Flexible rope tension-displacement measurement and control and crimping equipment

A crimping equipment and rope technology, which is applied in the field of tension-displacement measurement and control and crimping equipment, can solve the problems of rope tension influence, heavy workload, and large span of elastic modulus range, so as to improve measurement accuracy and high precision , Increase the effect of production precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A tension-displacement measurement and control and crimping device for a flexible rope proposed by the present invention will be further described in detail below with reference to the drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims.

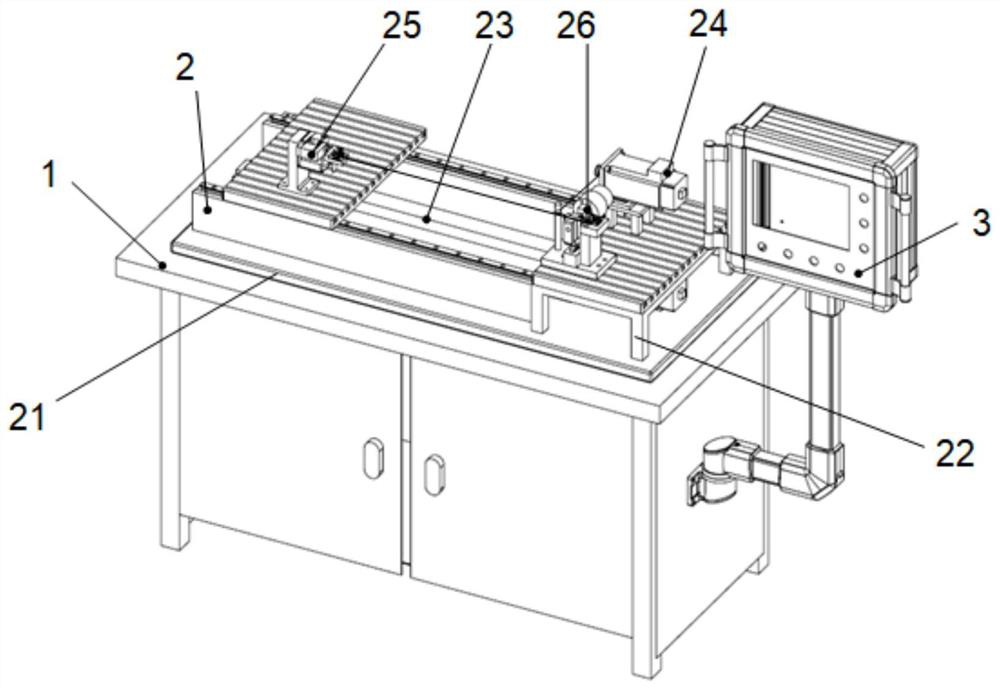

[0040] see Figure 1 to Figure 6 As shown, the present invention provides a tension-displacement measurement and control and crimping equipment for flexible ropes, including a machine base 1, a rope connection device 2 and a human-computer interaction control box 3, and the rope connection device 2 is fixedly installed on the machine base 1, The human-computer interaction control box 3 is installed on the side of the base;

[0041] The base 1 is placed horizontally on the ground and is used to install the modular components of the entire device;

