Pigment blending device for art pattern design

A pattern design and pigment technology, applied to mixers with rotating stirring devices, decorative arts, transportation and packaging, etc., can solve the problems of increased time spent, precise control of difficult pigments, increased energy consumption, etc., and shorten the mixing time , reduce energy consumption, reduce the effect of pigment agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

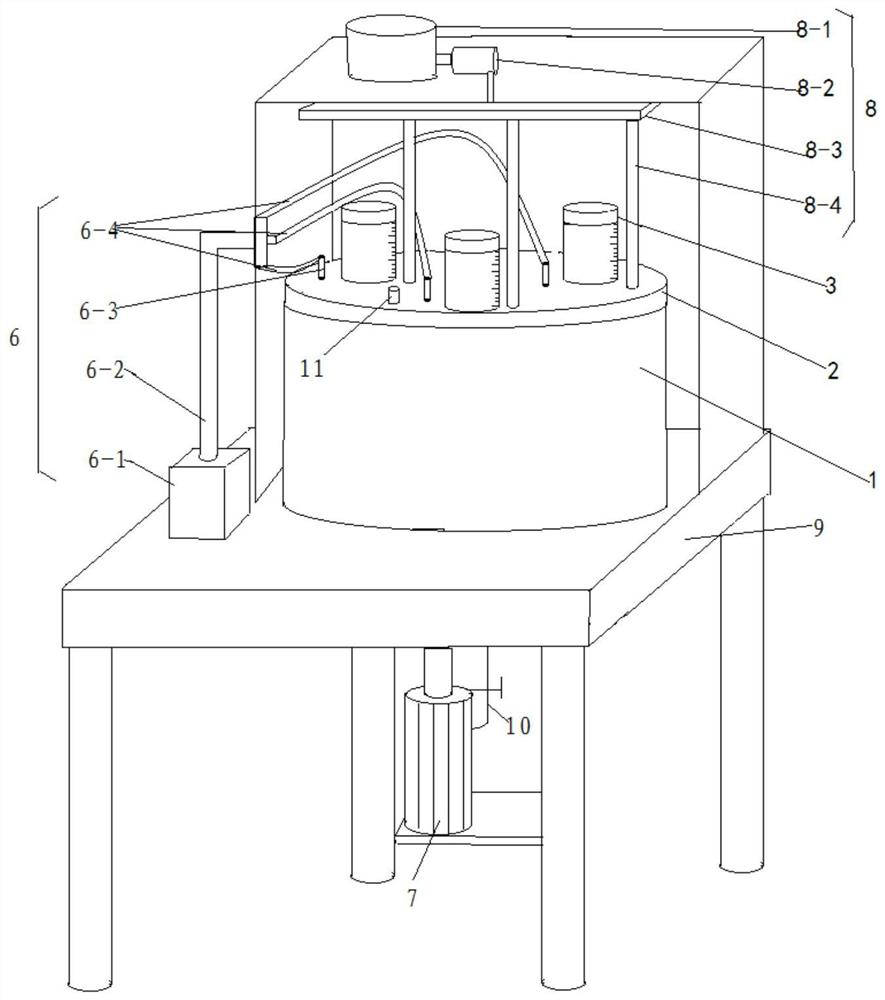

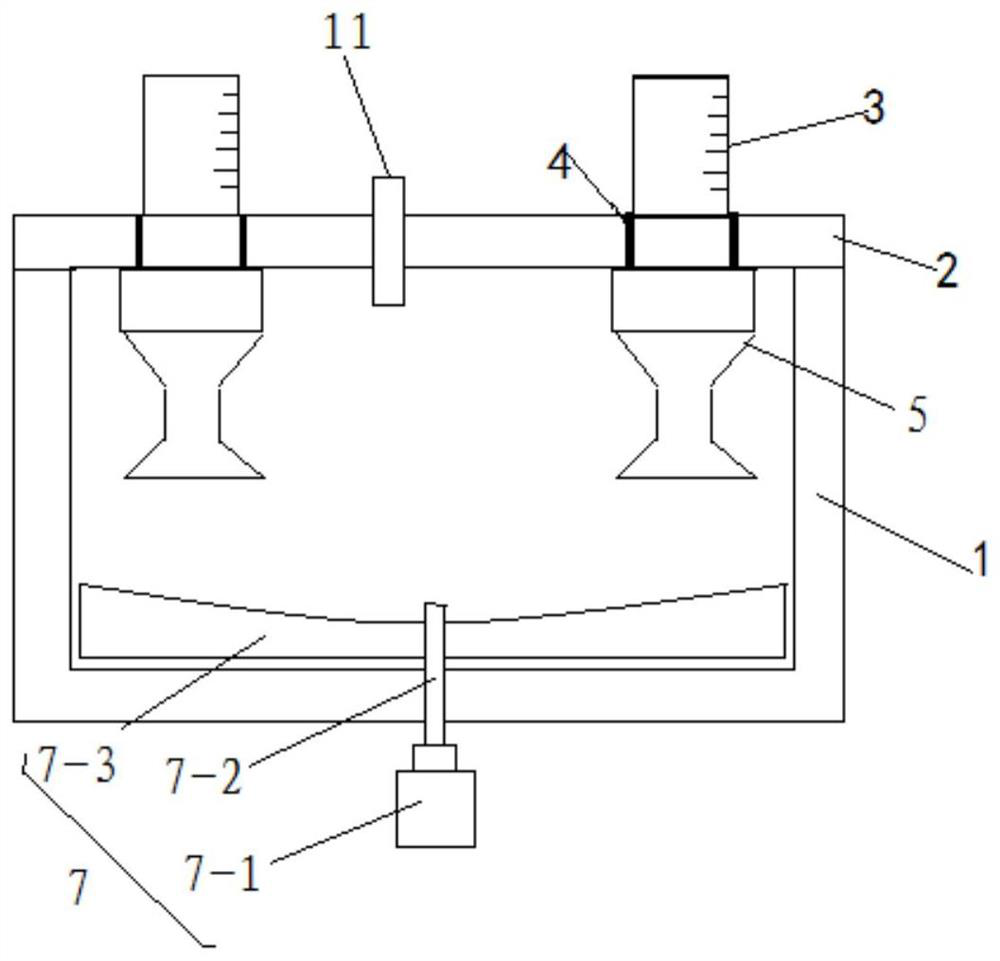

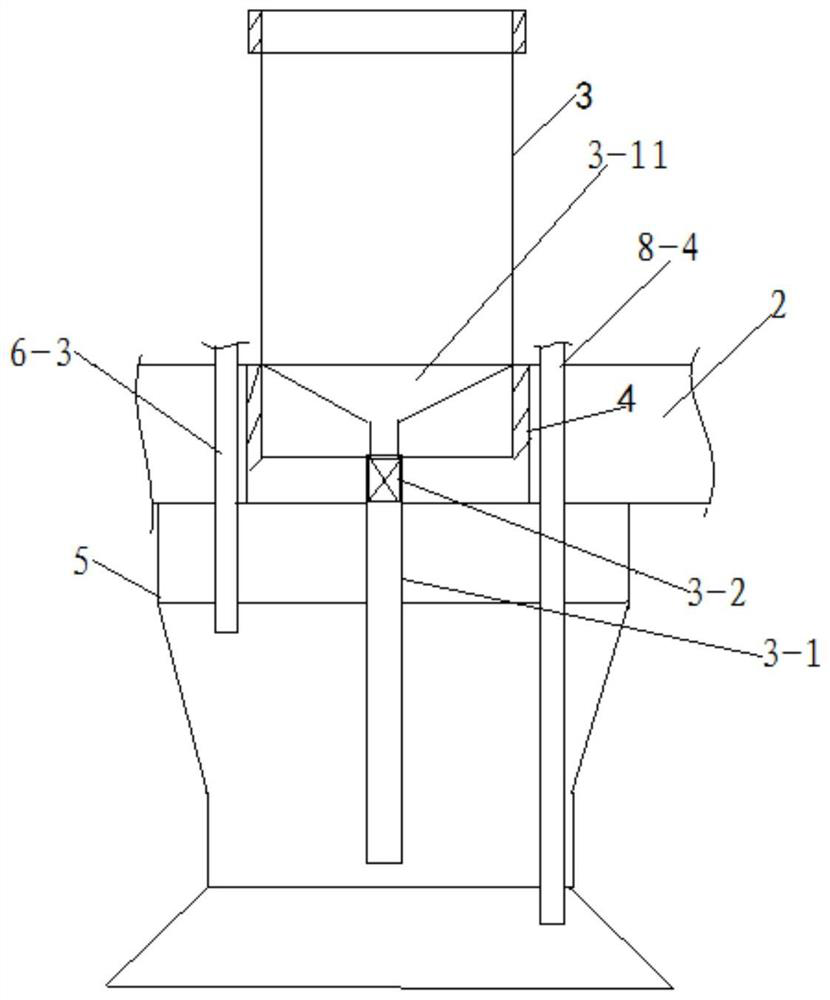

[0037] Such as Figure 1-3 As shown, the specific embodiment of the present invention is to be realized by adopting the following technical solutions, a kind of paint blending device for art pattern design, comprising a paint blending bucket 1; There are three first through-holes 4 along the longitudinal direction on the top; there are three quantitative pigment storage devices 3, which penetrate into each through-hole 4 from the upper port of each through-hole 4 along the longitudinal direction, and each through-hole is sealed and connected. The top of the paint storage device 3 is provided with an air hole communicating with the atmosphere, and the bottom wall of each quantitative paint storage device 3 is provided with an opening for the paint to flow out; there are three Venturi tubes 5, which are arranged longitudinally under each through hole 4 On the bottom wall of the bung 2 on the peripheral wall of the port, and the top of the Venturi tube 5 is sealed and connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com