Electroplating equipment capable of reducing edge effect and working method of electroplating equipment

An electroplating equipment and edge effect technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve problems affecting the quality of the coating, and achieve the effects of avoiding coating peeling, increasing turbulence, and precise displacement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

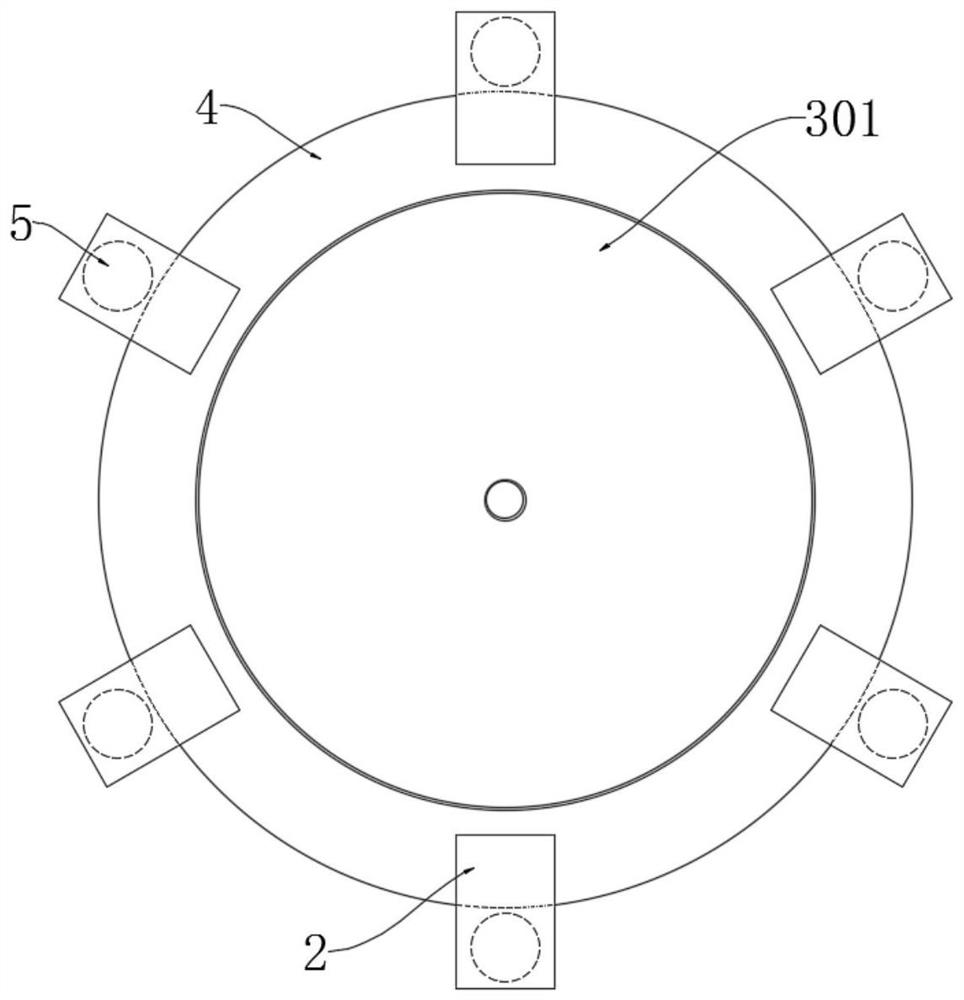

[0029] refer to Figure 1-5 , a working method of electroplating equipment that can reduce edge effects, the specific use method is as follows:

[0030] S1. Clamping workpieces: fix the workpieces on multiple hangers 5 respectively, so that the workpieces are distributed as evenly as possible, and uneven distribution of workpieces may lead to inconsistent thickness of the coating;

[0031] S2. Replenishing electrolyte: observe the liquid level of the electrolyte in the plating tank 1, replenish the electrolyte to make it reach the standard height, then turn on the control switch, and observe whether the equipment can work normally;

[0032] S3, electroplating: start to electroplate the workpiece, remove the workpiece after the electroplating is completed, and prepare for electroplating of the next batch of workpieces;

[0033] The above-mentioned electroplating equipment that can reduce the edge effect also involves a kind of electroplating equipment during use, including a p...

Embodiment 2

[0042] refer to Image 6 The difference between this embodiment and Embodiment 1 is that: the upper surface of the positioning plate 4 is provided with an annular groove, and a plurality of sliding seats 9 are slidably arranged in the annular groove, and the sliding seats 9 can rotate freely along the annular groove, and each fixed Seats 2 are mounted on the upper ends of corresponding sliding seats 9, and solenoids 10 are arranged in each sliding seat 9, and electrorheological fluid is filled in the annular groove.

[0043] During specific work, when the sizes of the workpieces are different, if the arrangement of the fixed hangers 5 is still followed, the distance between the larger workpieces and the adjacent workpieces will be relatively close, and even the workpieces will overlap each other, which will affect the quality of the coating. , so the current can be passed into the solenoid 10 through the control device, so that two adjacent solenoids 10 repel or attract each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com