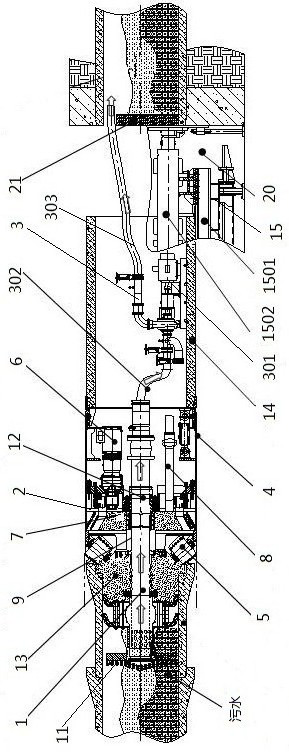

A pipeline renewal boring machine and its construction method

A technology of roadheader and pipeline, which is applied in the field of pipeline renewal roadheader and its construction, and can solve the problems of difficulty in cleaning fluid medium, elevation, interruption of operation and dredging of small pipeline lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

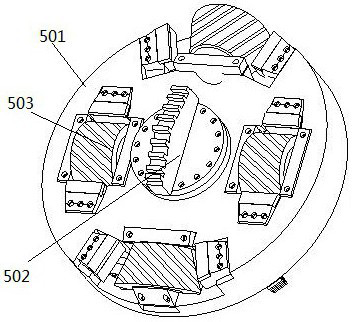

[0086] Embodiment 5: A kind of slag clearing device used for pipeline renewal roadheader, such as Figure 7~10 As shown, it includes a dredging head 11 and a power transmission shaft tube 12, the front end of the power transmission shaft tube 12 is connected with the dredging head 11, and the rear end of the power transmission shaft tube 12 is connected with the digging cutter head 5 of the tunneling main engine 2 .

[0087] Such as Figure 13 As shown, the dredging head 11 includes a leading cutter head 11-1, and the leading cutter head 11-1 includes at least two knife beams 11-1-1 arranged at equal angles, and three or more knife beams can be set as required. 4 or more, the cutter beam 11-1-1 is evenly distributed with cutters 11-1-2, the cutters can be cutters or scrapers, and the middle part of the cutter beam can be provided with a fishtail knife to improve the dredging ability. A drive shaft tube 11-2 is provided on the back side of the leading cutter head 11-1, and at...

Embodiment 6

[0090] Embodiment 6: A kind of slag-removing and ensuring-passing device for pipeline renewal roadheader, such as Figure 11 , 12 As shown, two pigs 11-3 are fixed on the drive shaft tube 11-2, the drive shaft tube 11-2 and the pigs 11-3 are coaxially arranged, and the two adjacent pigs 11-3 3 are connected by a support sleeve 11-6, and a filter plate 11-7 is provided at the front end of the pig 11-3 near the leading cutter head 11-1 to filter out larger foreign matters in the sewage. On the one hand, the filter plate and the pipe pig can isolate the sewage, prevent the surrounding soil from being polluted, and achieve the effect of sealing and isolating the second mud tank on the rear side of the pipe pig; The sewage can completely enter the internal hollow drive shaft tube from the leading cutter head at the front end of the pig, and then enter the protection circulation system through the power transmission shaft tube for sewage circulation. The power transmission shaft t...

Embodiment 7

[0093] Embodiment 7: A kind of slag clearing device used for pipeline renewal roadheader, such as Figure 14 , 15 As shown, the dredging head 11 includes a central axis tube 11-2a, and the central axis tube is hollow. The front end of the central axis pipe 11-2a is provided with a conical grille head 11-1a. The conical grille head 11-1a can not only carry out drilling and dredging of the silt, but also allow the sewage to enter the central shaft through the conical grille. Tube. Two pigs 11-3 are fixed on the central axis pipe 11-2a, the central axis pipe 11-2a and the pipe pigs 11-3 are arranged on the same axis, and pass between two adjacent pipe pigs 11-3 The support sleeve 11-6 is connected, and the front end of the pipe cleaner 11-3 near the conical grid head 11-1a is provided with a wire brush 11-7a; the wire brush and the rubber cup of the pipe cleaner can not only realize auxiliary sewage discharge function, and achieve a closed and isolated effect on the excavation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com