Five-axis linage automatic grouping device

A five-axis linkage and automatic technology, applied in the field of palletizers, can solve the problems of different gripping positions of the grippers and inability to locate materials, and achieve the effect of occupying less space, improving work efficiency and high space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

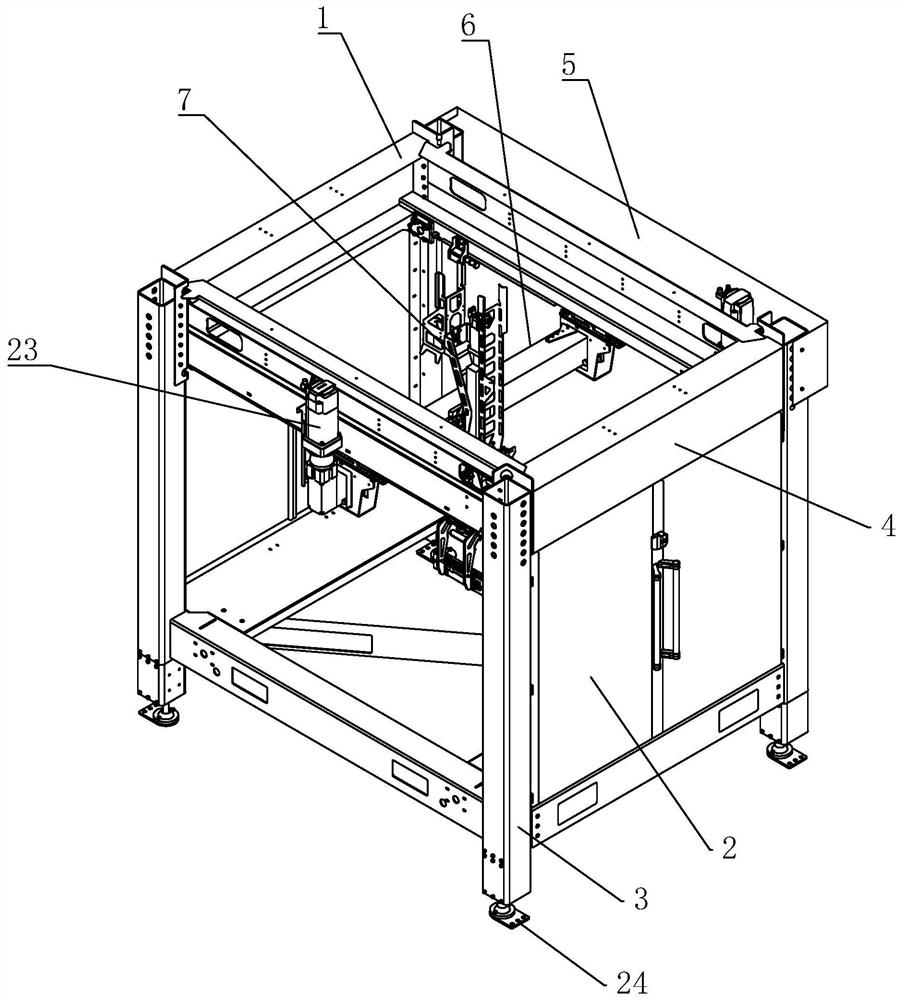

[0034] A five-axis linkage automatic marshalling device, including a square frame, the square frame includes a square upper frame 1 and a lower frame, the four corners of the upper frame 1 and the lower frame are respectively provided with uprights 3 placed on the ground through a mounting plate, The four uprights 3 are all provided with an anchor plate 24 adsorbed on the ground to fix the uprights 3 and prevent the device from shaking.