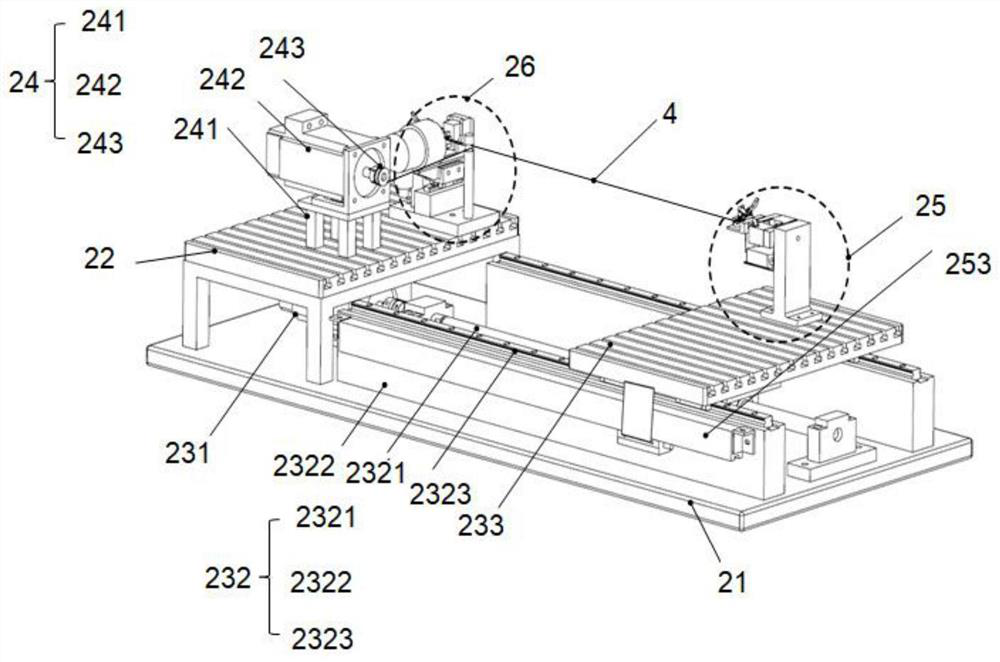

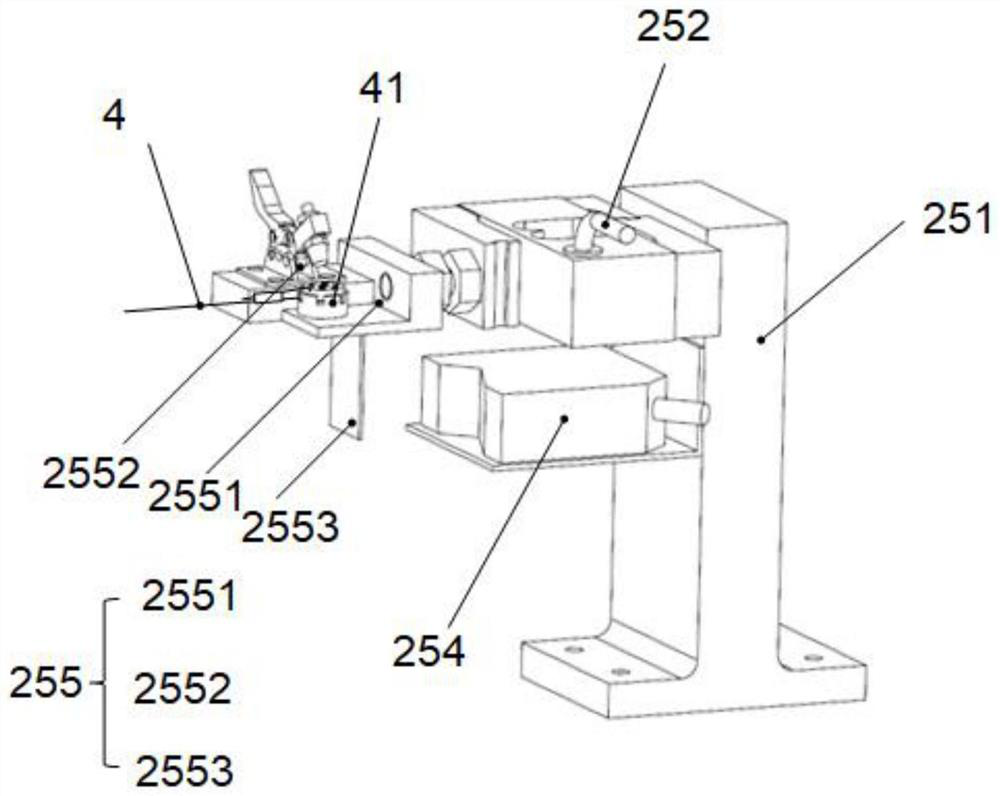

[0042] see figure 2 As shown, the rope connection device 2 includes a base plate 21, a fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com