Ground-source heat pump combined system for glass greenhouse

A ground source heat pump and composite system technology, applied in the field of glass greenhouse temperature control equipment, can solve the problems of large cooling load, affecting the growth and cultivation of vegetation in the greenhouse, and achieve high cooling efficiency, reduce frostbite or high temperature water loss, and good adjustment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

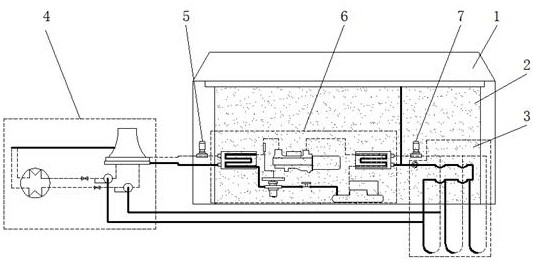

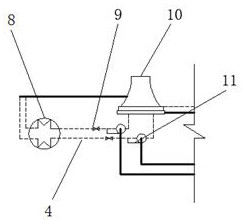

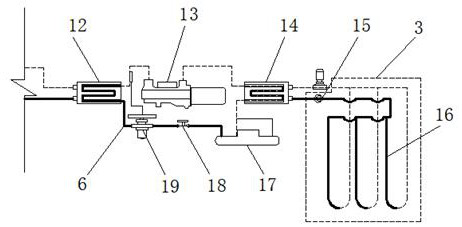

[0024] refer to Figure 1-3 , a ground source heat pump composite system for a glass greenhouse, comprising a glass greenhouse 1, a ground source heat pump assembly 6 located inside the glass greenhouse 1, a heat collection assembly 3 located at the bottom of the glass greenhouse 1, and a cooling tower located outside the glass greenhouse 1 Component 4, the outer wall of the glass greenhouse 1 is provided with a rollable sunshade net cover, the top and four sides of the glass greenhouse 1 are provided with ventilation windows, and a circulation pump 7 is connected between the ground source heat pump component 6 and the heat collection component 3. The upper liquid pump 5 is connected between the source heat pump assembly 6 and the cooling tower assembly 4, the cooling tower assembly 4 includes a cooling tower 10, a cooling pump 11 and a condenser 8, and the cooling tower 10 passes through the pipeline and the cooling pump 11, the condenser 8 to form a loop structure, the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com