Regenerant for milling material regeneration thin layer and preparation method and application thereof

A technology of regeneration agent and milling material, which is applied in the direction of building insulation materials, building components, buildings, etc., and can solve the problems of secondary aging, recycled asphalt and mixture performance that cannot meet the requirements of thin-layer overlays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

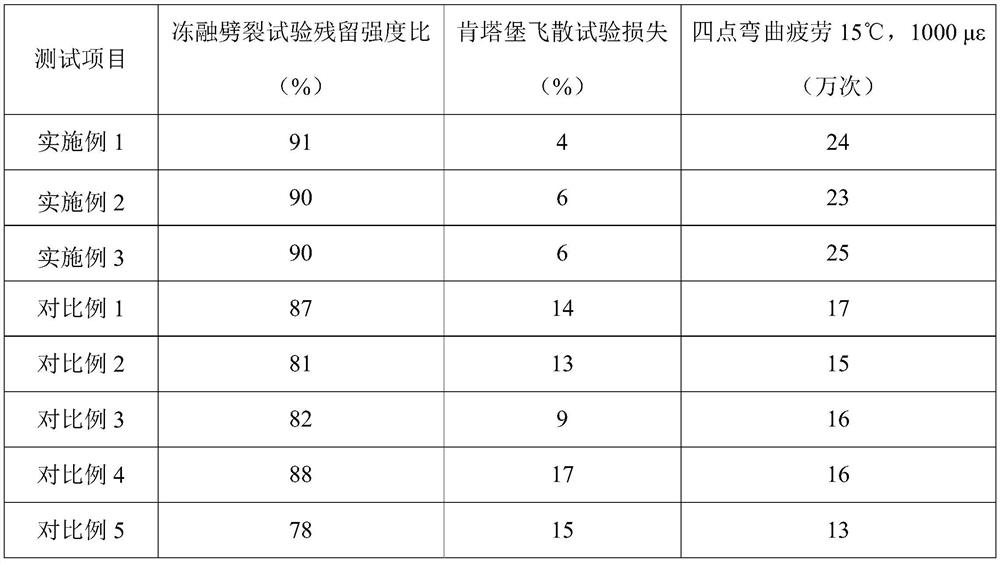

Examples

Embodiment 1

[0028] The regeneration agent for the milling material regeneration thin layer of the present embodiment is composed of the following proportions: 100 parts of asphalt, 6 parts of styrene-ethylene / butylene-styrene copolymer, 4 parts of polycarbonate diol, fatty alcohol polyoxyethylene 1.5 parts of sodium ether sulfate, 80 parts of rubber oil.

[0029] Add styrene-ethylene / butylene-styrene copolymer to the asphalt at 170°C according to the above ratio, and after stirring for 60 minutes, add polycarbonate diol, fatty alcohol polyoxyethylene ether sodium sulfate, and rubber oil according to the above ratio and stir After 40 minutes, the regeneration agent for the regeneration thin layer of the milling material was obtained.

[0030] 50 parts by mass of regenerated agent and 50 parts by mass of old asphalt were stirred at 120°C for 60 seconds to obtain regenerated asphalt. The technical indicators are shown in Table 1.

[0031] The regenerant is directly added to the milling mate...

Embodiment 2

[0033] The regeneration agent for the milling material regeneration thin layer of the present embodiment is composed of the following proportions: 100 parts of asphalt, 3 parts of styrene-ethylene / butylene-styrene copolymer, 2 parts of polycarbonate diol, fatty alcohol polyoxyethylene 0.5 part of sodium ether sulfate, 50 parts of rubber oil.

[0034] Add styrene-ethylene / butylene-styrene copolymer to the asphalt at 170°C according to the above ratio, and after stirring for 60 minutes, add polycarbonate diol, fatty alcohol polyoxyethylene ether sodium sulfate, and rubber oil according to the above ratio and stir After 40 minutes, the regeneration agent for the regeneration thin layer of the milling material was obtained.

[0035] 50 parts by mass of regenerated agent and 50 parts by mass of old asphalt were stirred at 120°C for 60 seconds to obtain regenerated asphalt. The technical indicators are shown in Table 1.

[0036] The regenerant is directly added into the milling mat...

Embodiment 3

[0039] The regeneration agent for the milling material regeneration thin layer of the present embodiment is composed of the following proportions: 100 parts of asphalt, 8 parts of styrene-ethylene / butylene-styrene copolymer, 5 parts of polycarbonate diol, fatty alcohol polyoxyethylene 2 parts of sodium ether sulfate, 100 parts of rubber oil.

[0040]Add styrene-ethylene / butylene-styrene copolymer to the asphalt at 170°C according to the above ratio, and after stirring for 60 minutes, add polycarbonate diol, fatty alcohol polyoxyethylene ether sodium sulfate, and rubber oil according to the above ratio and stir After 40 minutes, the regeneration agent for the regeneration thin layer of the milling material was obtained.

[0041] 50 parts by mass of regenerated agent and 50 parts by mass of old asphalt were stirred at 120°C for 60 seconds to obtain regenerated asphalt. The technical indicators are shown in Table 1.

[0042] The regenerant is directly added to the milling materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com