Two-side cooling and evaporation coupling calculation method for liquid metal spiral tube steam generator

A steam generator and liquid metal technology, applied in design optimization/simulation, special data processing applications, etc., to achieve model independence and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

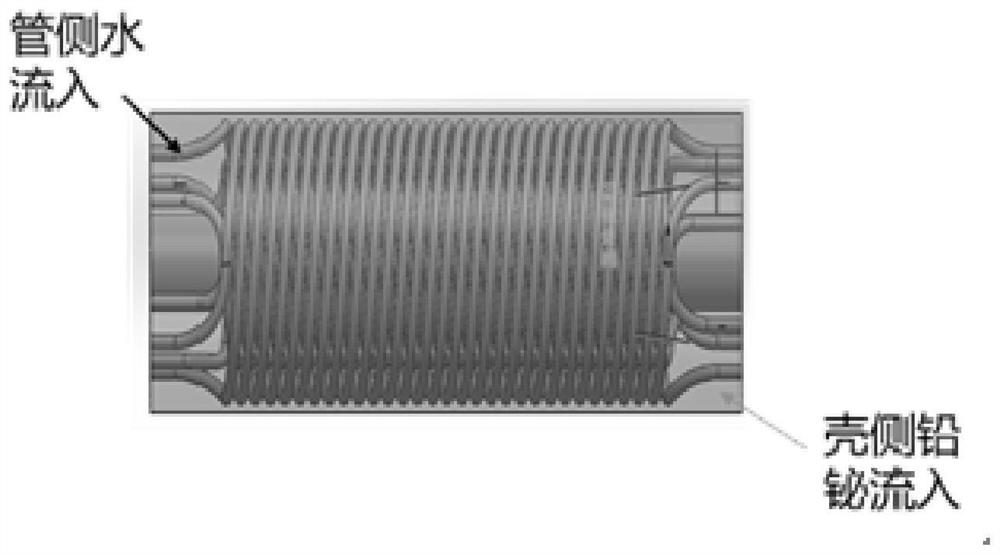

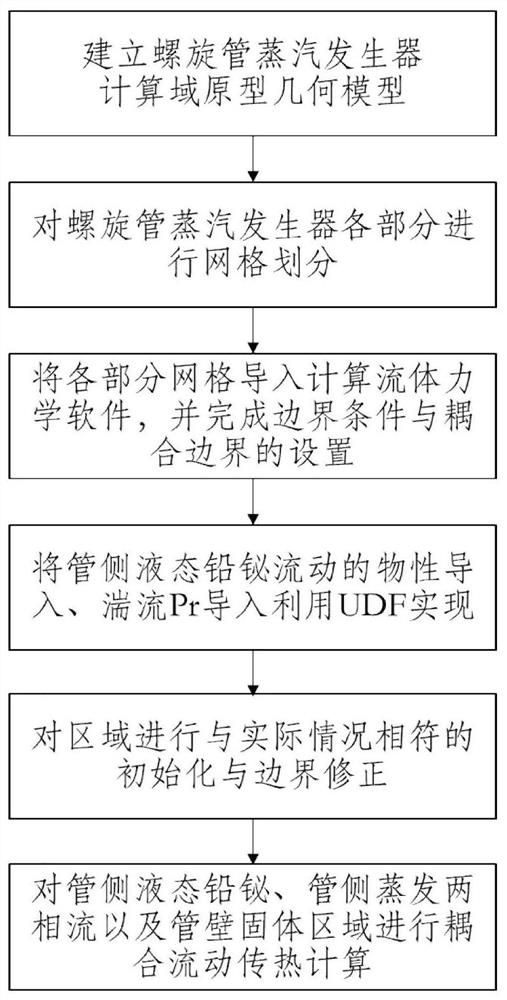

[0063] The following combination image 3 Shown in the flowchart, the calculation process of a typical multi-head helical tube steam generator is taken as an example to further describe the present invention in detail. The structure of a typical multi-head helical tube steam generator is as follows figure 1 As shown, the fluid flow directions on the shell side and the tube side are as follows figure 2 shown.

[0064] The coupling calculation method for the evaporation process of the liquid metal helical tube steam generator of the present invention comprises the following steps:

[0065] Step 1: Establish the prototype model of the computational domain of the helical steam generator, including the geometric model of the liquid metal fluid domain on the shell side of the helical steam generator, the geometric model of the two-phase fluid domain on the tube side of the helical steam generator, and the solid structure of the helical tube bundle wall structure Domain geometry m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com