Intelligent operation and maintenance machining production line for building steel members

A technology for building steel and production lines, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as low efficiency, and achieve the effects of convenient operation, saving labor costs, improving assembly efficiency and assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0055] Such as Figure 19 As shown, the product to be processed by the production line of the present invention is a building steel member, which includes a V-shaped connector 100, a reinforcing rib 101 is welded to the top of the V-shaped mouth, and an arc-shaped gap 102 is arranged on the reinforcing rib 101 and is connected with Hereinafter, the positioning ribs of the positive conductive plate 341 cooperate, and the two are welded and fixed by means of the principle of resistance welding, and the connecting parts on both sides of the V-shaped mouth are provided with mounting holes 103 .

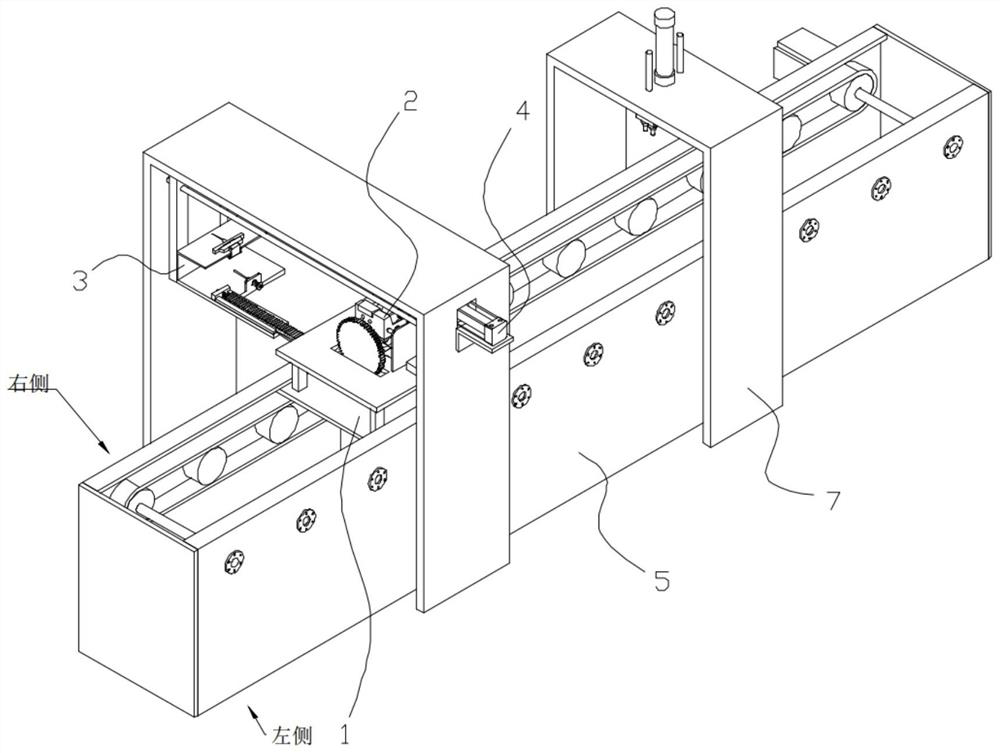

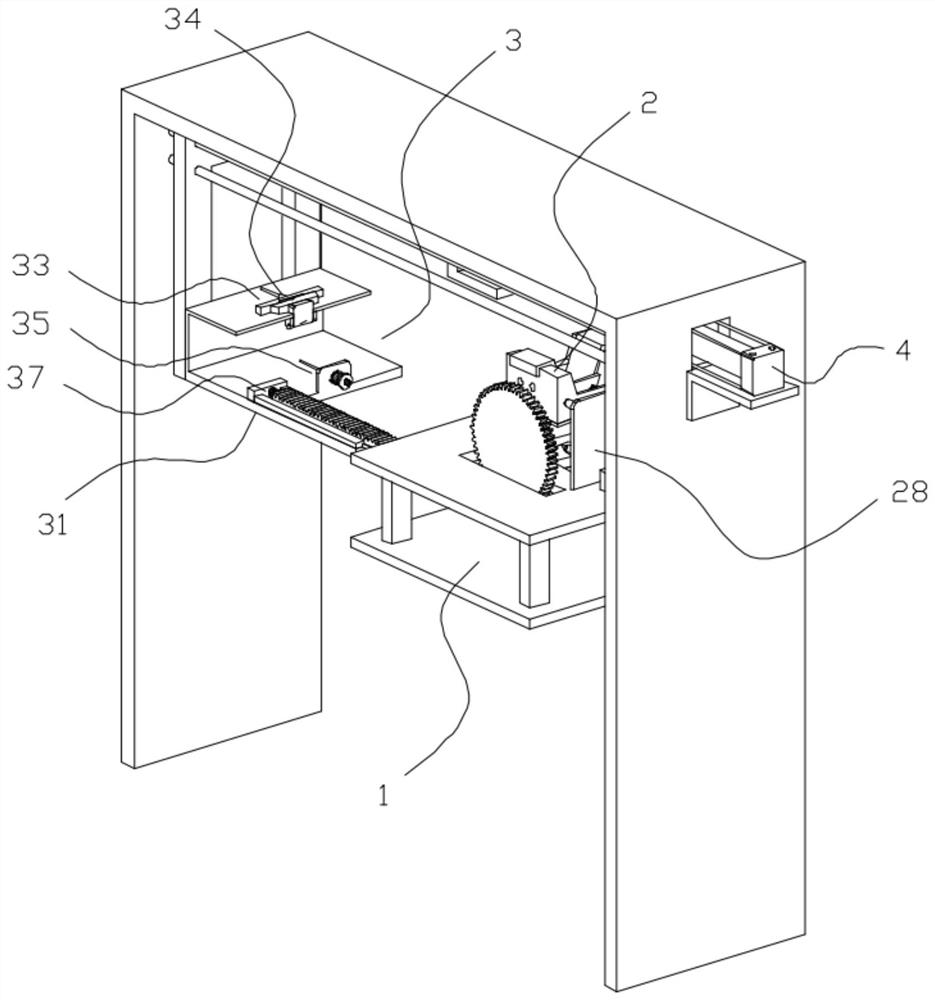

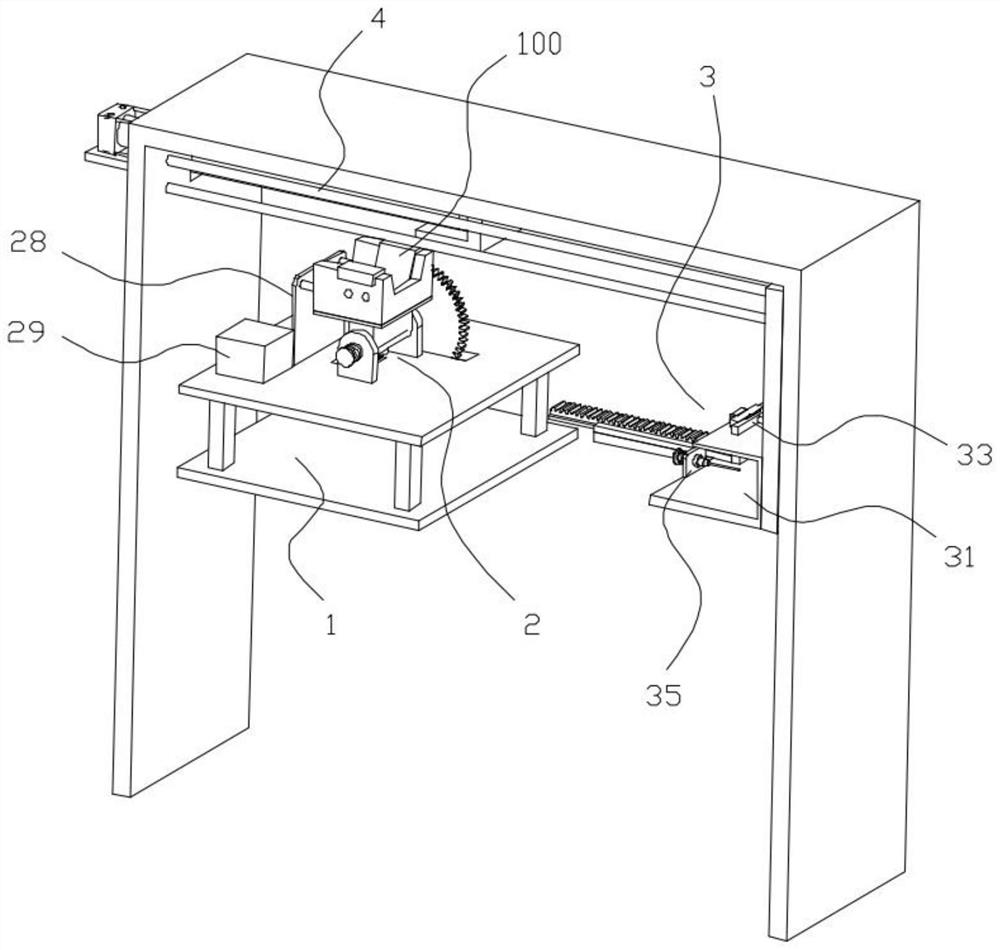

[0056] Such as Figure 1 to Figure 18 As shown, an intelligent operation and maintenance processing production line for building steel components, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com