A sandstone reservoir engineering well pattern structure

A sandstone reservoir and engineering technology, applied in the field of sandstone reservoir engineering well pattern structure, can solve the problems of impurity entry, crude oil quality impact, injection water filtration treatment, etc.

Active Publication Date: 2022-06-03

XI'AN PETROLEUM UNIVERSITY

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention provides a sandstone reservoir engineering well pattern structure, which can effectively solve the problem that the water injection wells proposed in the above background technology do not filter the injected water when injecting water into the oil layer, so that the impurities in the injected water enter the crude oil in the formation. problems affecting the quality of crude oil

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

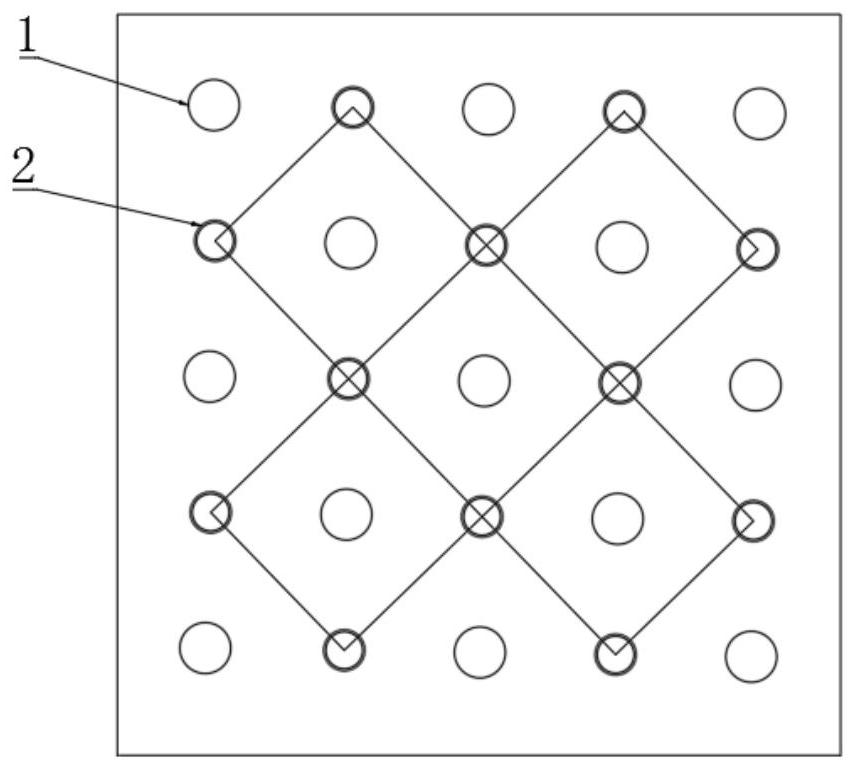

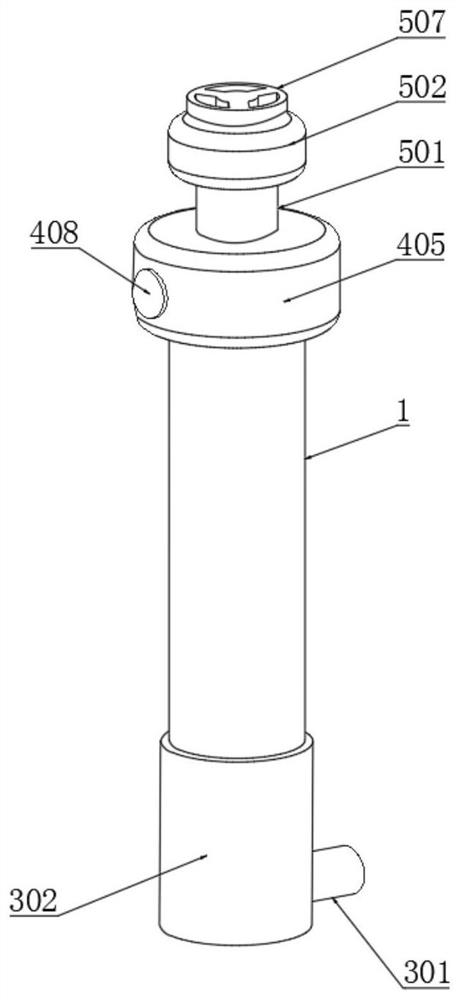

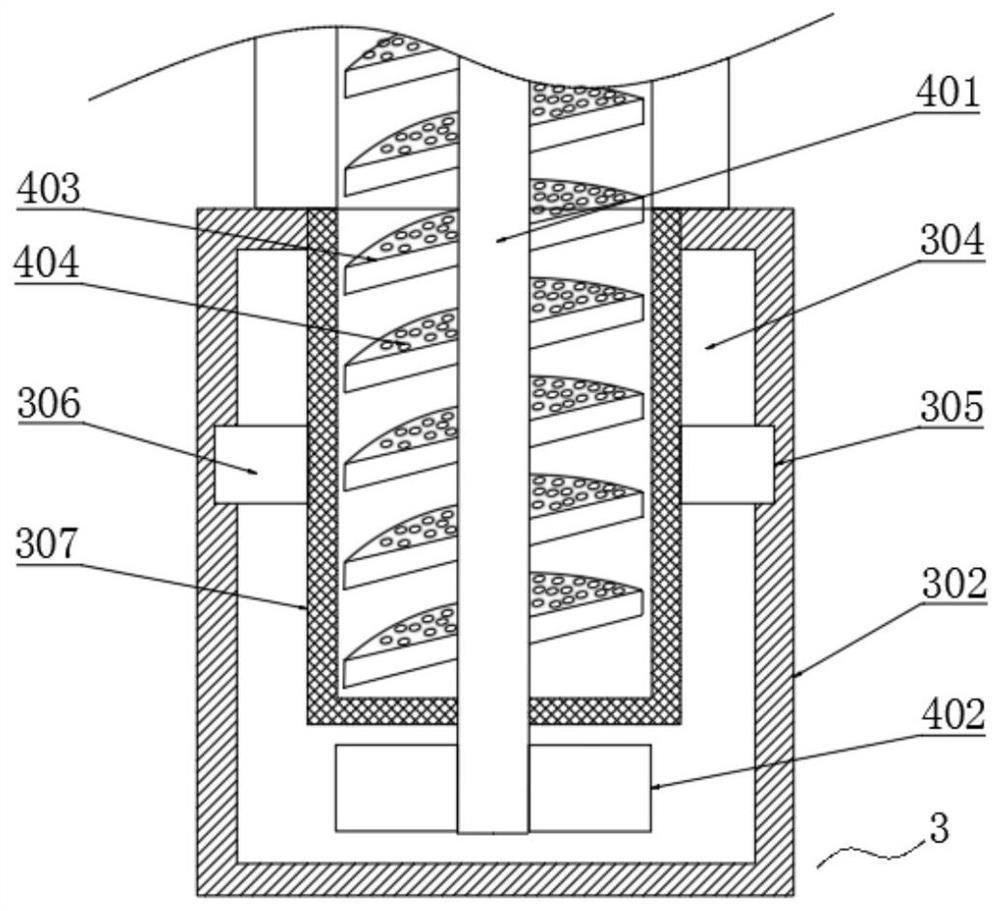

The invention discloses a sandstone oil reservoir well network structure, which includes a water injection well and an oil production well, an oil production well is arranged outside the water injection well, and a filter mechanism is fixedly connected to the bottom of the water injection well, and the filter mechanism includes a water outlet pipe, A filter cartridge, a filter chamber, a clamping slot, a block and a filter cartridge, a filter cartridge is fixedly connected to the bottom of the water injection well, and a water outlet pipe is fixedly connected to the bottom of one end of the filter cartridge, and a filter cavity is opened inside the filter cartridge The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. It is equipped with a filter mechanism, which cooperates with the water inlet