Ultra-high-temperature strain field-temperature field synchronous measurement system and measurement method based on ultraviolet imaging

An ultraviolet imaging and synchronous measurement technology, which is applied in the fields of ultra-high temperature strain field-temperature field synchronous measurement and strain field-temperature constant synchronous measurement, which can solve the problem of unable to meet the needs of ultra-high temperature strain field-temperature field synchronous measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

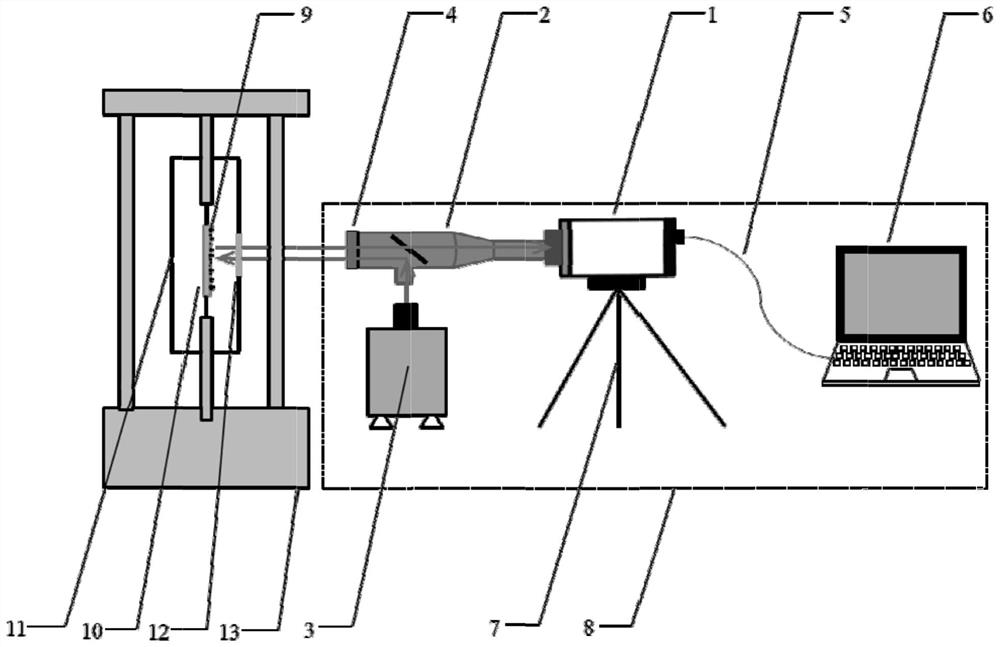

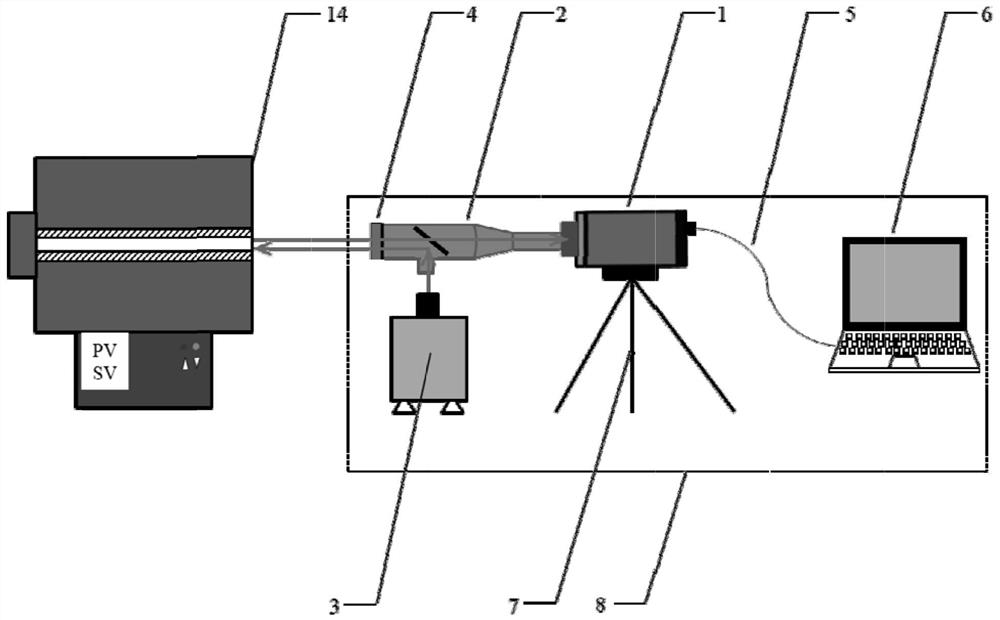

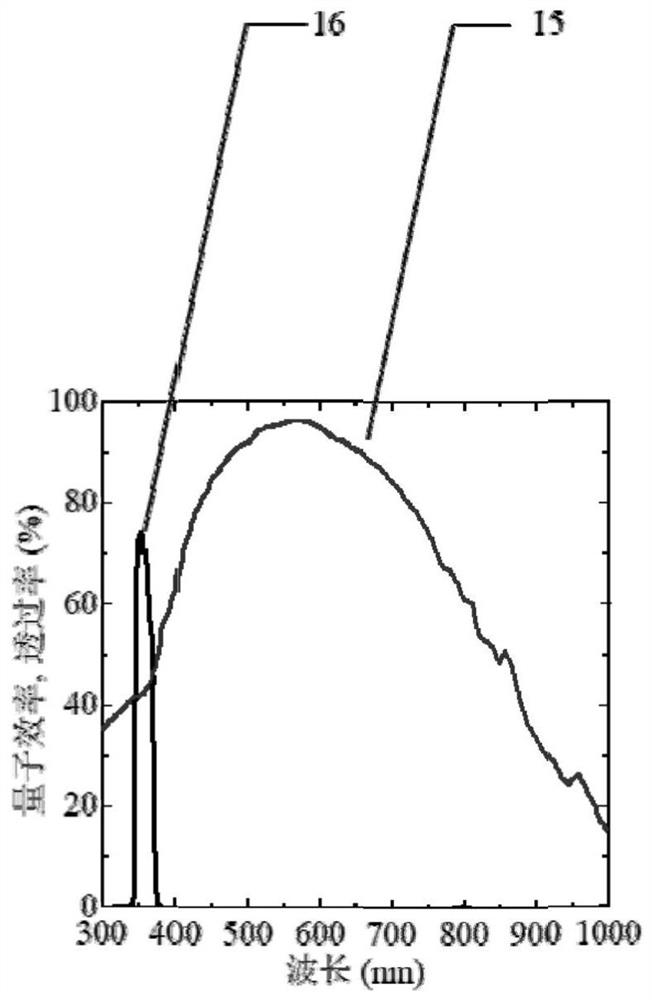

[0039] An ultra-high temperature strain field-temperature field measurement system and measurement method based on ultraviolet imaging, comprising: the system includes a coaxial ultraviolet imaging system 8, a mechanical test device 13, a high temperature furnace 11, an ultraviolet monochromatic light source 3, and a monochromatic light source Narrow band-pass filter 4 corresponding to the wavelength, camera 1, computer 6, tripod 7, data transmission line 5; coaxial ultraviolet imaging system 8 is used to collect clear images of the image surface through the optical sapphire glass observation window under ultra-high temperature conditions The mechanical test device 13 is used to load the test piece; the high temperature furnace 11 is used to heat up the test piece; the ultraviolet monochromatic light source 3 is used to generate high-intensity monochromatic light, from providing the test piece illumination, adjusting the clarity of the collected image; The band-pass filter 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com