Efficient architectural furniture timber cutting device

A cutting device and wood technology, applied in the direction of wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve the problems of poor wood flatness, wood bending deformation, wood cutting deformation, etc., to ensure accuracy, avoid deformation, Smooth wood cut surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

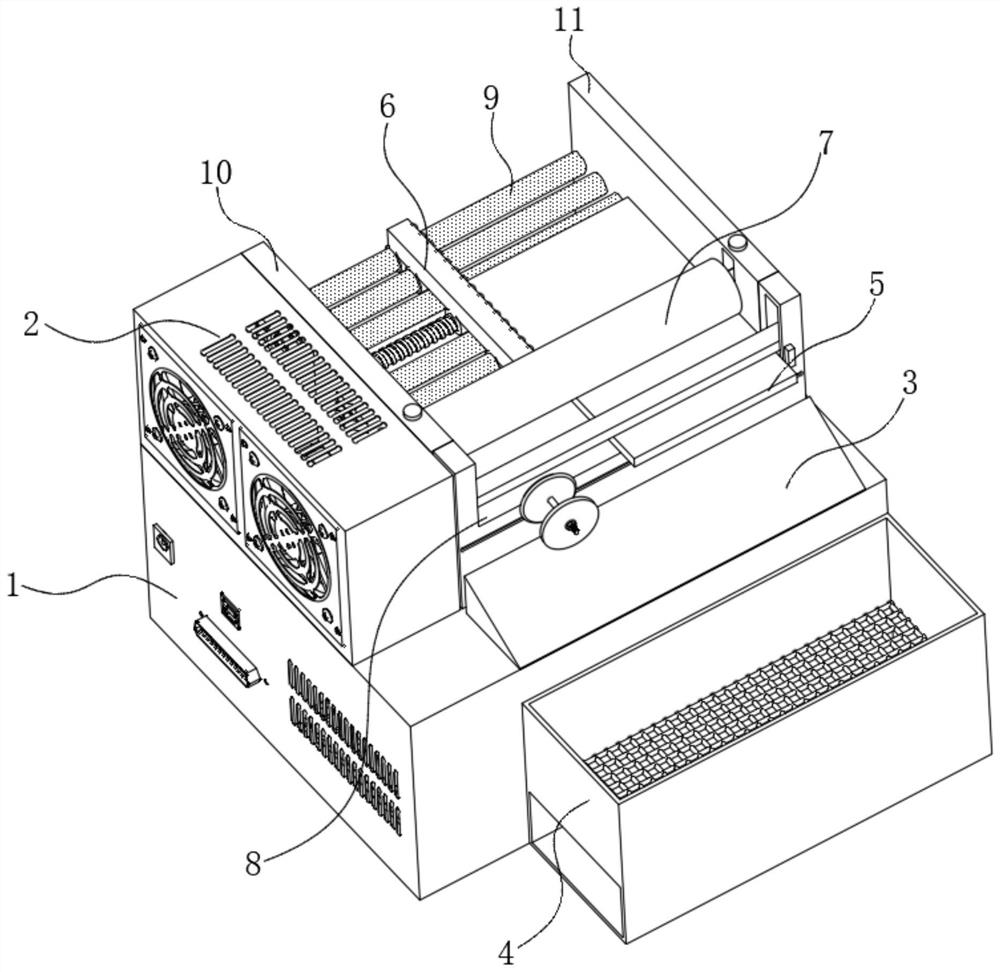

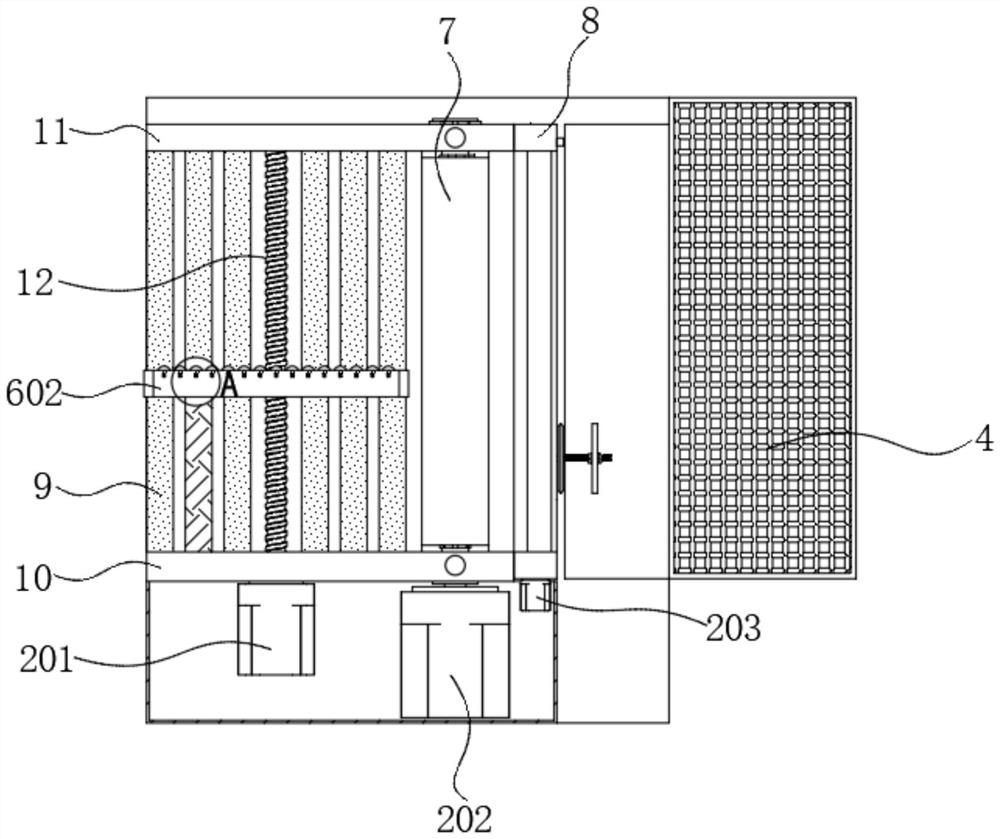

[0030] see Figure 1-7 , in an embodiment of the present invention, a high-efficiency building furniture wood cutting device includes a base 1, a straightening assembly 6, a conveying assembly 7, a cutting assembly 8 and a receiving assembly, wherein a power box 2 is fixed on the top side of the base 1 , used to provide power for the centralizing assembly 6, the conveying assembly 7 and the cutting assembly 8;

