Semiconductor-grade straight-pull re-feeding cylinder

A technology of semiconductor and body, applied in the field of semiconductor-grade Czochralski casting cylinder, can solve the problems of polluted silicon material life, silicon splashing, etc., and achieve the effects of reducing production cost, improving quality, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

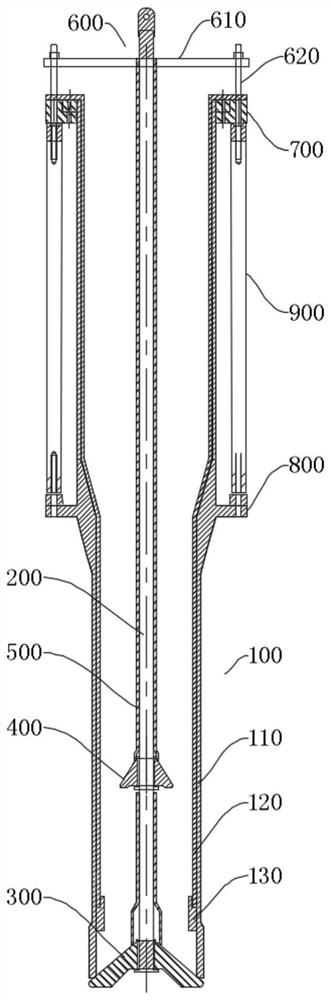

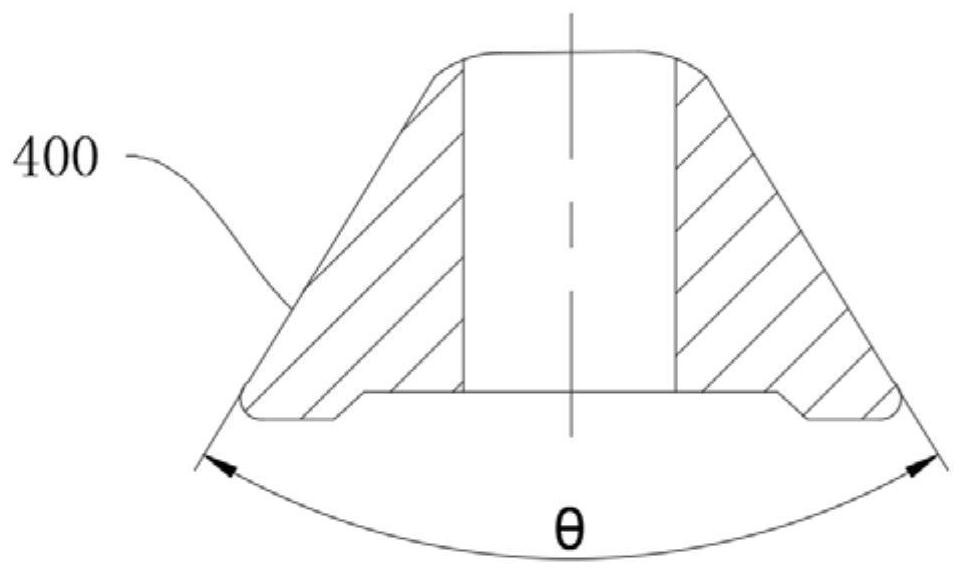

[0030] This embodiment proposes a semiconductor-grade CZ compound throwing cylinder, such as figure 1 As shown, the cylinder body 100, the molybdenum rod 200 and the main quartz umbrella 300 arranged at the lower end of the cylinder body 100 are included. There is also a quartz cylinder 500 for isolating the molybdenum rod 200 and the silicon material and passing through the auxiliary quartz umbrella 400; the upper end of the cylinder body 100 is provided with a positioning assembly 600 for adjusting the lifting positions of the main quartz umbrella 300 and the auxiliary quartz umbrella 400.

[0031] Specifically, the cylinder body 100 is a double-layer structure, including an outer cylinder 110 and an inner cylinder 120 adapted to the inner wall of the outer cylinder 110, and both the outer cylinder 110 and the inner cylinder 120 are cylinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com