Automobile windshield flexible assembly system and method

A windshield, flexible assembly technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve problems affecting shooting stability, visual shooting quality interference, debugging troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

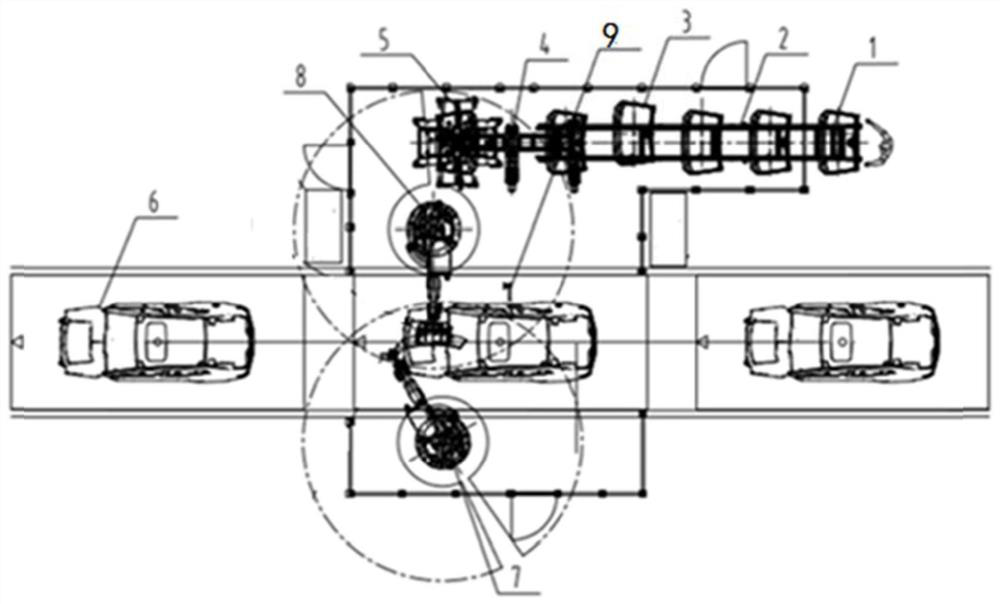

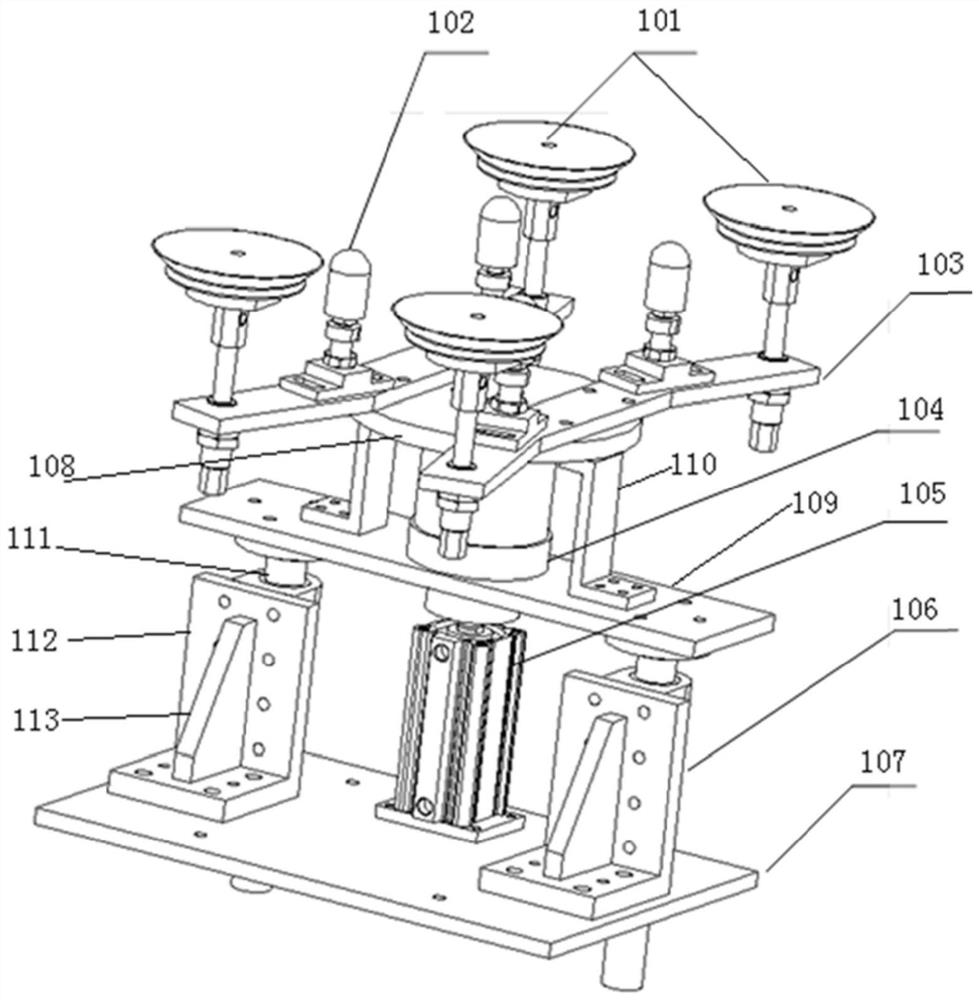

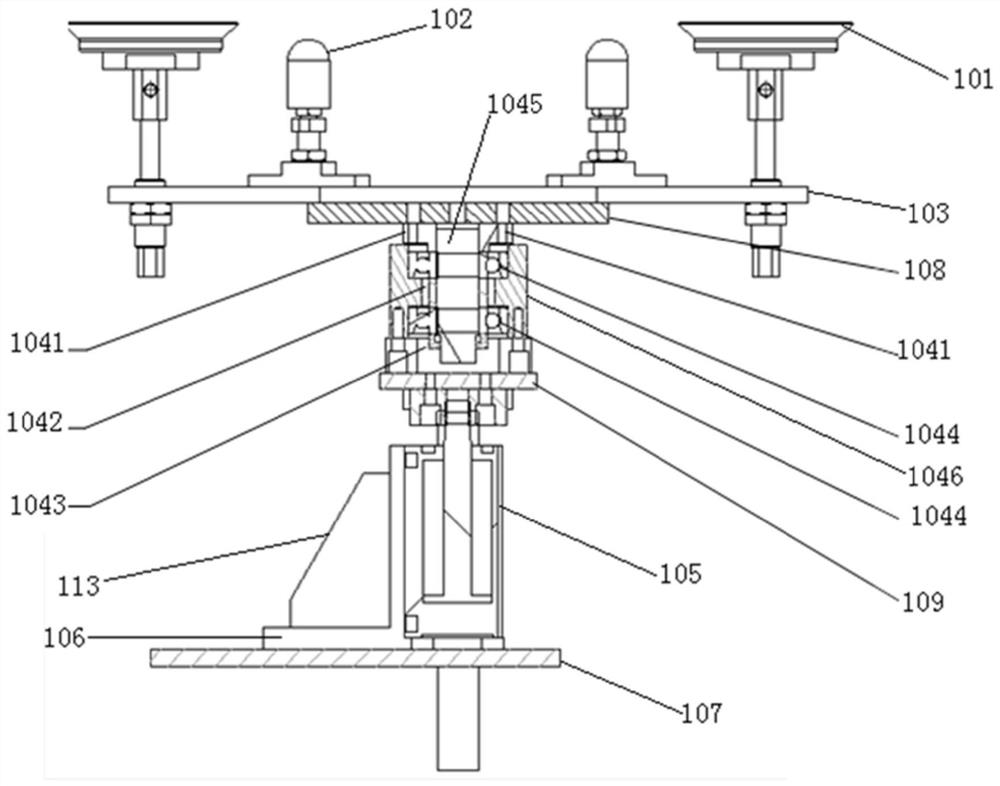

[0051] like figure 1 , the assembly system of the present invention includes a jacking and turning device 1, which is arranged at the feeding end of the glass conveying device 2 ( figure 1 the right end); the worker places the windshield on the jacking and turning device 1, and the jacking and turning device rises, and the suction cup fixes the glass for manual priming and other work. After completion, the worker presses the switch (it can be set on the jacking and turning device, or on the ground or on the conveying device, the switch can be a button, or a foot switch, etc., the switch and the controller (PLC control system) electrical connection, when the worker presses the switch, the controller receives the level signal and sends out the signal that the gluing command is completed), the jacking and turning device 1 descends to put the glass 3 on the glass conveying device, and the conveying line conveys the glass to the turning device 4. The suction cup on the turning dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com