Hemodialysis membrane and preparation method thereof

A technology of hemodialysis and membrane casting solution, which is applied in the field of hemodialysis membrane and its preparation, can solve the problems of complex process, difficulty in large-scale production, and performance degradation, and achieve the effects of cost reduction, strong hydrophilicity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A hemodialysis membrane prepared by the following method:

[0031] (1) Add 5g of 4,4'-dihydroxydiphenyl ether polysulfate (molecular weight: 50kDa) into 28.3g of N-methylpyrrolidone solution, stir and dissolve at 80°C, and then let it stand in a drying oven at 60°C. Degassing to obtain a uniform casting solution with a solid content of 15%;

[0032] (2) Pour the film-casting liquid onto a clean and smooth glass plate, scrape the film with a scraper to coat evenly, and after 30 seconds of natural volatilization, immerse the glass plate in methanol for a coagulation bath, and continue to place the film after the film falls off automatically. Soak it in deionized water for 24 hours.

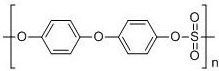

[0033] Wherein, the structural formula of 4,4'-dihydroxydiphenyl ether type polysulfate is:

[0034]

[0035] After testing, the pure water flux of the hemodialysis membrane prepared in Example 1 is 122 L m - 2 h -1 · bar -1 , the contact angle is 69°, when separating and concentratin...

Embodiment 2

[0037] A hemodialysis membrane prepared by the following method:

[0038] (1) Add 5g of 4,4'-dihydroxydiphenyl ether type polysulfate (molecular weight: 70kDa) to 28.3g of N-methylpyrrolidone solution, heat and stir at 80°C to dissolve, then put it in a drying oven at 60°C, Degassing to obtain a uniform casting solution with a solid content of 15%;

[0039] (2) Pour the film-casting liquid onto a clean and smooth glass plate, scrape the film with a scraper to coat evenly, and after 30 seconds of natural volatilization, immerse the glass plate in methanol for a coagulation bath, and continue to place the film after the film falls off automatically. Soak it in deionized water for 24 hours.

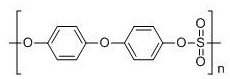

[0040] Wherein, the structural formula of 4,4'-dihydroxydiphenyl ether type polysulfate is:

[0041]

[0042] After testing, the pure water flux of the hemodialysis membrane prepared in Example 2 is 142L m - 2 h -1 · bar -1 , the contact angle is 59°, when separating and concentratin...

Embodiment 3

[0044] A hemodialysis membrane prepared by the following method:

[0045] (1) Add 5g of 4,4'-dihydroxydiphenyl ether type polysulfate (molecular weight: 100kDa) into 28.3g of N-methylpyrrolidone solution, heat and stir at 80°C to dissolve, then place it in a drying oven at 60°C, Degassing to obtain a uniform casting solution with a solid content of 15%;

[0046] (2) Pour the film-casting liquid onto a clean and smooth glass plate, scrape the film with a scraper to coat evenly, and after 30 seconds of natural volatilization, immerse the glass plate in methanol for a coagulation bath, and continue to place the film after the film falls off automatically. Soak it in deionized water for 24 hours.

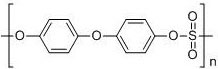

[0047] Wherein, the structural formula of 4,4'-dihydroxydiphenyl ether type polysulfate is:

[0048]

[0049] After testing, the hemodialysis membrane membrane pure water flux that embodiment 3 makes is 156L m - 2 h -1 · bar -1 , the contact angle is 59°, when separating and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com