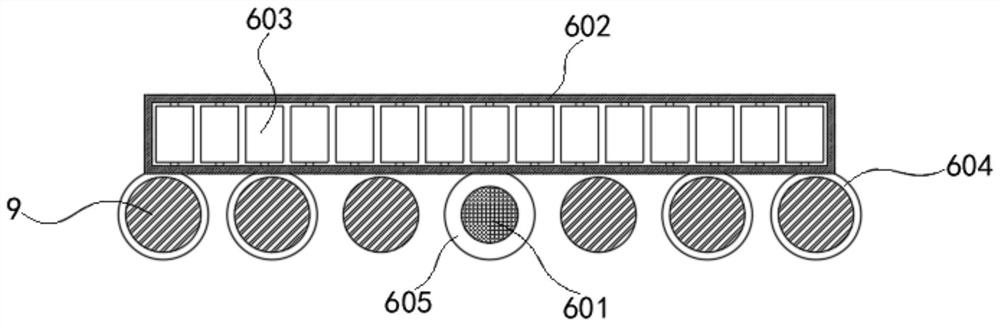

[0031] One side of the power box 2 is fixed with a side plate 10, and the opposite side of the side plate 10 is equipped with a side plate 11 fixed on the top of the base 1, and a screw is arranged between the side plate 10 and the side plate 11. One 12. The straightening assembly 6 and the conveying assembly 7, two sets of rollers 9 are symmetrically arranged on both sides of the screw 12, and each set of rollers 9 includes three rollers 9, and the side plate 10 The cutting assembly 8 is arranged on the right side of the second side plate 11, and the receiving assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com