Optical sensor

A technology for optical sensors and housings, applied in the field of sensors, can solve problems such as reduced service life, broken parts, and shaking of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

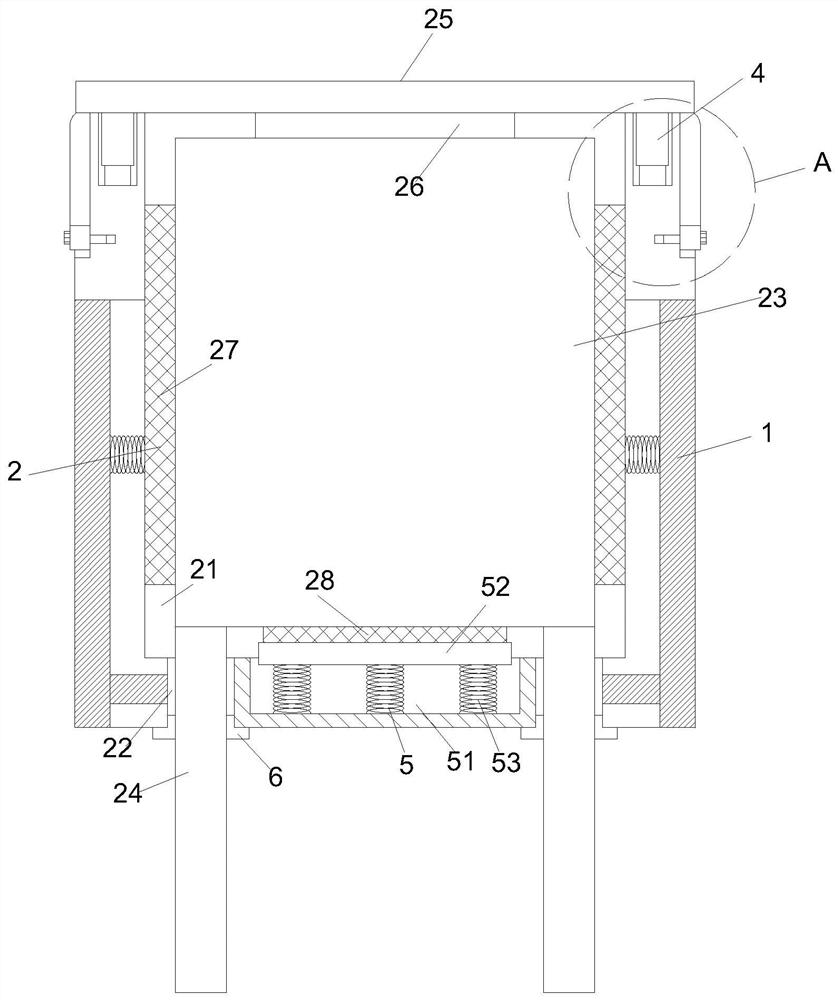

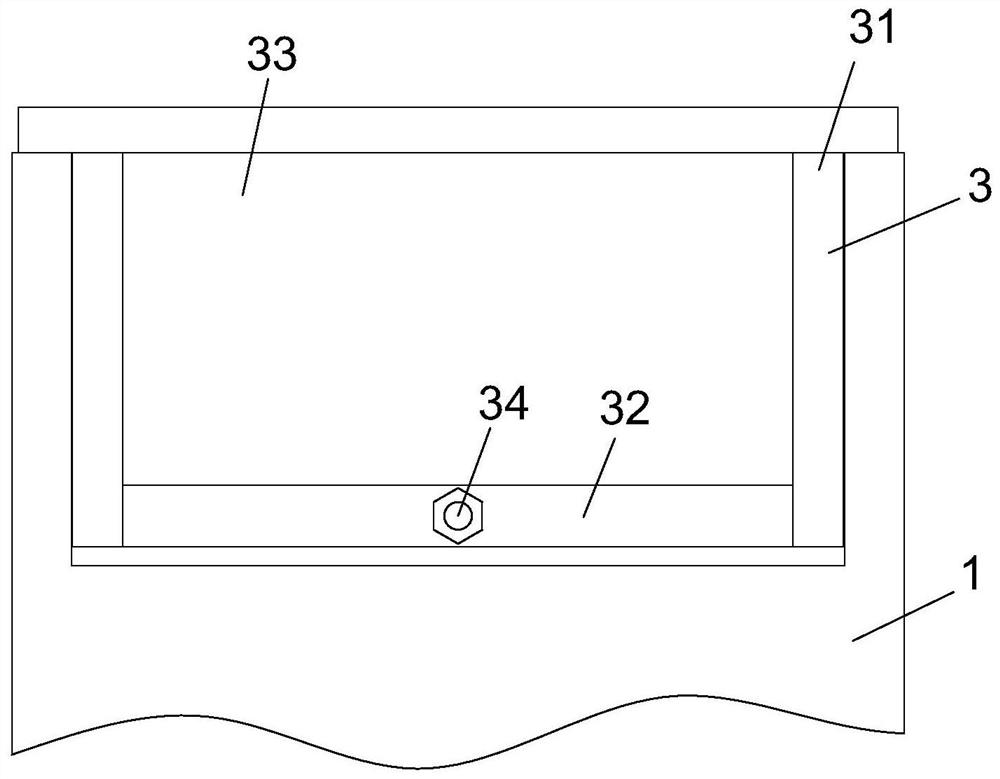

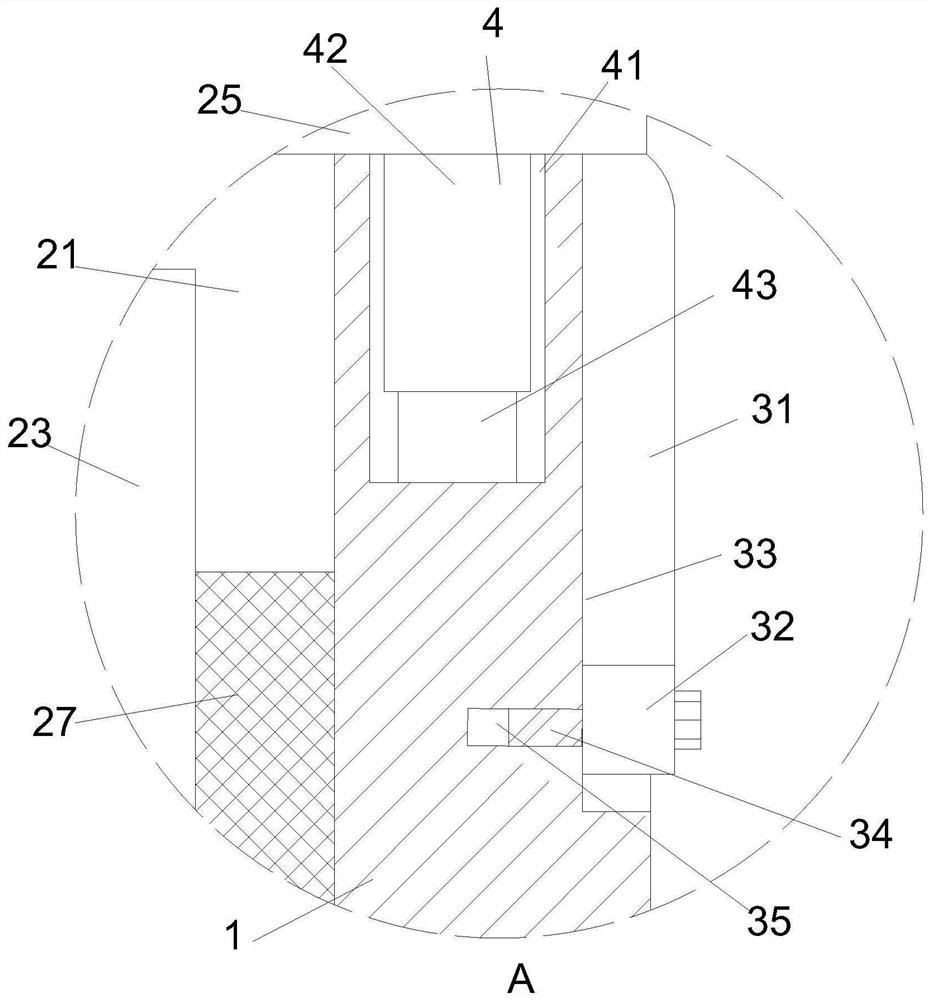

[0018] Please refer to figure 1 , figure 2 and image 3 , an optical sensor, including a housing 1, a mounting mechanism 2, a connecting mechanism 3, a sealing mechanism 4, an elastic mechanism 5 and a sealing plug 6, the mounting mechanism 2 is set in the housing 1, the mounting mechanism 2 includes a mounting groove 21, a through Port 22, optical sensor body 23, pins 24, cover plate 25, first buffer pad 26, second buffer pad 27 and third buffer pad 28, installation groove 21 is opened in housing 1, and port 22 is vertically opened On the lower side wall of the housing 1 and communicated with the inside of the installation groove 21, the optical sensor body 23 is located in the installation groove 21, and the pin 24 is fixedly installed on the lower end of the optical sensor body 23 and set through the opening 22, the cover plate 25 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com