pipe to transport the water, and at the same time filters the water through the filter cartridge, and stores the impurities in the water in the filter cartridge to avoid contamination in the water. Impurities enter the formation and affect the quality of crude oil in the formation. In addition, through the inclined setting of the outlet pipe, when the outlet pipe pumps out water, a tangential force is formed inside the filter cartridge, which facilitates the rotation of the water inside the filter cartridge and improves the filtering effect.

Description

A well pattern structure for sandstone reservoir engineering technical field [0001] The present invention relates to the technical field of sandstone reservoir engineering, in particular to a sandstone reservoir engineering well pattern structure. Background technique Oil is very precious as an important mineral resource, and in the oil exploitation process, in order to improve the recovery factor of oil, Usually divided into three stages: primary oil recovery, relying on the natural energy of the formation to produce oil with a recovery rate below 30%; secondary oil recovery, using injection Water and gas injection technology can supplement the energy of the reservoir to produce oil, and the recovery factor can be increased to 40-50%; The recovery rate can be increased to about 80-85% by strengthening the recovery of the remaining reserves by means of physics, etc. At present, many oil fields have entered the secondary recovery process. In the oil stage, water flood...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21B43/30E21B43/20C02F9/04C10G31/09C02F103/10

CPCE21B43/30E21B43/20C02F1/001C02F1/50C10G31/09C02F2103/10C10G2300/1033Y02A20/00

Inventor 李留仁

Owner XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com