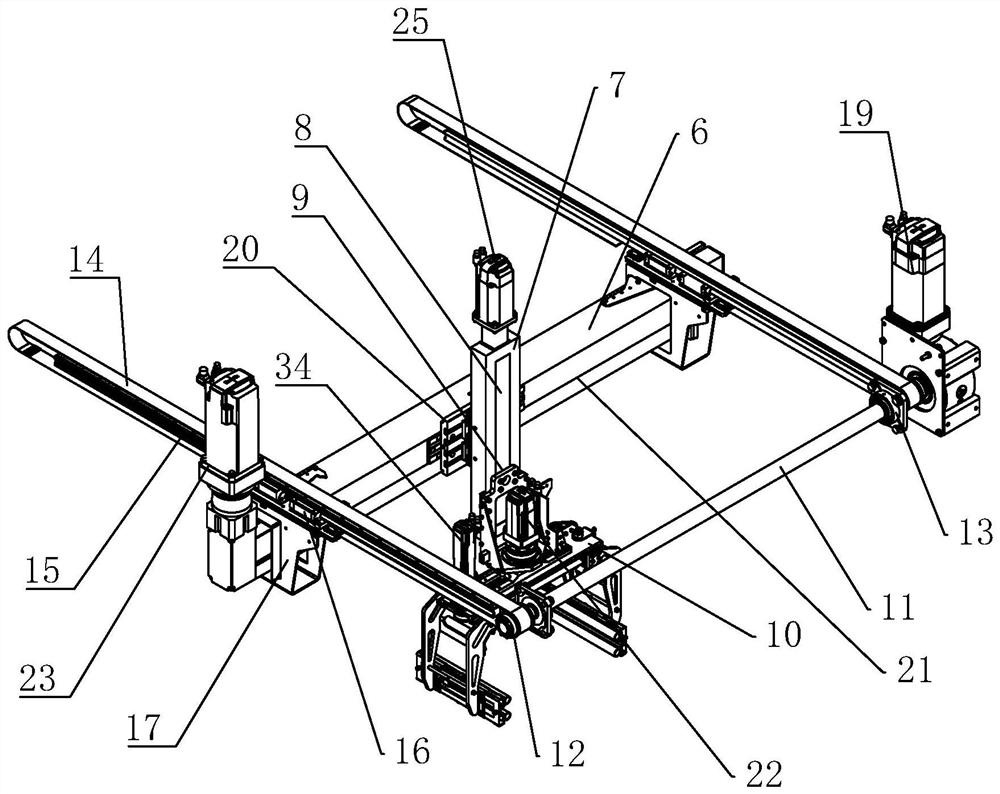

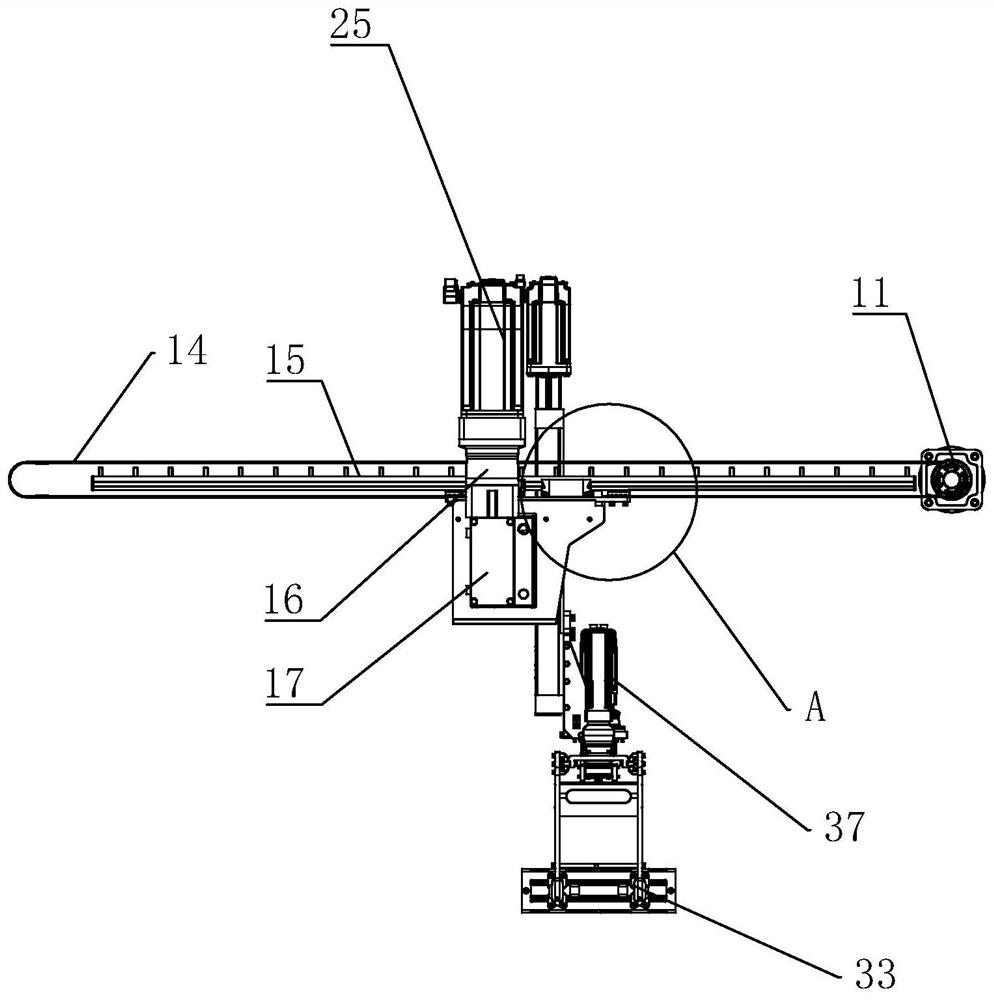

[0035] The upper frame 1 includes two outer frame groups, and the two outer frame groups respectively include two first outer frames 4 parallel to each other and two second outer frames 5 parallel to each other. The X-axis outer frame 6, the two second outer frames 5 are respectively provided with the X-axis outer frame 6 between them, and the second outer frame 5 is provided with a driving X-axis outer frame 6 between the two second outer frames 5 The driving parts that move between, the X-axis outer frame 6 is provided with a Y-axis outer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com