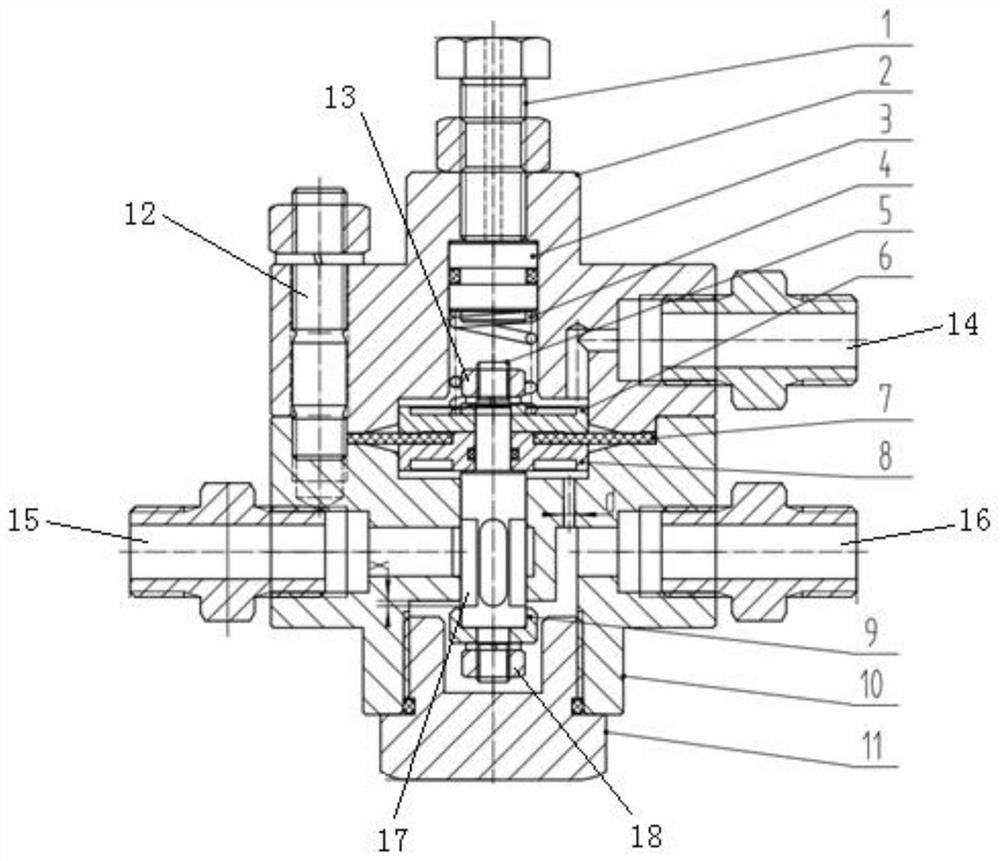

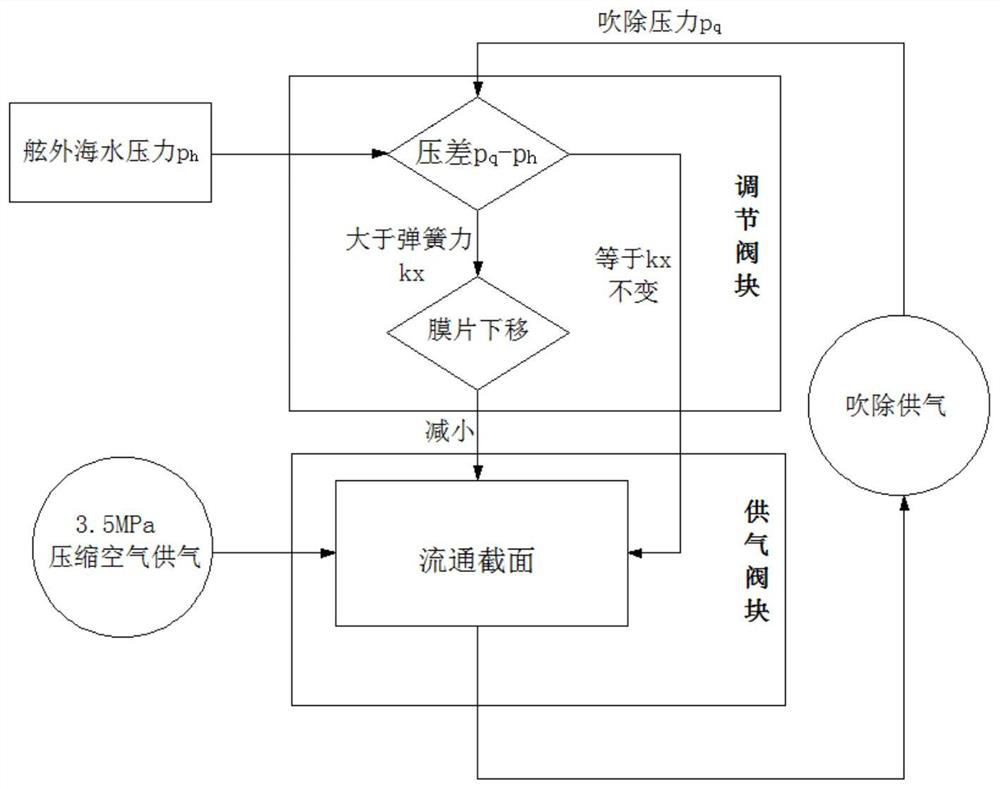

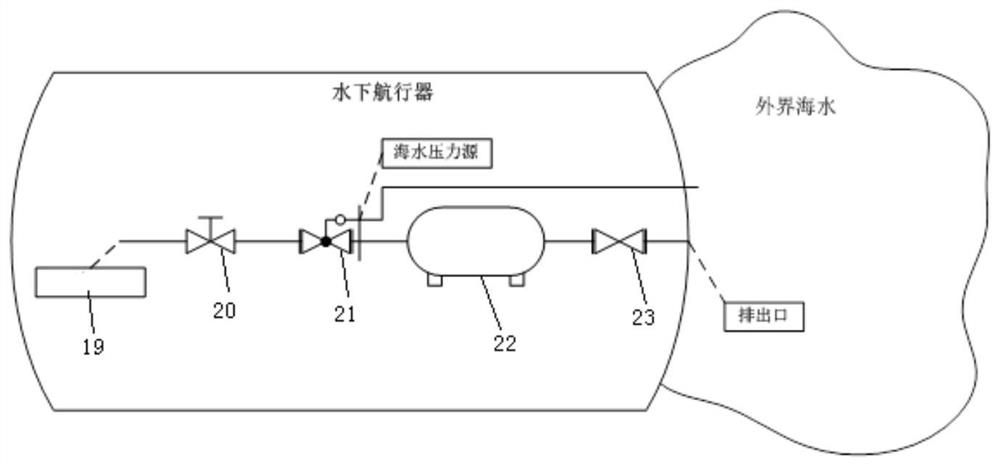

[0015] Such as figure 1 A blow-off valve 21 with pressure feedback control shown includes an upper valve body 2, a pressure regulating assembly, a lower valve body 10 connected to the upper valve body 2 through a side stud 12, and a valve core 5; The upper valve body 2 is provided with an upper valve cavity, and the side part is provided with an outboard seawater interface 14 communicating with the upper valve cavity for introducing sea water; the upper part of the valve core 5 is installed in the upper valve cavity, and the upper part of the valve core 5 is connected to the upper valve cavity The pressure regulating assembly installed between the upper and lower valve body 10 is connected, and the pressure regulating assembly pushes the valve core 5 to move axially under the action of seawat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com