Online balancing device and method for stranding machine

A technology of balancing device and stranding machine, which is used in measuring devices, auxiliary devices for rope making, static/dynamic balance testing, etc. Quality assurance, the effect of eliminating the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

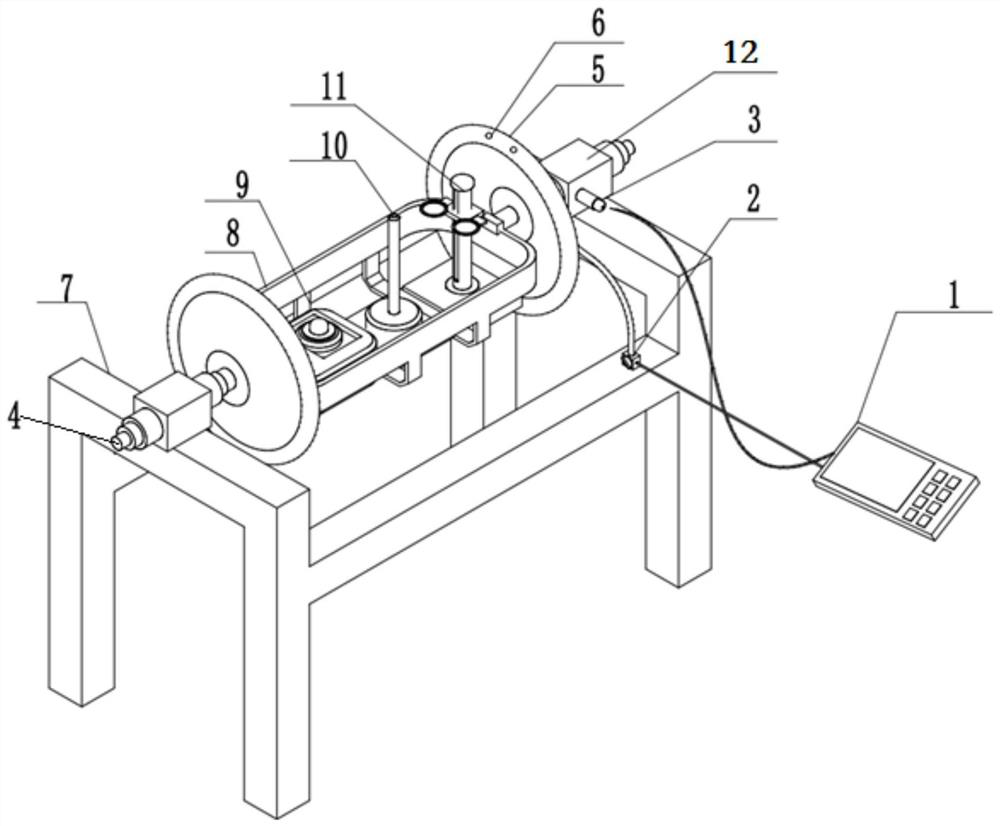

[0028] Such as Figure 1 to Figure 2 Shown, a kind of stranding machine online calibration balance device, comprises stranding machine and portable dynamic balancer;

[0029] Described stranding machine comprises main frame 7, main shaft 4, flywheel disc 5, cradle 8, reduction box 9, cable arrangement 10, take-up line 11, main shaft seat 12; Installed on the cradle 8 in turn from left to right, the flywheel disc 5 is assembled on the main shaft 4 with the central axis to form a main shaft flywheel rotation mechanism; the two main shaft flywheel rotation mechanisms are symmetrically installed on both sides of the cradle 8, and the first end of the main shaft 4 Connect with one side of the cradle 8 through the first bearing, the second end of the main shaft 4 is installed on the main shaft seat 12 through the second bearing, the second end of the main shaft is used to connect the driving mechanism, and the main shaft seat 12 is fixed on the main frame 7 superior;

[0030] The ...

Embodiment 2

[0038] A method for on-line calibration and balance of a stranding machine, using the above-mentioned online calibration and balance device for a stranding machine;

[0039] When the running speed of the main shaft 4 and the flywheel disc 5 reaches 3000rpm, the dynamic balance display 1 displays the measurement results, and obtains the angle and weight of the counterweight;

[0040] According to the measurement result displayed by the dynamic balance display 1, the arc-shaped counterweight plate 6 of the corresponding weight is arranged on the flywheel disc 5 on the same side at a corresponding angle;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com