Degradation process of akebia trifoliata peel pectin

A technology of Akebia clover and peel, applied in the biological field, can solve the problems of low degradation efficiency, low yield of oligosaccharides, large molecular weight, etc., and achieve the effects of precise degradation, mass production, and change of bubble content and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A degradation process of Akebia trifoliate peel pectin, comprising the steps of:

[0032] (1) Hydrolysis treatment:

[0033] Put the peel pectin into the acid solution for acid hydrolysis treatment, the hydrolysis time is controlled to 5h, and the acid hydrolyzate is obtained after completion; the acid solution is a phosphoric acid solution with a concentration of 1mol / L, and the peel pectin is put into The weight ratio of the two corresponding to the acid solution is 1:95; the temperature of the acid solution is always kept at 70°C during the acid hydrolysis treatment;

[0034] (2) Ventilation treatment:

[0035] Into the acid hydrolyzate of step (1) gained, pass into compound gas, the duration of control feeding is 6h; Described compound gas is to be formed by mixing oxygen and argon correspondingly according to the volume ratio of 2:1;

[0036] (3) Ultrasonic treatment:

[0037] Submerge the probe of the ultrasonic instrument in the acid hydrolyzate after step (2)...

Embodiment 2

[0043] A degradation process of Akebia trifoliate peel pectin, comprising the steps of:

[0044] (1) Hydrolysis treatment:

[0045] Put the peel pectin into the acid solution for acid hydrolysis treatment, the hydrolysis time is controlled to 5.5h, and the acid hydrolyzate is obtained after completion; the acid solution is a phosphoric acid solution with a concentration of 1.3mol / L, and the peel pectin When put into the acid solution, the corresponding weight ratio of the two is 1:98; during the acid hydrolysis treatment, the temperature of the acid solution is always kept at 74°C;

[0046] (2) Ventilation treatment:

[0047] Pass into compound gas in the acid hydrolyzate of step (1) gained, the duration of control feeding is 7h; Described compound gas is to be formed by mixing oxygen and argon correspondingly according to volume ratio 2.6:1;

[0048] (3) Ultrasonic treatment:

[0049] Submerge the probe of the ultrasonic instrument in the acid hydrolyzed solution after ste...

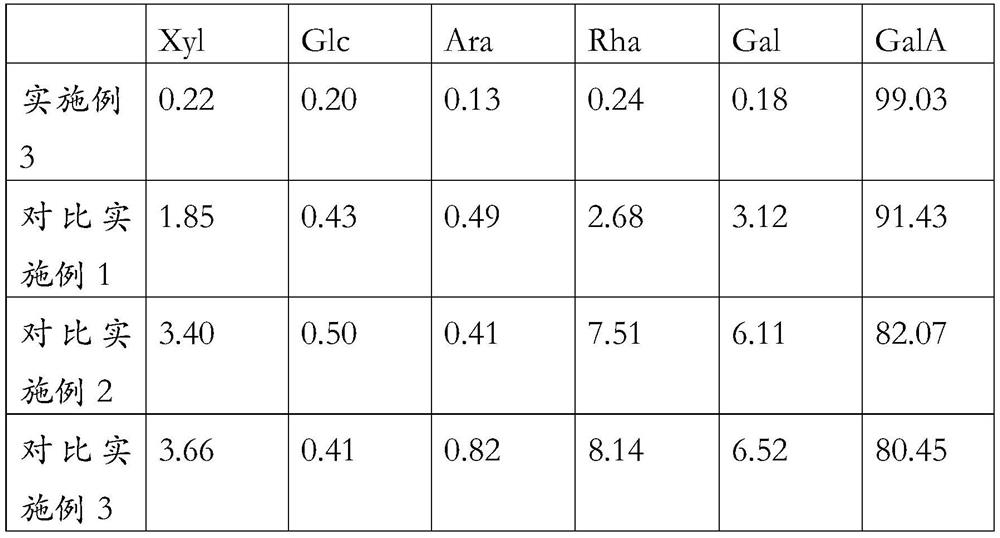

Embodiment 3

[0055] A degradation process of Akebia trifoliate peel pectin, comprising the steps of:

[0056] (1) Hydrolysis treatment:

[0057] Put the peel pectin into the acid solution for acid hydrolysis treatment, the hydrolysis time is controlled to 6h, and the acid hydrolyzate is obtained after completion; the acid solution is a phosphoric acid solution with a concentration of 1.5mol / L, and the peel pectin is put into The weight ratio of the two corresponding to the acid solution is 1:100; the temperature of the acid solution is always kept at 75°C during the acid hydrolysis treatment;

[0058] (2) Ventilation treatment:

[0059] In the acid hydrolyzate obtained in step (1), pass into composite gas, and the time length of control feeding is 8h; Described composite gas is to be formed by mixing oxygen and argon correspondingly according to the volume ratio of 3:1;

[0060] (3) Ultrasonic treatment:

[0061] Submerge the probe of the ultrasonic instrument in the acid hydrolyzed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com