Engine cylinder liner

A technology for engine cylinders and cylinder liners, which is applied in heat treatment equipment, furnaces, quenching devices, etc., can solve problems such as the adverse effects of peripheral rings, high coolant surface temperature, and poor cooling rate, so as to avoid cylinder liner erosion and environmental pollution , Improve the effect of quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

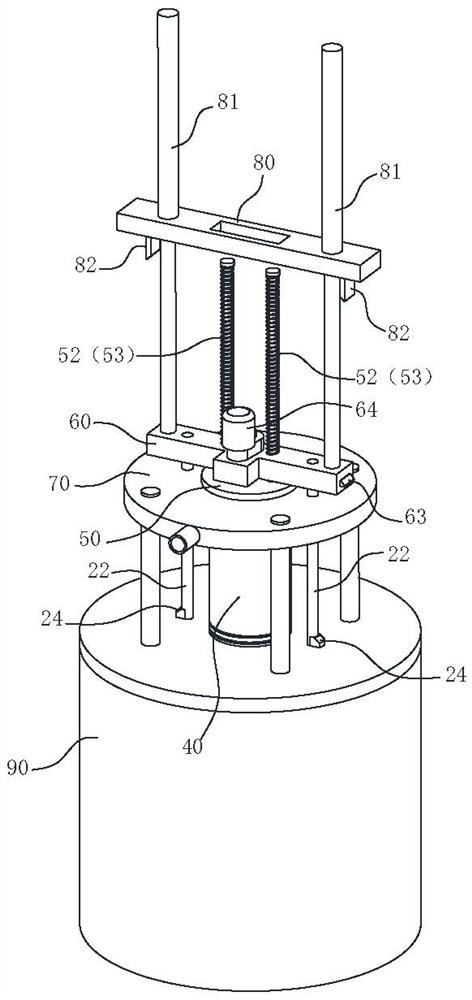

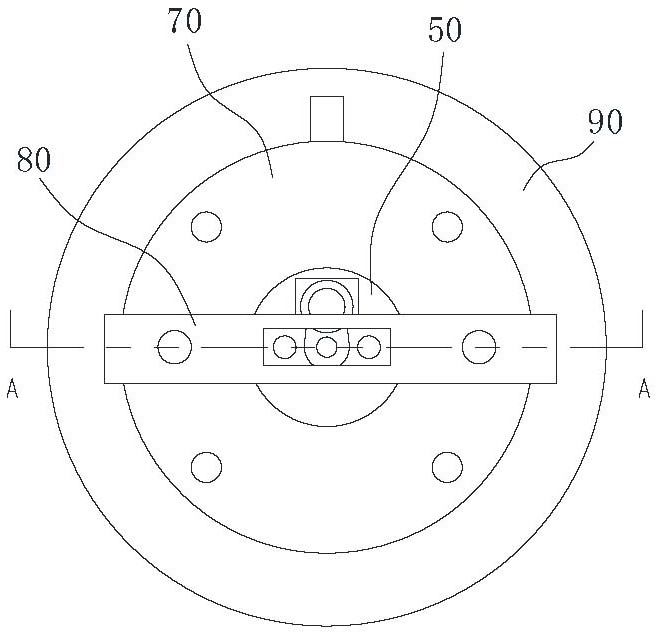

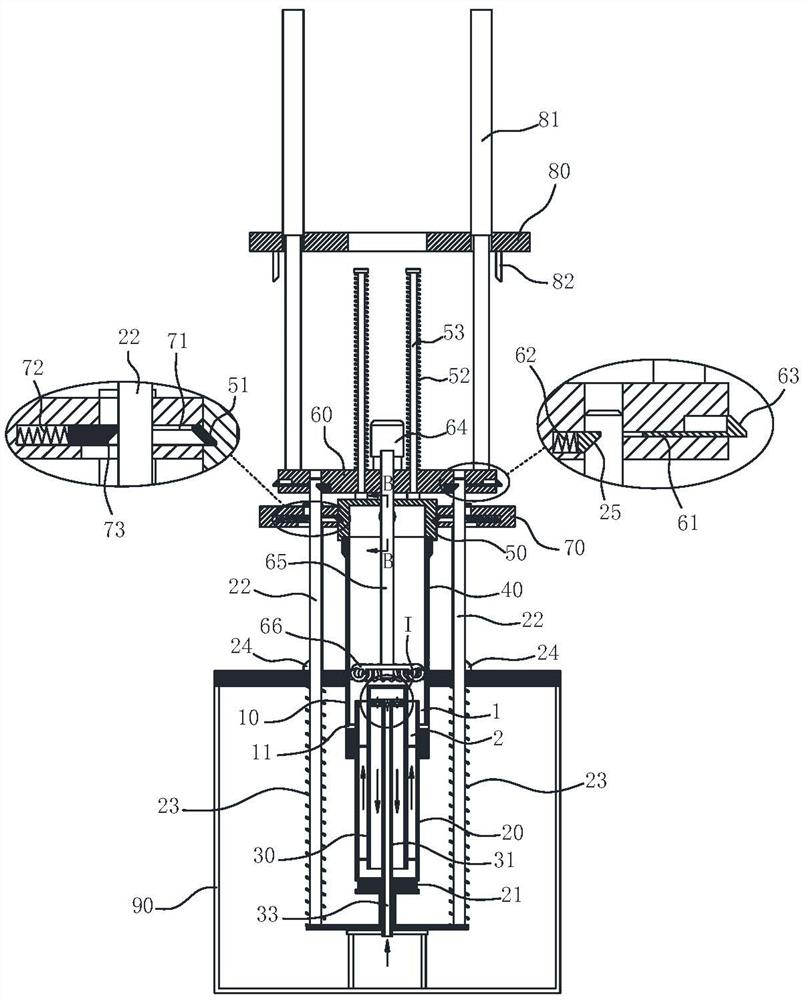

[0029] Such as figure 1 , 2, 3, an engine cylinder liner quenching system, including a first flow channel 1 and a second flow channel 2 arranged in the vertical direction, the first flow channel 1 is annular, and the second flow channel 2 is located in the first flow channel 1 Inside, the lower end of the first flow channel 1 is provided with a liquid outlet, the lower end of the second flow channel 2 is provided with a liquid inlet button, the upper ends of the first flow channel 1 and the second flow channel 2 are connected to each other, and the cylinder liner 40 forms the outer wall or Part of the outer wall, there is a common wall between the first flow channel 1 and the second flow channel 2, and the common wall is reciprocatingly arranged along the vertical direction; it also includes a heating device 66 arranged vertically reciprocatingly along the inner wall of the cylinder liner 40; the present invention During quenching, the common wall is lifted synchronously with...

Embodiment 2

[0039] A kind of engine cylinder liner, adopts following method to make:

[0040] Step 1: casting cylinder liner 40 blanks with a centrifugal casting machine;

[0041] Step 2: Machining the cylinder liner 40 blank to obtain the cylinder liner 40;

[0042] Step 3: Quenching the inner wall of the cylinder liner 40, the quenching operation is performed using the engine cylinder liner quenching system described in Embodiment 1. When quenching, first place the cylinder liner 40 on the barrel-shaped base 10, and then press it tightly with the gland 50 At the top of the cylinder liner 40, insert the heating device 66 into the bottom of the cylinder liner 40; then the heating device 66 starts to heat the inner wall of the cylinder liner 40, and the heating device 66 lifts up while heating, and at the same time, the coolant flows from the second flow channel 2 It is sent to the top of the first flow channel 1, and the common wall between the second flow channel 2 and the first flow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com