Intelligent wrist equipment system of industrial robot and operation method thereof

A technology of industrial robots and robots, which is applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of multi-processing accumulation errors, large space utilization, and compact installation layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

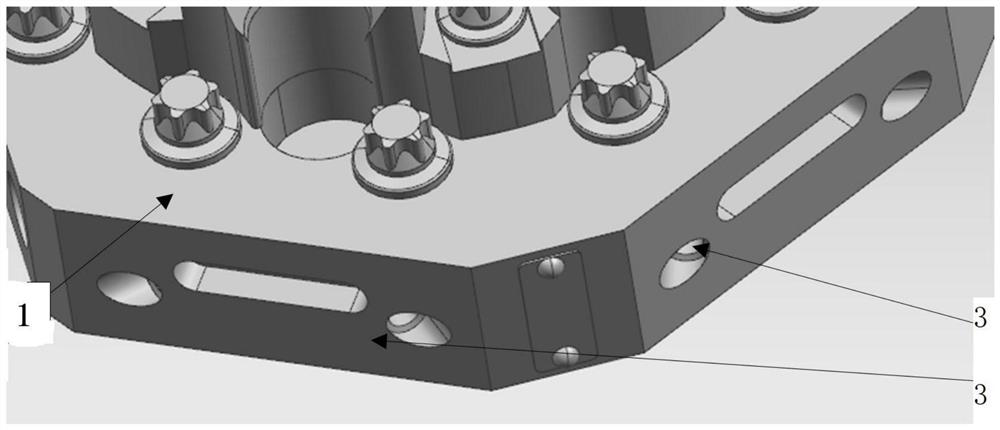

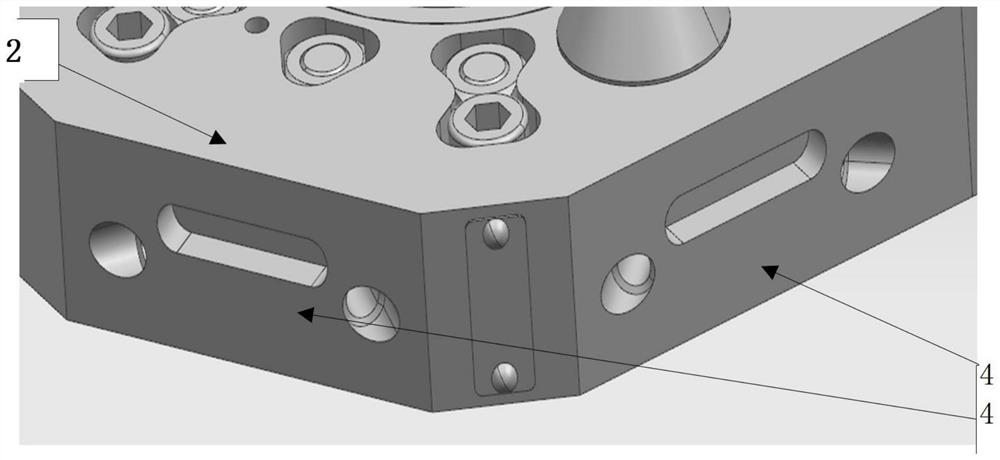

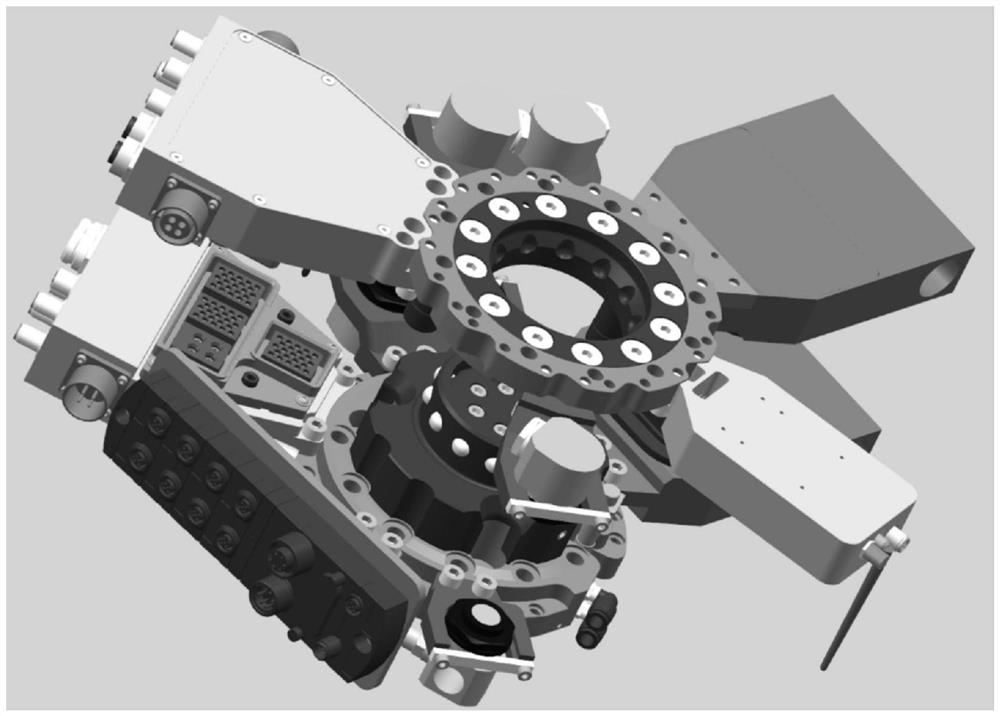

[0062] see image 3 as well as Figure 12 , the industrial robot intelligent wrist equipment system of the first embodiment includes: a robot side and a tool side, the robot side is fixed at the end flange of the robot, the tool side is locked on the robot side, and the tool sides are respectively fixed to realize various For tools with different functions, the robot side and the tool side form a one-to-many relationship. Through the macroscopic movement and microscopic capture movement of the robot side, different tools are taken out or replaced from the tool rack to realize the system function.

[0063] see Figure 4 , 6, 8 and Figure 9 , the robot side includes: robot side flange main body 11, robot side BK module 12, robot side electrical connection structure module 13, robot side welding module 14, robot side water and air module 15, robot side locking end 16, steel ball 17, robot side Side positioning hole 18, solenoid valve 19, pressure sensor 20, in-position sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com